Get the perfect fit! Learn about Custom-cut lengths and sliders Zippers, materials, ordering, and applications for any project.

Custom-cut lengths and sliders zippers give manufacturers the exact specifications they need without compromise. Unlike standard zippers that force you to work around predetermined lengths, custom-cut zippers are manufactured or modified to your exact requirements.

Key advantages of custom-cut zippers include:

- Perfect fit – No excess material or awkward modifications

- No waste – Order exactly what you need

- Design freedom – Access to specialized colors, materials, and finishes

- Professional results – Clean, finished appearance without alterations

- Cost efficiency – Eliminate material waste and labor for modifications

Standard zippers come in preset lengths like 12″, 18″, or 24″. But what happens when your jacket needs a 17.5″ zipper? Or your marine cover requires a 73″ separating zipper in a specific color? That’s where custom-cut solutions become essential.

As one customer noted after ordering 120-inch zippers for sleeping bags: “High quality and easy to slide. Exactly what I wanted in a timely manner.”

Custom zippers typically take around 2 weeks to manufacture, with minimum order quantities starting at 100 pieces for fully custom manufacturing. However, many suppliers offer custom-cutting of in-stock items with no minimums required.

The process involves specifying your exact length (often available in decimal increments), selecting the appropriate slider type, choosing materials and colors, and working with suppliers who understand industrial requirements.

The Anatomy of a Custom Zipper: Materials, Types, and Components

Before diving into custom-cut lengths and sliders zippers, it’s helpful to understand the basic building blocks. A zipper, at its core, consists of a few key components: the tape, the teeth (or coil), the slider, and the stops. But within each of these, there’s a universe of customization.

When we talk about custom zippers, we’re discussing the ability to select precise tape materials, choose from various teeth types, specify unique finishes, and define the exact gauge (size) of your zipper. This level of detail ensures your zipper isn’t just a fastener, but an integrated, high-performing part of your product.

Choosing the Right Zipper Material and Gauge

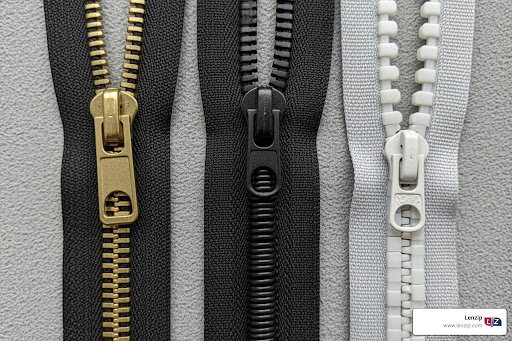

The material of your zipper teeth is crucial for its performance, durability, and aesthetic. We primarily work with three main types:

- Coil Zippers: These are made from a continuous spiral of monofilament nylon or polyester, stitched onto the zipper tape. They are incredibly flexible, lightweight, and often self-lubricating, making them ideal for a wide range of applications, from apparel to outdoor gear. Many coil zippers use PET (polyethylene terephthalate) tape, which adds to their durability and smooth operation.

- Molded Plastic Zippers: Featuring individual plastic teeth injected directly onto the zipper tape, molded plastic zippers are robust, durable, and resistant to corrosion. They are an excellent choice for outdoor applications, marine environments, upholstery, and heavier-duty items. Their strength makes them a go-to for projects needing a reliable, weather-resistant closure.

- Metal Zippers: Comprising individual metal teeth (typically brass, nickel, or aluminum) crimped onto the tape, metal zippers offer superior strength and a classic, premium appearance. They are often found in jeans, leather goods, and high-end fashion. Premium metal zippers, known for their polished appearance and smooth operation, are a showpiece in many high-end applications, adding a touch of elegance and reliability.

Beyond the material, the zipper gauge is another critical specification. This refers to the width of the zipper teeth, in millimeters, when the zipper is fully closed or “zipped.” The gauge determines the zipper’s strength and suitability for different applications:

- #2 Gauge: Often used for invisible zippers, offering a discreet closure.

- #3 Gauge: A lightweight option, commonly found in dresses, skirts, and smaller pockets.

- #5 Gauge: Our most versatile, medium-weight zipper, suitable for a vast array of garments, bags, and everyday items.

- #8 Gauge: A heavy-duty choice, perfect for items like awnings, cushions, upholstery, and heavier jackets, where durability is paramount.

- #10 Gauge: The heaviest duty option, designed for extreme applications such as tents, sleeping bags, and industrial uses requiring maximum strength.

Selecting the right material and gauge hinges entirely on your project’s specific requirements. For instance, a lightweight jacket might call for a #5 coil zipper, while a rugged outdoor backpack would benefit from a #8 molded plastic or metal zipper.

Zipper Material | Strength | Flexibility | Common Uses |

Nylon Coil | Medium | High | Apparel, outdoor gear, bags, sleeping bags |

Molded Plastic | High | Medium | Outdoor, marine, upholstery, luggage |

Metal | Very High | Low | Jeans, leather goods, high-end fashion |

Open-End vs. Closed-End: What’s the Difference?

When specifying your custom zipper, one of the most fundamental decisions is its end-type. This dictates how the zipper functions and separates (or doesn’t).

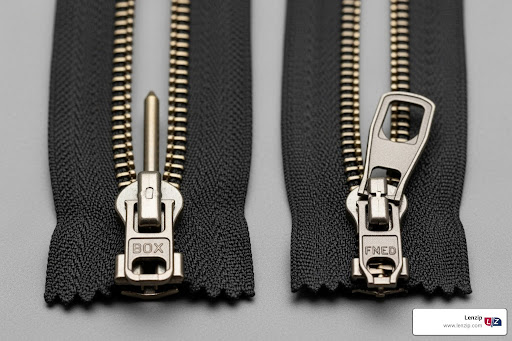

- Open-End Zippers (Separating Zippers): These zippers are designed to completely separate into two distinct halves when unzipped. They feature a “pin insert” on one side and a “retainer box” on the other at the bottom, allowing the two sides to detach fully. The most common application for open-end zippers is on the front of jackets, where the garment needs to open completely. We can also provide two-way open-end zippers, which are excellent for heavy winter coats, allowing for adjustable ventilation and comfort by opening from both the top and bottom.

- Closed-End Zippers: Unlike their open-end counterparts, closed-end zippers remain permanently joined at one or both ends. They are ideal for applications where the opening doesn’t need to fully separate. Think of the zippers on pants, sleeves of leather jackets, purses, tents, or internal pockets. We also offer “bag style” zippers, which are typically closed-end and often feature two sliders for quick access from either side, commonly used for bags or applications requiring broad access. Bridge-top zippers, a type of closed-end zipper, are perfect for pockets or inside of purses.

Understanding these distinctions is key to ensuring your custom zipper functions exactly as intended for your product. For more detailed definitions, you can refer to our Zipper Terminology guide.

Understanding Slider Types and Functionality

The slider is the heart of the zipper, the component that brings the teeth together or separates them. But not all sliders are created equal. The type of slider you choose significantly impacts the zipper’s functionality and user experience.

- Autolock Sliders (Locking Sliders): These are the workhorses of the apparel world. Autolock sliders have a small mechanism inside that “locks” the slider in place on the teeth unless the pull tab is lifted. This prevents the zipper from unintentionally sliding down, making them ideal for garments like jackets, pants, and dresses where you want the zipper to stay put.

- Non-lock Sliders: As the name suggests, non-lock sliders move freely along the zipper chain without a locking mechanism. They are commonly used in applications where quick and easy movement is desired, such as bags, tents, sleeping bags, and other non-garment items.

- Reversible Sliders: These sliders are designed to be operated from either side of the zipper tape, making them perfect for reversible garments or items where the zipper needs to be accessible from both the interior and exterior.

- Double-Pull Sliders: Featuring two pull tabs on a single slider body, these are often used on two-way zippers (where two sliders operate on the same chain) or on items where the zipper needs to be pulled from either direction (e.g., a sleeping bag that opens from the inside or outside).

- Custom Pullers: Beyond functionality, sliders offer a fantastic opportunity for branding. We can provide custom pullers that are personalized to express your brand identity, adding a unique touch and reinforcing your product’s aesthetic. Whether it’s a specific shape, logo, or finish, custom pullers lift your product’s perceived value.

It’s crucial to remember that sliders are specific to zipper coil sizes and types. A slider for a #5 metal zipper will not work on a #5 nylon coil zipper, and vice-versa. Ensuring compatibility is paramount for a smoothly functioning zipper. We offer a wide range of colors for sliders, often matched to popular industry color codes, allowing you to seamlessly integrate them into your design.

The Ultimate Guide to Custom-cut lengths and sliders Zippers

The beauty of custom-cut lengths and sliders zippers lies in their precision. No more wrestling with excess zipper length or unsightly modifications. This section guides you through the practicalities of ordering, from accurate measurement to understanding costs and lead times.

How to Measure for a Perfect Fit

Accurate measurement is the cornerstone of ordering custom zippers. A millimeter can make all the difference between a perfect fit and a frustrating struggle. Here’s how we advise our clients to measure:

- Measuring Closed-End Zippers: For closed-end zippers (like those on pants, bags, or sleeves), you should measure the distance from the very bottom of the bottom stop (the metal or plastic piece at the base of the zipper teeth) to the very top of the top stop (the corresponding piece at the top). This “stopper-to-stopper” measurement is the true functional length of the zipper. Do not measure the fabric tape beyond the stops.

- Measuring Separating Zippers (Open-End): For separating zippers (like those on jackets), measure from the very bottom of the pin insert (the pin that slides into the retainer box) to the very top of the top stop. Again, this is the functional length of the zipper teeth, not the overall length of the fabric tape.

We can accommodate custom lengths in precise increments, often down to decimal inches (e.g., 17.5 inches or 3.25 inches), ensuring your zipper is truly bespoke.

Common mistakes to avoid:

- Measuring the entire fabric tape: The extra fabric at the ends is for sewing into seams and is not part of the functional length.

- Not accounting for seam allowance: Always factor in how much of the zipper will be sewn into the product when determining the exposed length you need.

- Assuming standard sizes: While some projects might fit standard sizes, custom orders are for when they don’t. Don’t try to force a standard size if your project needs something unique.

Key Factors in Ordering Custom-cut lengths and sliders Zippers

Once you’ve mastered the art of measurement, understanding the practical aspects of ordering will streamline your process.

- Minimum Order Quantities (MOQs): For fully custom-manufactured zippers, which are built from scratch to your exact specifications, we typically require a minimum order quantity. This often starts around 100 pieces or more, though some highly specialized styles might have higher minimums. However, for smaller quantities, we can often custom-cut in-stock zipper chain to your desired length with no minimum purchase required, offering immense flexibility for prototyping or small-batch production.

- Turnaround Times: Custom zippers are made to order, but we pride ourselves on efficiency. Most custom orders have a lead time of approximately 2 weeks for manufacturing. More complex styles or very large orders might require a slightly longer lead time, but we always strive for prompt delivery. Our in-house manufacturing capabilities allow us to manage production times effectively and even expedite orders when necessary, without compromising on our renowned quality.

- Cost Factors: The cost of your custom zipper order is influenced by several variables:

- Material: Premium materials (like certain metal types) or specialized components can affect the price.

- Length: Longer zippers naturally require more material.

- Quantity: We offer attractive bulk ordering discounts. For example, you might see discounts starting at 10% off for 10-49 units and 20% off for 50+ units on certain custom products. This makes custom solutions more cost-effective for larger production runs.

- Finish: Specialized finishes or coatings can also be a factor.

- Custom Color Options (Tape and Teeth): Customization extends to aesthetics. We can provide custom zippers with specific color tape, matched to your brand’s palette or design vision. Many suppliers offer over 600 custom color options for tape, ensuring a perfect match. For metal zippers, you can also select the finish of the teeth (e.g., antique brass, nickel, gunmetal, polished gold, or silver) to complement your design.

Ready to get started? You can easily Request a Quote for your custom zipper project. For our US-based customers, understanding potential import duties is important, and you can use a (US Only) 25% Tariff Calculator to estimate any reciprocal tariffs that might apply to imported goods, further highlighting the benefit of sourcing domestically.

Applications: Where Custom Zippers Make a Difference

When you’re working on a project that demands precision, custom-cut lengths and sliders zippers become more than just functional hardware—they become the difference between “good enough” and exceptional. The real magic happens when these zippers are put to work across industries where standard solutions simply fall short.

Every industry has its unique challenges, and zippers need to rise to meet them. Whether it’s a fashion designer who needs that perfect 17.5-inch length for a jacket, or a marine manufacturer requiring a 73-inch separating zipper that can handle saltwater exposure, custom solutions deliver where standard options leave you compromising.

The beauty of custom zippers lies in their ability to solve problems you didn’t even know you had. No more cutting off excess length, no more unsightly modifications, and no more settling for “close enough” when your project deserves perfection.

Why Choose Custom-cut lengths and sliders Zippers for Your Project?

In fashion and apparel, every millimeter matters. Designers know that a perfectly fitted zipper can make or break a garment’s silhouette. Custom zippers allow for precise lengths that eliminate bulky alterations while opening up a world of aesthetic possibilities. Picture a sleek evening gown with an invisible zipper cut to exactly 22.75 inches, or a statement leather jacket featuring a bold metal zipper with custom pullers that showcase the brand’s identity. These details don’t just improve function—they become part of the design story.

When it comes to outdoor gear and marine applications, durability isn’t optional—it’s survival. A sleeping bag manufacturer recently ordered 120-inch zippers from us, knowing that standard lengths would never work for their oversized bags. Marine covers, boat cushions, and outdoor tents face relentless exposure to sun, salt, and storms. Custom-cut zippers in these applications use heavy-duty gauges and weather-resistant materials that stand up to whatever nature throws at them. The precision length ensures optimal performance and weatherproofing that keeps the elements where they belong.

The upholstery and furniture industry has finded that custom zippers are a game-changer for both quality and efficiency. Instead of wrestling with standard lengths that never quite fit, manufacturers can order continuous zipper chain and cut exact lengths for each piece. This approach dramatically reduces waste while ensuring every cushion cover and furniture piece has that clean, professional finish that customers expect. It’s particularly cost-effective for larger production runs where every inch of saved material adds up.

Luggage and bags demand zippers that work smoothly thousands of times without fail. A stuck zipper on a suitcase at the airport isn’t just inconvenient—it’s a brand reputation issue. Custom-cut zippers for luggage often feature non-lock sliders for easy access and robust gauges that handle the constant stress of travel. Custom pullers also provide branding opportunities that turn functional hardware into marketing tools.

In military and industrial applications, failure isn’t an option. These environments demand zippers that meet strict specifications for strength, durability, and sometimes specialized certifications. Think hazmat suits requiring precise sealing, military gear that must perform in extreme conditions, or fire safety equipment needing materials that can handle high heat. Custom solutions ensure these critical applications get exactly the performance characteristics they need, with rigorous quality control that lives up to the demanding standards.

For technical specifications and material details that might apply to your specific application, our Webbing Terminology guide provides additional insights into the components that make these solutions possible.

The common thread across all these applications is the understanding that when your project has specific requirements, custom solutions deliver results that standard options simply can’t match. Whether it’s improving functionality, enhancing aesthetics, or meeting industry-specific demands, custom-cut lengths and sliders zippers transform ordinary products into extraordinary ones.

Frequently Asked Questions about Custom Zippers

When you’re considering custom-cut lengths and sliders zippers for your project, it’s natural to have questions. We’ve been helping customers steer these decisions for over 80 years, so let us share some insights on the most common concerns that come up.

What are the main advantages of custom-cut zippers over standard-length ones?

The biggest game-changer is getting exactly what you need, when you need it. Standard zippers come in those familiar lengths – 12 inches, 18 inches, 24 inches. But what happens when your marine cover needs a 37-inch zipper, or your custom jacket calls for 19.5 inches? That’s where custom solutions really shine.

Perfect fit means no more wrestling with excess zipper length or making awkward modifications that never quite look right. When you order the exact length, your finished product looks professional and clean. One customer told us, “Finally, a zipper that fits like it was meant to be there – because it was!”

Eliminating waste is another huge benefit. Why pay for 24 inches when you only need 17? With custom-cut zippers, you order precisely what your project requires. For manufacturers running larger productions, this translates into real cost savings and a more sustainable approach.

The design freedom aspect often surprises people. You’re not stuck with whatever colors and finishes happen to be available in standard lengths. Want a specific shade of blue tape with brass teeth? Or maybe a custom puller that matches your brand? Custom zippers open up possibilities that simply don’t exist with off-the-shelf options.

While the individual zipper might cost slightly more upfront, the overall efficiency usually makes custom the smart choice. No labor costs for modifications, no material waste, and a superior finished product that reflects the quality of your work.

Can I order just one custom zipper?

This depends on what type of customization you need, and we’re happy to work with projects of all sizes.

If you need a fully custom-manufactured zipper – something with unique specifications like a special gauge, unusual material combination, or completely custom colors – we typically have minimum order quantities starting around 100 pieces. This is because creating something truly unique requires setting up specialized production runs.

But here’s the good news: if you need a specific length of something we already stock, we can often custom-cut individual zippers with no minimum. Need a single 27.5-inch zipper from our #5 black coil stock? We can make that happen. This is perfect for repairs, prototypes, or one-off projects.

Many customers start with a single custom-cut zipper to test their design, then place larger orders once they’re confident in the specifications. It’s a practical way to ensure everything fits perfectly before committing to a full production run.

What is the difference between a locking and non-locking slider?

The difference comes down to whether you want your zipper to stay put or move freely, and choosing the right one can make or break your product’s functionality.

Locking sliders (also called autolock sliders) have a small internal mechanism that grips the zipper teeth when the pull tab is down. You have to lift the tab to move the slider. These are essential for garments – imagine a jacket zipper that kept sliding down every time you moved! The locking feature prevents embarrassing wardrobe malfunctions and keeps everything securely in place.

Non-locking sliders move freely along the zipper without any resistance. They’re perfect for applications where you want quick, easy access. Think bags, tents, sleeping bags, or cushion covers. When you’re trying to get into your tent quickly during a rainstorm, the last thing you want is a finicky tab you have to lift every time.

The choice really depends on your product’s purpose. If it’s something people wear or where security matters, go with locking. If it’s about quick access and convenience, non-locking is usually the way to go. We’ve seen customers choose the wrong type and end up frustrated with how their finished product performs, so it’s worth getting this decision right from the start.

Conclusion: Your Partner for High-Quality Custom Zippers

When you’re working on a project that demands precision, custom-cut lengths and sliders zippers aren’t just a nice-to-have—they’re essential. Whether you’re designing a high-end jacket that needs a 17.5″ zipper or manufacturing marine covers that require 73″ separating zippers, the right custom solution makes all the difference between a professional finish and a compromised product.

Finding a reliable supplier is key to project success. You need more than just someone who can cut a zipper to length. You need a partner who understands that a #5 metal slider won’t work on a #5 coil zipper, who knows the difference between stopper-to-stopper measurements and overall tape length, and who can guide you through material choices that will stand up to your specific application.

The benefits of high-quality manufacturing extend far beyond the immediate project. When your zippers perform flawlessly—whether they’re autolock sliders on winter jackets or heavy-duty #10 gauge zippers on industrial equipment—your customers notice. That reliability builds trust in your brand and keeps people coming back.

US-based production offers distinct advantages in today’s market. It means shorter lead times, better communication, consistent quality control, and the ability to make adjustments quickly when your project needs change. There’s something reassuring about knowing exactly where your components come from and having direct access to the people who make them.

For over 80 years, Lenzip has provided unparalleled quality and on-time delivery for commercial and industrial zipper needs. We’ve seen trends come and go, materials evolve, and applications expand into industries that didn’t even exist when we started. Through it all, our commitment has remained the same: delivering exactly what you ordered, when you need it, every single time.

From fashion designers who need invisible zippers in precise custom lengths to military contractors requiring specialized materials that meet strict specifications, we understand that your project’s success depends on getting the details right. That’s why we take the time to understand your requirements, offer guidance on materials and measurements, and manufacture each zipper with the same attention to detail we’d want in our own products.

Ready to see what custom can do for your project? Explore our custom zipper products and find how the perfect fit can lift your work from good to exceptional.