Dive Deep:

Choosing the Right Marine Grade Zippers

Unzip the world of continuous chain zipper. Learn types, sizes, materials, and how to assemble custom industrial & specialty zippers.

Dive Deep: Choosing the Right Marine Grade Zippers

Unlock marine zippers! Get expert tips on selecting, maintaining, and repairing boat zippers for harsh marine environments.

Marine zippers are specialized fasteners designed to withstand the harsh conditions of saltwater environments, UV exposure, and constant moisture that would destroy standard zippers in months.

Quick Guide to Marine Zippers:

• Common Sizes: #5 (small applications), #8 (production manufacturers), #10 (custom covers and heavy-duty use)

• Top Brands: Lenzip (lifetime warranty), and other leading brands.

• Key Features: UV-resistant materials, corrosion-resistant components, saltwater protection

• Main Types: Coil (flexible, curved applications) vs. Vislon/molded tooth (stronger, straight applications)

• Slider Materials: Plastic (saltwater resistant, can fatigue) vs. Metal (stronger, needs maintenance)

Choosing the wrong zipper for boat covers, bimini tops, or marine enclosures can cost you hundreds in replacements and unhappy customers. For example, a broken 30-foot zipper on a sail cover can cost hundreds to replace professionally—a problem avoided by choosing the right marine-grade zipper from the start.

Marine environments are brutal on equipment. Sun exposure breaks down standard plastic components, while saltwater corrodes metal parts and constant moisture creates the perfect storm for zipper failure. That’s why marine zippers use specialized resins treated with UV inhibitors and corrosion-resistant materials that regular zippers simply don’t have.

The most common marine zipper sizes are #10 for heavy-duty applications like boat covers, #8 for production manufacturing, and #5 for lighter applications. Each size serves specific needs, and choosing wrong can mean premature failure or unnecessary bulk.

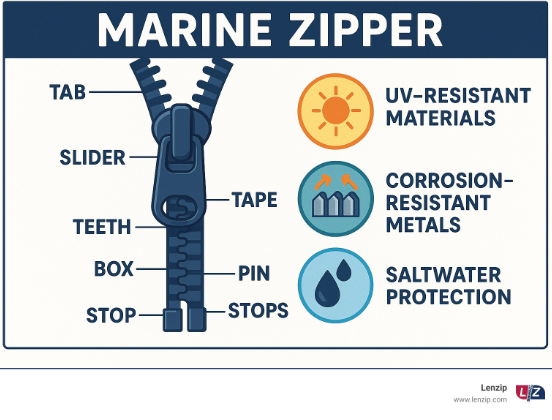

Decoding the Anatomy of a Marine Zipper

Think of a marine zipper like a well-orchestrated team – every part has a job, and when one fails, the whole system breaks down. Understanding how these components work together isn’t just technical knowledge; it’s the key to choosing the right zipper and keeping it running smoothly for years.

Let’s start with the slider – that’s the part you actually grab and move. It’s doing all the heavy lifting, forcing those teeth to mesh together or separate as you pull. The tab (sometimes called a pull) is your handle on the slider, and in marine applications, you’ll want something substantial enough to grip with wet or gloved hands.

The teeth are where the magic happens. These interlocking pieces create the actual closure, and they come in two main styles we’ll explore in detail below. The tape is the fabric backbone that holds everything together – and in harsh marine conditions, it needs to be tough as nails.

For separating zippers (the kind that fully open at the bottom), you’ll find a box and pin system. The pin slides into the box to start the zipper, kind of like threading a needle. Finally, top stops and bottom stops are the little guards that keep your slider from flying off the end – trust me, you don’t want to lose those overboard.

If you want to dive deeper into zipper terminology, check out our comprehensive guide on zipper parts. It’s surprisingly fascinating once you get into it.

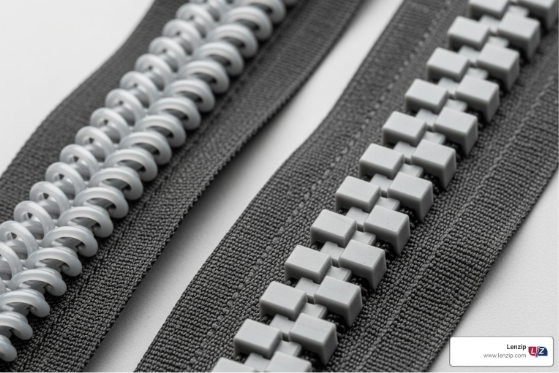

Zipper Types: Coil vs. Molded Tooth

Here’s where things get interesting. Not all marine zippers are built the same way, and the difference comes down to how those teeth are made.

Coil zippers use a continuous spiral of nylon or polyester – imagine a tiny spring stretched out and sewn to tape. This design makes them incredibly flexible, perfect for boat covers that need to bend around corners or follow curved surfaces. The continuous nature means there are no individual weak points, though the coil itself can be damaged if you’re rough with it.

Molded tooth zippers take a completely different approach. Each tooth is individually formed and attached to the tape, creating a strong and durable closure that can handle serious stress. They’re the workhorses of the zipper world – less flexible than coil types, but built to last in demanding applications.

The choice between them often comes down to your specific needs. Curved application? Go coil. Need maximum strength in a straight line? Molded tooth is your friend.

What Makes a Zipper “Marine Grade”?

Here’s the million-dollar question: what transforms a regular zipper into a marine-grade warrior that can handle salt spray, blazing sun, and constant moisture?

The secret starts with UV resistance. Regular plastic turns chalky and brittle under constant sun exposure – you’ve probably seen this on old outdoor furniture. Marine zippers use specialized resins with UV inhibitors baked right in, so they stay flexible and strong even after years of punishment.

Saltwater protection is another game-changer. Salt crystals are incredibly destructive, working their way into every crevice and corroding metal parts. True marine zippers use corrosion-resistant materials throughout – often all-plastic construction for sliders, or specially treated metals that laugh at salt spray.

The high-grade components extend to every part of the zipper. The tape won’t fray or tear easily, the teeth maintain their shape under stress, and the slider keeps operating smoothly even after thousands of cycles. It’s the difference between a zipper that lasts a season and one that’s still going strong after a decade.

Want to learn more about what makes our marine zippers special? Our detailed guide on marine zipper features covers all the technical specifications that matter.

How to Select the Perfect Marine Zippers

Choosing the right marine zipper doesn’t have to be overwhelming. Like buying the right anchor for your boat, getting it wrong can cause problems when you least expect them. Your marine environment is tough on equipment, and zippers need to handle sun, salt, and constant moisture that destroy ordinary fasteners. The right marine zipper, however, can last for years with proper care, and understanding the basics makes selection straightforward.

Determining the Right Zipper Size

Here’s where many people get stuck – zipper sizing. We see it all the time: customers bringing in failed zippers that were simply too small for the job. It’s like using a garden hose when you need a fire hose.

Marine zippers are sized by numbers, and the three you’ll encounter most are #5, #8, and #10. The bigger the number, the beefier the zipper. For measuring an existing zipper, look for stamps on metal parts or measure the width of the closed teeth – that’s your most reliable method.

#5 zippers are the lightweight option. While some large manufacturers use them for basic applications, we rarely recommend them for serious marine use. They’re fine for small gear bags or light-duty accessories, but they struggle under real marine stress.

#8 zippers hit the sweet spot for many factory-made boat covers. Production manufacturers love them because they balance cost and performance reasonably well. They’ll do the job, but when durability matters most, bigger is always better.

#10 zippers are our go-to recommendation, and here’s why: they’re built like tanks. The larger teeth and more robust components handle the punishment that marine environments dish out.

Whether you’re covering a 30-foot boat or building a custom bimini top, #10 zippers give you the strength and longevity that make sense financially. We’ve even developed a #12 separating zipper for those who want maximum heavy-duty performance.

For detailed guidance on measuring and identifying the right size for your specific project, check out A guide to zipper sizes.

Material Matters: Plastic vs. Metal Sliders

The slider is where the magic happens – it’s the part that actually opens and closes your zipper. Choose wrong here, and even the best zipper teeth won’t save you. The big decision? Plastic or metal sliders.

Plastic sliders shine in saltwater because they simply don’t care about corrosion. Salt spray, constant moisture, direct saltwater contact – plastic sliders keep working. The downside? They can fatigue over time, especially under stress. We’ve seen plastic sliders on bimini tops lose their grip on the teeth, leading to zippers that won’t stay closed. If you go plastic, plan on potential annual replacements in high-stress areas.

Metal sliders bring serious strength to the table. They grip teeth better and resist breaking under pressure. In freshwater environments, they’re often the superior choice. But saltwater changes everything – metal sliders can corrode and seize up without regular maintenance. The solution? Fresh water rinses and regular lubrication with salt-fighting products.

Stainless steel sliders offer the best of both worlds for metal options. They resist corrosion much better than standard metals while maintaining that superior strength. They’re our premium choice for customers who want maximum durability and don’t mind staying on top of maintenance.

Your choice comes down to your specific situation and maintenance commitment. Saltwater boaters who want low maintenance often prefer plastic sliders despite their eventual fatigue. Serious mariners who prioritize strength and don’t mind regular upkeep often choose stainless steel sliders for their superior holding power and longevity.

Common Zipper Problems and DIY Repairs

Even the highest quality marine zippers can encounter issues. Fortunately, many common problems have simple DIY fixes, saving you the cost of a full replacement. Proactive repairs and understanding common failure points can significantly extend the life of your marine canvas.

Think of it this way: many boat owners spend hundreds on professional zipper replacements when a $5 slider and ten minutes of work would have solved the problem. The key is catching issues early and having the right tools on hand.

Troubleshooting Your Marine Zippers

When your zipper starts acting up, it’s usually trying to tell you something specific. Stuck zippers are often the first sign of trouble, typically caused by salt corrosion, dirt, or debris buildup that makes the slider stiff and stubborn. You’ll know this is happening when what used to glide smoothly now feels like you’re fighting against sandpaper.

Separated teeth present a different challenge entirely. Your zipper might close, but the teeth don’t stay locked together, or they pull apart right after being zipped. This frustrating problem usually stems from a weakened slider that no longer applies enough pressure to keep the teeth engaged, or from UV damage that’s made the teeth themselves chalky and brittle.

Broken sliders are perhaps the most obvious failure mode. The pull tab might snap off during a particularly stubborn opening, or the entire slider body can crack and deform – especially common with plastic sliders that have reached their fatigue limit after countless open-and-close cycles.

Sometimes you’ll find missing zipper stops, which is like having a car without brakes. When a top or bottom stop breaks or falls off, the slider can run right off the end of the zipper tape, leaving you holding a loose slider and staring at a completely non-functional zipper.

The root causes behind these failures tell a story of marine life. Salt buildup is the primary villain for metal slider problems, creating that grinding, stuck feeling. UV degradation works more slowly but just as destructively, breaking down plastic components until they become brittle and chalky. Canvas shrinkage—particularly common with marine fabrics like Sunbrella—puts enormous strain on zippers over time, eventually causing teeth separation or complete slider failure.

Simple Fixes for Pesky Zipper Issues

Don’t panic when your marine zipper starts misbehaving! Many problems have straightforward solutions that don’t require professional help or expensive replacements.

Replacing a slider is probably the most valuable skill any boat owner can learn. If your slider is broken or no longer gripping the teeth properly, a new slider often brings the whole zipper back to life. You’ll need a replacement slider of the correct size, scissors, and needle-nose pliers for this repair.

Start by carefully cutting the zipper tape just below the last tooth on the separating side – make this cut small, just enough to free the old slider. Slide off the broken slider, then slide on the new one in exactly the same orientation. Once your new slider is in position, you’ll need to prevent it from escaping by crimping a new stainless steel zipper stop above your cut, securing it tightly to the last tooth.

Here’s a quick tip that’s saved many a boating trip: if only the pull tab breaks but the slider body is still intact, you can temporarily attach a piece of cord, a large paperclip, or even a stainless-steel split key ring to keep operating the zipper until you can make a proper repair.

Installing a new zipper stop is even simpler. When your slider has fallen off because a stop failed, just crimp a new stainless steel stop onto the last tooth where the slider should live. Make sure it’s secure – this little component prevents much bigger headaches.

Dealing with separated teeth requires some detective work first. Inspect the teeth closely for extreme degradation – if they’re very chalky or crumbling, the entire zipper likely needs replacement. But if the teeth look reasonable, the problem is probably a weakened slider. Try replacing a plastic slider with a metal one of the correct size, as metal sliders often exert more pressure and can re-engage stubborn teeth.

Canvas shrinkage creates unique challenges that standard repairs can’t always address. When Sunbrella and other marine fabrics shrink over time, they put constant strain on zippers, leading to premature failure. We’ve developed specialty zippers specifically designed to accommodate this shrinkage, acting as “spacer zippers” that relieve tension and prevent the zipper from being constantly stressed. These innovative solutions for zipper strain can be a game-changer for extending zipper life.

Lubrication techniques vary depending on what’s causing the stiffness. For salt corrosion on metal sliders, spray generously with penetrating oil and let it sit for 5-15 minutes before gently working the slider. A little heat from a

hair dryer can help loosen stubborn corrosion, and white vinegar works surprisingly well for dissolving salt buildup. Once you’ve cleaned away the corrosion, apply a proper zipper lubricant to keep things moving smoothly.

The satisfaction of bringing a “dead” zipper back to life with a simple repair is something every boat owner should experience. These fixes not only save money but also give you the confidence to handle future problems before they become major headaches.

How do you stop a zipper from opening on its own?

Nothing’s more frustrating than a marine zipper that won’t stay closed, especially when you’re trying to keep the elements out of your boat. The good news is there are several proven solutions.

Locking sliders are your best friend here. These clever devices have a small spring-loaded mechanism that grabs the teeth when you release the pull tab. The zipper stays put until you actively pull the tab again. If your current zipper doesn’t have this feature, replacing the slider with a locking version often solves the problem completely.

For vertical applications like enclosure panels, double-pull sliders give you control from both ends and typically include locking features. This prevents the zipper from creeping open due to wind pressure or vibration.

Sometimes the issue is simply a worn-out slider that no longer applies enough pressure to keep the teeth engaged. A fresh slider of the correct size can work wonders, especially if you upgrade from plastic to metal for better gripping power.

But here’s the real culprit we see most often: canvas shrinkage putting excessive tension on the zipper. Marine fabrics naturally shrink over time, stretching zippers tight and forcing them to separate under strain. We’ve developed specialty zippers specifically to address this common problem, acting as tension relievers that accommodate shrinkage without compromising the closure. Check out our Solutions for zipper strain to see how these innovative designs can save your sanity.

What is the best way to lubricate a plastic zipper?

Lubricating plastic zippers properly can mean the difference between smooth operation and a frustrating wrestling match every time you need to zip up your boat cover.

Silicone-based sprays and wax sticks are your go-to choices for plastic zippers. Silicone creates a slick surface that reduces friction without harming the plastic components. Wax sticks are particularly effective because they create a protective barrier that repels salt and grime while providing smooth operation.

Here’s what to avoid: petroleum-based lubricants. These products might seem like they’d work great, but they can actually make plastic components brittle over time. They also act like magnets for dirt and sand, turning your smooth zipper into a gritty mess.

The application technique matters too. After cleaning your zipper thoroughly with fresh water, apply the lubricant sparingly directly to the teeth and inside the slider channels. Then comes the important part: work the slider back and forth along the entire zipper length several times. This distributes the lubricant evenly and ensures every tooth gets proper coverage.

A little goes a long way. Over-lubricating just creates a sticky trap for debris, which defeats the whole purpose of maintenance.

Conclusion

Understanding marine zippers doesn’t have to be overwhelming – it’s really about making smart choices and taking care of what you’ve got. We’ve walked through everything from the nitty-gritty of coil versus molded tooth designs to the specialized features that make a zipper truly “marine grade.” You now know how UV resistance and corrosion protection can save you headaches down the road, and you’ve got the knowledge to pick the right size and slider material for your specific setup.

The DIY repair techniques we shared can rescue you from many common zipper mishaps, while our maintenance tips will help your zippers weather countless seasons on the water. Regular cleaning with fresh water, proper lubrication, and annual inspections – these simple steps make all the difference between zippers that last and ones that leave you stranded with a broken boat cover.

Investing in quality marine zippers and maintaining them properly isn’t just about saving money on replacements. It’s about peace of mind when you’re out on the water, knowing your bimini top won’t fail in a sudden squall or your boat cover won’t come loose during storage. The right zipper choice today prevents those frustrating moments tomorrow.

Here at Lenzip, we’ve been perfecting zippers for 80 years, and we understand what the marine environment demands. We manufacture every zipper right here in Rolling Meadows, Illinois, bringing American craftsmanship to every product that leaves our facility. Our commitment goes beyond just making zippers – we’re dedicated to unparalleled quality, integrity, and getting your order to you on time, every time.

That’s why Lenzip zippers come with a lifetime warranty for the life of your canvas. When you choose Lenzip, you’re not just buying a zipper – you’re investing in a product engineered to handle whatever the sea throws at it. We stand behind our work because we know it can take the punishment.

Ready to upgrade your marine equipment with zippers that won’t let you down?

Explore our full range of specialty zippers and find why boat builders and canvas professionals trust Lenzip to keep their projects secure, season after season.

Your Partner in Production

We understand that every project is unique, which is why we offer the flexibility you need. Our B2B focus means we can support your business with options that work for you, including minimums as low as 25 units. We are not just a supplier; we are your partner, committed to helping you find the right solution to fit your specific requirements.

Let’s Find the Right Solution for You

Ready to upgrade to the Lenzip standard? We’re here to help.

Talk to a representative today. We’ll help you find the right solution for your project

Call us at (847) 368-9000 or request a quote today.