Nylon vs polypropylene: discover key differences in properties, applications, and cost. Choose the right material for your project.

Nylon vs polypropylene represents one of the most critical material choices facing manufacturers today. Both synthetic thermoplastics offer distinct advantages, but choosing the wrong one can lead to product failures, increased costs, and disappointed customers.

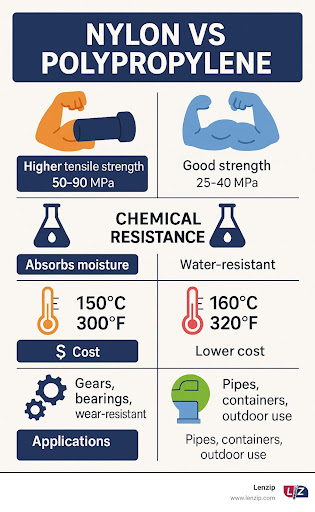

Quick Comparison:

Factor | Nylon | Polypropylene |

Strength | Higher tensile strength (50-90 MPa) | Good strength (25-40 MPa) |

Cost | More expensive | More affordable |

Moisture | Absorbs water (0.3-7%) | Water-resistant (0.01%) |

Heat Resistance | Better (150°C/300°F) | Good (160°C/320°F) |

Flexibility | More elastic and flexible | More rigid, shape-retaining |

Best For | High-stress, wear-resistant applications | Chemical resistance, outdoor use |

As one industry expert noted: “Polypropylene is sometimes referred to as the ‘steel of plastics’ due to its high strength,” while nylon earns praise as “a low-friction plastic, which makes it ideal for creating parts used in high-friction industrial applications.”

The choice between these materials affects everything from product durability to manufacturing costs. Nylon excels in applications requiring exceptional strength, flexibility, and abrasion resistance – think gears, bearings, and high-performance textiles. Polypropylene shines where chemical resistance, moisture barriers, and cost-effectiveness matter most – like packaging, automotive components, and outdoor applications.

Understanding these fundamental differences helps manufacturers avoid costly mistakes and select the optimal material for their specific requirements.

At the Core: Chemical and Structural Differences

The different feel of a nylon zipper versus a polypropylene container comes from their molecular makeup. The nylon vs polypropylene comparison is a look at two distinct chemical families that are both classified as plastics.

What is Nylon?

Nylon is a polyamide, a family of polymers known for incredible strength. Developed by DuPont in 1935, it was a synthetic material.

Nylon is formed through condensation polymerization, where two different molecules—a diamine and a dicarboxylic acid—join together, releasing a water molecule in the process. This reaction creates strong amide bonds that link the polymer chains.

These bonds enable powerful hydrogen bonding between the chains, giving nylon its impressive high tensile strength and ability to withstand significant pulling forces.

Furthermore, nylon’s crystalline structure and molecular weight contribute to a material that is both highly durable and remarkably elastic. It can be stretched and bent while retaining its shape. Its naturally low friction properties make it ideal for moving parts and high-wear applications.

What is Polypropylene?

Polypropylene, a polyolefin developed in 1954, is created through a simpler process. It uses addition polymerization, where propylene monomer units are added to one another in a chain without creating byproducts.

This straightforward chain-building process results in a remarkably lightweight material, perfect for applications requiring strength without bulk. Its molecular structure also provides excellent chemical resistance, making it nearly immune to most acids, bases, and solvents.

Crucially for many uses, polypropylene is an outstanding moisture barrier. While nylon absorbs water, which can alter its properties, polypropylene repels moisture. Its natural rigidity also means it holds its shape well under stress.

This polymerization process and structure explain why polypropylene excels in packaging, outdoor products, and applications requiring reliable performance in harsh chemical environments. It is engineered to be a reliable and cost-effective solution for specific jobs.

Understanding these fundamental differences in chemical structure explains their different behaviors in real-world applications and why the nylon vs polypropylene choice is so critical in manufacturing.

A Head-to-Head Comparison: Nylon vs Polypropylene Properties

Let’s put nylon vs polypropylene head-to-head to see how their properties stack up in real-world applications.

Mechanical and Physical Properties

When it comes to raw strength, nylon has the advantage. With a tensile strength of 50-90 MPa compared to polypropylene’s 25-40 MPa, nylon handles significantly more pulling force. This strength comes from its strong amide and hydrogen bonds.

However, polypropylene is significantly lighter. At just 0.904-0.908 g/cm³, it’s a clear choice over nylon (1.13-1.15 g/cm³) when reducing weight is a priority, as the savings add up quickly in large-scale production.

Both materials are durable, but in different ways. Nylon excels in high-abrasion situations due to its low friction coefficient, which makes it almost self-lubricating and ideal for moving parts.

Polypropylene is less flexible than nylon but can bend without cracking and holds its shape well. Its greatest advantage is moisture resistance. While nylon can absorb up to 7.0% of its weight in water (affecting its stability), polypropylene absorbs a mere 0.01%, making it an excellent moisture barrier.

Property | Nylon | Polypropylene |

Tensile Strength | Excellent (50-90 MPa) | Good (25-40 MPa) |

Durability | Exceptional, resists wear & tear | Very good, known for toughness |

Abrasion Resistance | Excellent, best in high-abrasion | Good, but not as superior as nylon |

Flexibility & Elasticity | High, recovers shape after stretching | Less flexible, but can bend without cracking |

Weight & Density | Heavier (1.13-1.15 g/cm³) | Lightweight (0.904-0.908 g/cm³) |

Friction Coefficient | Low, self-lubricating | Higher |

Moisture Absorption | High (0.30-7.0% by weight), can affect stability | Very low (0.01% after 24h), excellent moisture barrier |

Resistance to Environmental Factors

Understanding how these materials react to environmental factors is critical for product success.

Heat resistance is complex. Nylon generally handles continuous use temperatures around 150°C (300°F), with melting points from 220°C to 260°C depending on the type. Polypropylene melts around 160°C (320°F) but often performs better in certain high-temperature applications due to its superior heat deflection properties.

For chemical resistance, polypropylene is the clear winner. It is highly resistant to acids, bases, and organic solvents. Nylon is tough against oils and gasoline but is vulnerable to strong acids and bases.

Regarding UV resistance, both materials require help. Polypropylene is vulnerable to UV degradation and needs additives to prevent it from becoming brittle. Nylon has better natural UV resistance but also benefits from stabilizers for long-term outdoor use.

In cold weather, polypropylene can become brittle, while nylon maintains its flexibility and resilience, making it a better choice for applications with wide temperature swings.

For those working with specialized applications like webbing, you can find more info about webbing materials to understand how these properties translate into real-world performance.

Understanding these environmental factors is the difference between a product that lasts and one that fails.

Common Applications: Where Each Material Shines

Understanding the properties of nylon vs polypropylene helps clarify where each material excels in the real world.

This section details the most suitable uses for each material based on their inherent properties.

Key Applications for Nylon

Nylon’s high tensile strength and exceptional abrasion resistance make it ideal for demanding applications.

- High-stress applications: Nylon’s ability to withstand enormous pulling forces makes it essential for heavy-duty ropes, fishing nets, and industrial strapping.

- Engineering components: Its low friction properties mean nylon gears and bearings run smoothly with minimal wear. It’s even used to replace some aluminum engine components due to its strength and insulation properties.

- Textiles & apparel: The industry relies on nylon for its elasticity and durability in activewear, hosiery, and carpeting.

- Ropes & webbing: High abrasion resistance makes nylon the standard for safety-critical items like military equipment, climbing harnesses, and safety belts. Its ability to bend without breaking offers great design flexibility.

- High-abrasion uses: Nylon is often the only choice for items like toothbrush bristles and zipper components. For more on zipper parts, see our guide on Zipper Terminology.

- Sports equipment: Manufacturers use nylon for strong fishing lines, durable tennis racket strings, and lightweight, weather-resistant tent fabrics.

Key Applications for Polypropylene

Polypropylene is the solution where chemical resistance and cost-effectiveness are paramount.

- Chemical exposure applications: Its resistance to acids, bases, and solvents makes it the top choice for chemical storage tanks and lab equipment.

- Packaging: The packaging industry uses polypropylene extensively for food containers, bottle caps, and shipping containers due to its excellent moisture barrier properties and affordability.

- Automotive parts: Its great strength-to-weight ratio makes it perfect for car bumpers, dashboards, and interior panels, helping to improve fuel efficiency.

- Medical applications: Polypropylene can be sterilized and is chemically resistant, making it ideal for disposable syringes and petri dishes.

- Hinges and moving parts: Its fatigue resistance allows for the creation of “living hinges”—thin sections of plastic that bend repeatedly without failing, used in items like toolbox lids and bottle caps.

- Outdoor furniture: With UV stabilizers, polypropylene resists mold, moisture, and temperature swings, making it perfect for patio furniture.

- Moisture-wicking fabrics: Its hydrophobic nature makes it excellent for athletic wear and stain-resistant carpeting.

Understanding these applications shows that the nylon vs polypropylene debate isn’t about which is better, but which is the right tool for the job.

Practical Considerations: Manufacturing, Cost, and Sustainability

When you’re choosing between nylon vs polypropylene, the technical specs are just part of the story. The real-world factors – how they’re made, what they cost, and their environmental footprint – often make or break a project decision.

Key Differences in Nylon vs Polypropylene Manufacturing

Here’s where things get interesting from a production standpoint. Both materials are thermoplastics, which means they can be melted down and reshaped over and over again. This makes them perfect for common manufacturing processes like injection molding and extrusion.

But that’s where the similarities end. Polypropylene pellets have lower melt viscosity than nylon, which is manufacturing speak for “PP flows like honey while nylon flows more like thick syrup.” This difference is huge for production teams because lower viscosity means polypropylene is easier and faster to process. It flows readily into complex mold shapes and fills thin sections without much fuss.

Nylon, on the other hand, requires higher processing temperatures and longer cooling times. Think of it like baking – nylon needs more heat to get going and takes longer to set properly. This translates directly to higher energy costs and longer production cycles.

Here’s where nylon gets its revenge though – it’s more malleable than polypropylene and offers product teams greater design flexibility. Need to paint it? Bond it to another material? Add special finishes? Nylon plays well with others and offers more finishing and post-production options thanks to its surface texture.

Polypropylene? Well, it’s famously stubborn when it comes to surface treatments. It’s nearly impossible to paint due to its slippery surface, and bonding it to other materials can be a real headache. But hey, sometimes being low-maintenance is exactly what you want.

Cost-Effectiveness and Availability

Let’s talk money – because at the end of the day, budgets matter. Polypropylene is more affordable than nylon, and we’re not talking about pocket change here. Polypropylene averages around $1.3 per kilogram while nylon runs about $2.4 per kilogram. That’s nearly double the material cost right off the bat.

The cost advantages of polypropylene don’t stop at raw materials either. Remember how it’s easier and faster to process? That translates to lower manufacturing costs through reduced cycle times and less energy consumption during production. Your production line can churn out more parts in less time with lower utility bills.

But here’s the thing about cost – sometimes spending more upfront saves you money down the road. Nylon’s superior durability and performance can mean fewer product failures, less warranty claims, and happier customers. It’s all about finding that sweet spot between performance value and budget constraints.

Both materials enjoy good market availability since they’re produced globally, though specific grades and regional factors can sometimes throw curveballs into supply chain planning.

Environmental Impact of Nylon vs Polypropylene

Sustainability isn’t just good PR anymore – it’s becoming a make-or-break factor for many companies and consumers. So how do these materials stack up environmentally?

The production story isn’t great for either material, honestly. Both require significant energy to produce, which means greenhouse gas emissions. But nylon production is even more energy-intensive than polypropylene, leading to a larger carbon footprint from day one.

When it comes to recyclability, polypropylene takes the lead. It’s coded as #5 in recycling systems and can save around 88% less energy than virgin material when recycled. The catch? Recycling infrastructure varies wildly depending on where you are. Some places have great PP recycling programs, others… not so much.

Nylon recycling is trickier. Different types of nylon and blends with other materials make it not as easily recyclable as polypropylene. While it’s technically possible to recycle nylon, the process is more complex and less widely available.

Neither material wins any awards for biodegradability. Polypropylene takes 20-30 years to break down in landfills, while nylon doesn’t readily biodegrade at all, creating longer-term environmental concerns. For products designed to last decades, this might not be a dealbreaker. For single-use items? It’s definitely something to consider.

The most sustainable approach with both materials involves reducing consumption, reusing products whenever possible, and choosing items made with recycled content when available. For specialized applications requiring strict environmental and performance standards, resources like information on mil-spec webbing standards can provide valuable guidance on balancing sustainability with performance requirements.

Frequently Asked Questions about Nylon and Polypropylene

When helping customers choose the right material for their projects, we get asked the same questions time and again about nylon vs polypropylene. Let’s clear up the most common confusion points with straightforward answers.

Which material is stronger, nylon or polypropylene?

Here’s where things get interesting – “stronger” means different things depending on what you’re trying to accomplish!

When we talk about tensile strength (how much pulling force a material can handle before breaking), nylon is the clear winner with 50-90 MPa compared to polypropylene’s 25-40 MPa. Those strong hydrogen bonds between nylon’s polymer chains give it that extra muscle for applications where something’s constantly being tugged or stretched.

Durability and abrasion resistance is another area where nylon shines. It handles friction and wear like a champ, making it perfect for parts that get rubbed, scraped, or abraded regularly. Polypropylene holds its own with good abrasion resistance, but it can’t quite match nylon’s performance here.

For impact strength, nylon’s natural elasticity helps it absorb shocks without cracking. It bends instead of breaking, which is exactly what you want in high-stress situations. Polypropylene is tough in its own right and can deform without breaking, but it gets brittle when temperatures drop.

That said, polypropylene earns its nickname as the “steel of plastics” for good reason. It offers excellent overall resistance to physical stress and stands up beautifully to environmental challenges like sun, moisture, and chemical exposure.

The bottom line? For high-tension, high-wear applications, nylon typically wins. For situations where you need lightweight strength, chemical resistance, and cost-effectiveness, polypropylene might be your hero.

Is nylon or polypropylene better for outdoor use?

Outdoor applications throw some serious challenges at materials – blazing sun, driving rain, temperature swings, and everything Mother Nature can dish out.

Let’s start with UV resistance. Both materials need some help here. Polypropylene is susceptible to UV degradation and requires additives for outdoor use to prevent it from getting brittle and faded. Nylon handles UV exposure better naturally, but it still benefits from UV stabilizers for long-term outdoor performance.

Moisture absorption is where polypropylene really shows its outdoor chops. It has excellent moisture barrier properties and absorbs very little water (just 0.01% after 24 hours). Nylon, on the other hand, can absorb significant moisture – anywhere from 0.3% to 7% by weight – which can change its dimensions and stability. That’s not ideal for outdoor gear that needs to maintain its shape and performance in wet conditions.

When it comes to temperature fluctuations, each material has its strengths. Nylon stays more flexible when temperatures drop, while polypropylene can become brittle in extreme cold. However, polypropylene handles heat and intense sun exposure exceptionally well.

For most outdoor applications, polypropylene often takes the lead – especially when it’s properly formulated with UV stabilizers. Its natural resistance to moisture and chemicals makes it incredibly robust against weather. But if you’re dealing with extreme cold where flexibility matters, nylon might be the smarter choice.

Which material is more expensive?

This one’s pretty straightforward, and it often becomes the deciding factor for many projects.

Polypropylene is more affordable than nylon – significantly so. Our research shows polypropylene averaging around $1.3 per kilogram while nylon runs about $2.4 per kilogram. That’s nearly double the cost for raw materials alone.

Manufacturing complexity adds to the cost difference. Polypropylene processes easier and faster, with lower melt viscosity and shorter cooling times. This translates to lower energy costs and faster production cycles. Nylon requires higher processing temperatures and longer cooling times, which adds up in manufacturing expenses.

For large-volume production, these cost differences become substantial. If you’re making thousands or millions of parts, choosing polypropylene over nylon can significantly impact your bottom line.

But here’s the important caveat: performance value matters too. While nylon costs more upfront, its superior tensile strength, abrasion resistance, and durability can provide better long-term value. Sometimes spending more initially saves money down the road through fewer replacements and longer product life.

The key is matching your material choice to your specific needs and budget. For cost-sensitive applications where polypropylene’s properties meet your requirements, it’s hard to beat. For demanding applications where nylon’s superior performance is essential, the extra cost often pays for itself.

Conclusion: Making the Right Choice for Your Project

Choosing between nylon vs polypropylene is like picking the right teammate for your project – each brings unique strengths to the table, and the best choice depends entirely on what challenges you’re facing.

Throughout our deep dive, we’ve finded that nylon is your go-to when you need a material that can take a beating and keep on performing. Its exceptional tensile strength, impressive elasticity, and superior abrasion resistance make it the champion for high-stress situations. Whether you’re designing engineering components that need to move smoothly for years, creating textiles that must stretch and bounce back, or building equipment that faces constant friction, nylon rises to the challenge.

Polypropylene tells a different success story. It’s the practical problem-solver that excels where chemical resistance, moisture protection, and cost-effectiveness matter most. Its lightweight nature doesn’t compromise its strength, and its ability to shrug off harsh chemicals while maintaining structural integrity makes it invaluable for packaging, automotive applications, and outdoor products.

The magic happens when you match these material personalities to your specific needs. Are you dealing with extreme pulling forces or components that rub against each other constantly? Nylon’s your answer. Need something that won’t flinch when exposed to harsh chemicals or won’t absorb moisture in damp environments? Polypropylene steps up to the plate.

Cost considerations play a real role too. While polypropylene typically offers better upfront affordability and easier processing, nylon’s superior durability in demanding applications can deliver better long-term value through reduced replacements and improved product lifespan.

At Lenzip, our 80 years of manufacturing high-quality, custom commercial and industrial zippers has taught us that material selection isn’t just about specs on a datasheet – it’s about understanding how those properties translate into real-world performance. Our commitment to unparalleled quality, integrity, and reliable on-time delivery stems from making these precise material choices every day.

The environmental impact deserves consideration too. Both materials have their challenges and opportunities for sustainability, but understanding their recycling pathways and energy requirements helps you make responsible choices that align with your project’s values.

Success comes from balancing all these factors – performance requirements, cost constraints, environmental responsibility, and manufacturing considerations. By taking the time to understand your application’s unique demands and matching them to the right material’s strengths, you set your project up for long-term success.

Explore our high-quality webbing solutions to see how proper material selection translates into exceptional products that deliver reliable performance when it matters most.