Beyond the Standard:

Getting Your Perfect Custom Zipper

Stop project frustration. Get the perfect fit and professional finish with custom length zippers. Order yours today!

Stop the guesswork and frustration that come with trying to make a standard zipper fit a non-standard project.

For more than eighty years, LenZip Manufacturing has helped designers, engineers, and craftspeople transform ordinary closures into precision-made components that perform flawlessly.

Whether you build marine covers, industrial equipment, or technical apparel, a custom-length zipper is the hidden detail that separates “good enough” from professionally engineered.

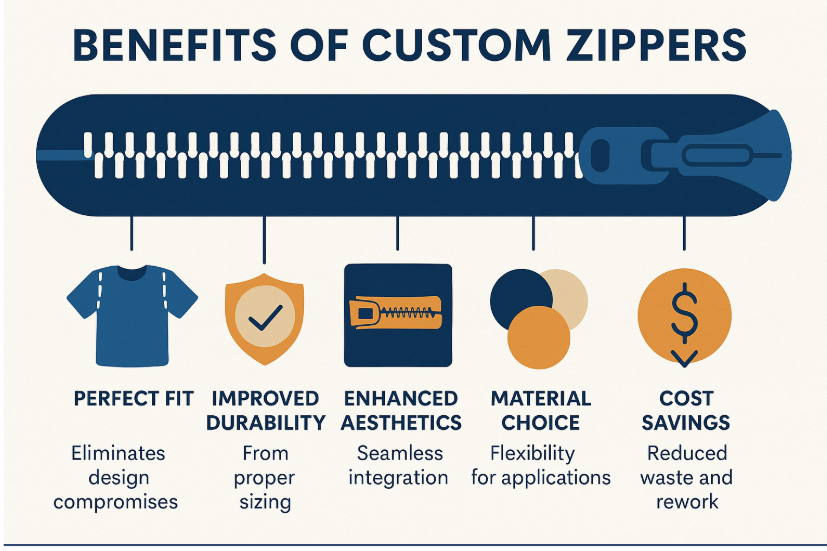

Why Custom Zippers Matter

Every project starts with a vision—clean lines, consistent tension, and components that work together as a system.

Yet one part is almost always overlooked until the final stages: the zipper.

When the available sizes don’t match your pattern, you’re forced to redesign, settle for multiple short sections, or trim an oversized chain that never looks quite right.

Each of those shortcuts compromises strength, symmetry, and aesthetic value.

Custom zippers remove those compromises completely.

They’re built or cut precisely to your measurements, eliminating the slack, bunching, and premature wear that occur when a closure is forced to fit.

Instead of adapting your product to the zipper, the zipper adapts to your product.

At LenZip USA, our engineers manufacture and cut zippers ranging from four inches to well over two hundred inches.

A 27-inch two-way zipper for a protective cover, a 108-inch marine enclosure, or a delicate four-inch closure for a small pouch—all can be specified, produced, and shipped quickly.

Typical turnaround is two to three business days for custom-cut stock and about two weeks for full manufacturing runs.

There are often no minimums for cut-to-length orders, giving small-batch makers and prototype developers the same level of precision as large OEMs.

(See our Custom Fit: Demystifying Cut-to-Length Zippers guide for details.)

The Power of a Perfect Fit

Picture finishing a premium leather duffel, a boat enclosure, or a heavy-duty tent.

Everything is flawless—until the zipper.

Too short, and it refuses to close; too long, and it ripples and folds.

A perfect zipper length changes everything.

It aligns with the design, eliminates stress points, and moves with the fabric instead of fighting against it.

A properly sized zipper does more than improve appearance.

It extends the product’s service life by reducing strain on teeth, sliders, and tape.

A marine cover that’s even half an inch short is under constant tension, leading to early failure.

A precisely fitted zipper, on the other hand, distributes force evenly, maintaining smooth operation for years of daily use.

That’s why LenZip’s U.S.-made custom zippers are trusted across sectors—from small artisan shops to global manufacturers.

Our customers build products for extreme conditions: saltwater exposure, UV radiation, temperature swings, and constant flexing.

We engineer each closure to perform in those environments without corrosion or stiffness.

Read more about our American manufacturing heritage and how local production keeps quality and delivery consistent.

Zipper Gauge and Strength: Understanding the Numbers

When professionals refer to a #3, #5, #8, or #10 zipper, they’re talking about the gauge—the width of the teeth when the chain is closed, measured in millimeters.

Think of it like wire gauge or bolt size: the higher the number, the stronger and heavier the closure.

A #3 zipper (about 3 mm wide) is ideal for lightweight clothing, pockets, and accessories.

#5 zippers (≈ 5 mm) handle jackets, sleeping bags, and medium-duty luggage.

#8 zippers (≈ 8 mm) step up to heavy outerwear and tents.

#10 zippers (≈ 10 mm) dominate marine, industrial, and protective gear where brute strength and longevity matter most.

Choosing the correct gauge prevents failure.

Using a #3 zipper on a tarp is like using sewing thread to lift an engine—it simply isn’t designed for that load.

Likewise, a #10 zipper on a silk dress would feel clumsy and heavy.

Balance is key.

To compare sizes and tensile strengths, consult the LenZip Zipper Gauge & Chain Size Chart.

Applications That Depend on Custom Sizing

The need for perfectly fitted zippers spans far more industries than most people imagine.

In marine fabrication, boat tops and cockpit covers often exceed 100 inches in length and require corrosion-proof hardware plus UV-stable tape.

In camping and outdoor gear, tent doors, sleeping bags, and ventilation panels must align exactly with pre-cut fabric sections.

Leather goods and fashion accessories rely on precise closure placement for symmetry and luxury appeal.

Industrial covers and equipment enclosures need heavy-gauge zippers that maintain airtight or dust-tight seals under stress.

Even upholstery and cushions benefit from exact sizing—no puckering, no excess material, just clean professional seams.

You can explore specific case studies in the LenZip Industries section to see how different markets apply our technology.

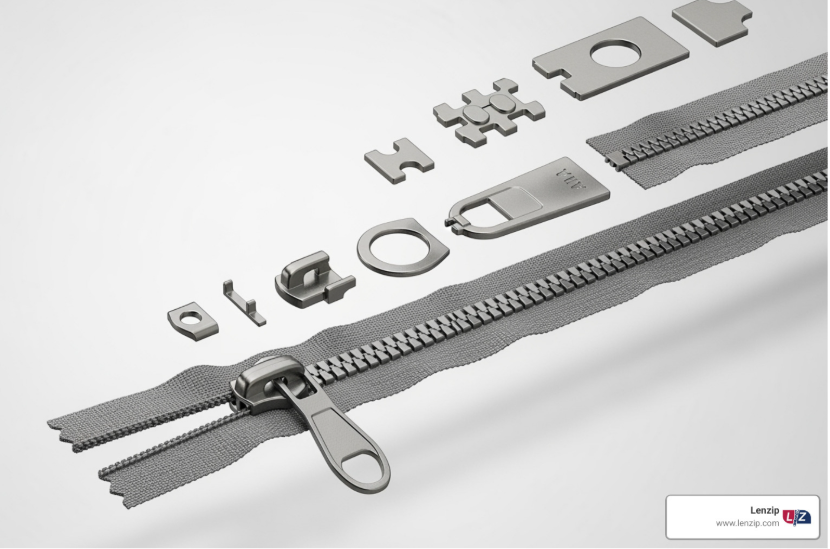

Decoding Your Zipper: Key Components to Customize

A zipper might look simple, but every part contributes to performance.

Each element—tape, teeth, slider, and stops—can be specified to meet your exact requirements.

The tape is the woven foundation that holds the entire assembly.

LenZip offers polyester, nylon, and specialty coated tapes that balance flexibility with tensile strength.

Color customization is virtually unlimited; our dye facilities can match Pantone references so your zipper integrates seamlessly into your product design.

(See Zipper Materials & Finishes for details.)

The teeth, or “elements,” are the interlocking pieces that actually create closure.

They can be metal, molded plastic, or continuous nylon coil—each with its own performance profile, which we’ll explore later.

The slider is the engine of the zipper, converting motion into engagement or release.

Choosing the right slider type—autolock, non-lock, or reversible—affects usability and safety.

For technical insights, visit the Guide to Zipper Teeth, Sliders & Parts.

Finally, the stops are your safety guards.

Top and bottom stops prevent the slider from running off the chain, while insertion pins and boxes allow separating zippers to detach fully.

Each must be sized to your gauge to ensure long-term reliability.

When LenZip builds a custom-length zipper, we don’t simply cut a stock roll; we design an integrated system where these four components work together perfectly.

That’s the same engineering mindset we apply to aerospace, marine, and industrial clients who can’t afford mechanical failure.

Material Matters: Metal, Coil, and Molded Plastic

Different projects demand different personalities of zipper materials.

Metal, coil, and molded plastic each bring their own strengths.

Metal zippers are the classics.

Brass provides timeless durability and resistance to corrosion; nickel and gunmetal finishes offer modern aesthetics; aluminum gives strength without weight.

They’re perfect for leather goods, denim, luggage, and any product that benefits from a premium tactile feel.

The trade-off is flexibility—metal zippers are rigid, making them less suited to curved seams or compressible fabrics.

Nylon coil zippers are the multitaskers.

Made from a continuous nylon filament, they combine light weight, high flexibility, and impressive strength.

They also have a useful self-healing characteristic: if the teeth misalign, running the slider back and forth usually resets the chain.

Coil zippers excel in sleeping bags, technical jackets, and tents—anywhere smooth motion around curves is essential.

Molded plastic zippers are the outdoor champions.

Each tooth is injection-molded directly onto the tape, forming a tough, weather-proof bond.

They shrug off UV light, temperature extremes, and saltwater exposure, making them indispensable in marine and outdoor industries.

To learn more about their protective coatings, visit Zipper Coatings & Finishes.

The choice often comes down to environment and flexibility:

Metal for aesthetic strength and heritage style.

Coil for versatility and curves.

Molded plastic for weather and chemical resistance.

Understanding Gauge and Strength

When engineers talk about zipper gauge, they’re really talking about mechanical performance. The gauge determines how much stress the chain can handle before deformation occurs and how smoothly the slider tracks under load. A properly matched gauge resists both torsion and lateral tension—the two primary forces that cause premature failure.

LenZip’s quality-control testing follows strict ASTM D2061 and ISO standard pull-strength protocols, ensuring every chain performs beyond its rated load. That’s one reason our #8 and #10 marine and industrial zippers outperform many imported versions by as much as 20 percent in tensile and fatigue testing. You can learn more about our validation process in the Zipper Testing Standards guide.

Matching gauge to use case is straightforward once you understand the principles.

A #3 zipper may be small, but it offers excellent flexibility for garments and accessories. Mid-range gauges (#5–#7) provide balanced strength for luggage, upholstery, and outerwear. Heavy-duty #8–#10 chains are engineered for environments where grit, pressure, or vibration are constants. The rule of thumb: the heavier the load, the higher the gauge.

Choosing Your Zipper’s Function: End Types and Sliders

Function defines usability. A zipper that opens the wrong way—or not far enough—can ruin a carefully engineered product.

Closed-end zippers stay permanently joined at the bottom and are ideal for pockets, handbags, and upholstery cushions. They offer stability and quick operation where full separation isn’t needed.

Separating zippers completely detach using an insertion pin and retainer box. These are essential for jackets, removable panels, or modular equipment covers that need full access.

Two-way zippers incorporate dual sliders that allow opening from either direction. They’re invaluable for long coats, sleeping bags, or industrial enclosures where flexible access or ventilation is required.

Then comes slider type. Autolock sliders engage a locking mechanism whenever the pull tab lies flat—perfect for garments or safety gear that must stay closed under tension. Non-locking sliders glide freely, favoring bags or pouches where speed matters more than security. Reversible sliders offer dual-side operation for items like reversible jackets or double-sided covers.

For a detailed comparison of these mechanical differences, visit Zipper Types Explained.

Step 1: Measuring for a Custom Zipper

Measurement errors are the most common reason projects fail inspection. Always measure only the interlocking teeth length—not the fabric extensions.

For separating zippers, measure from the top of the teeth to the bottom of the insertion pin.

For closed-end zippers, measure from the top teeth edge to the bottom stop.

Keep the zipper completely closed during measurement, and double-check using a flat surface to avoid curvature distortion.

If you’re unsure, our Zipper Gauge Chart shows exact chain widths and recommended tolerances. Remember: even one-eighth of an inch off can compromise alignment in precision manufacturing.

Step 2: Selecting Materials and Components

This is where creativity meets engineering. Selecting materials isn’t only about aesthetics; it’s about performance synergy between tape, teeth, slider, and pull.

Tape Material and Color

Most industrial and apparel projects rely on polyester tape for its strength and UV stability. For weldable assemblies, TPU and PU-coated tapes integrate seamlessly with vinyl and poly fabrics. LenZip can match nearly any Pantone color using proprietary dyes, ensuring branding consistency. (Explore color and coating options in Zipper Materials & Finishes.)

Slider and Pull Style

Autolock sliders are standard for garments, while non-locking or double sliders fit luggage and industrial products. Pull tabs may be minimalistic for fashion or oversized for gloved operation. Many OEMs commission custom logo pulls, enhancing both ergonomics and branding.

Teeth Material and Gauge

Match the chain to the expected environment—metal for abrasion resistance, molded plastic for weather protection, and nylon coil for flexibility. For cross-reference, see our Guide to Zipper Teeth, Sliders & Parts.

Step 3: Ordering Your Custom Zippers

Once specifications are ready—length, gauge, material, slider type, color, and quantity—you’re prepared to order.

LenZip’s Request a Quote system streamlines the process for both prototype and large-volume production.

Turnaround Times

Custom-cut zippers from existing stock ship in two to three business days. Fully manufactured, made-to-order zippers require about two weeks depending on materials and finishes.

Minimum Orders

There’s often no minimum for custom-cut stock items, ideal for one-off prototypes. Fully bespoke manufacturing—custom dyes, unique hardware, or specialty coatings—typically begins around 100 pieces.

Domestic Manufacturing Advantage

Every zipper is produced in Rolling Meadows, Illinois, under LenZip’s tight quality control. Domestic manufacturing ensures supply-chain stability, rapid shipping, and consistent tensile strength verification. Learn why U.S. production matters in Why U.S. Zipper Manufacturing Matters for Supply Chain Stability.

Beyond Ordering: Quality and Testing

LenZip’s commitment to quality doesn’t end at shipment. Each production run undergoes slider fatigue, chain tensile, and corrosion testing following How Zippers Are Tested for Strength, Corrosion, and Fatigue. Our marine and outdoor clients depend on this reliability because failure in the field costs time, money, and reputation.

For clients in aerospace, industrial containment, and tactical markets, we also provide custom documentation packages referencing ASTM, MIL-SPEC, and ISO compliance data. This transparency builds trust and simplifies certification audits.

Conclusion: Lift Your Project with the Perfect Fit

Every stitch, seam, and component tells a story about the maker. The zipper may be small, but it carries the reputation of your craftsmanship.

By choosing LenZip’s custom-length zippers, you eliminate compromise: no uneven stress, no improvised fixes, no inconsistent quality.

Whether your product shields equipment from salt spray, defines a luxury handbag, or seals industrial containment fabric, a precision-engineered zipper elevates it from acceptable to exceptional.

Our team in Rolling Meadows, Illinois stands behind every chain, slider, and tape we produce. After eight decades, we still believe that details matter—and that American manufacturing can deliver both quality and reliability.

Ready to experience the difference?

Explore Custom Zipper Products or Request a Quote to start your next project today.

FAQ — Custom Zippers

Can I turn a continuous chain into a separating zipper?

No. Continuous chain lacks the insertion pin and retainer box that let both sides detach. Attempting to modify it compromises integrity. Order true separating zippers instead.

What’s the difference between custom-cut and custom-manufactured?

Custom-cut zippers are trimmed from LenZip’s stocked chains and sliders, tailored to your specified length—fast, affordable, and flexible.

Custom-manufactured zippers start from raw materials and include unique tape colors, finishes, or branded components. This route takes longer but yields total design control.

Do you offer waterproof or flame-resistant zippers?

Yes. We engineer marine, FR, airtight, and RF-weldable zippers for harsh environments. Learn more under Industrial Curtain Zippers and Fire-Resistant Zippers: Engineering Safety.

What’s your turnaround time?

Cut-to-length orders ship within three days; fully custom production averages two weeks. Expedited manufacturing may be available for urgent projects—contact Request a Quote.

Is there a minimum order?

Not for cut-to-length stock. Fully custom manufacturing begins near 100 units, depending on materials and finish complexity.

How do I choose the right gauge?

Consult our Zipper Gauge Chart to match chain width to fabric stress. For marine or industrial covers, #8 or #10 is typically recommended.

Can I order custom colors or logo pulls?

Absolutely. LenZip provides full Pantone matching and custom-molded pulls through our Materials & Finishes Program.

What are the benefits of domestic manufacturing?

U.S. production guarantees shorter lead times, stable supply, and ethical labor practices—plus the advantage of direct collaboration with engineers who understand your specifications.

How should I measure for a custom zipper?

Always measure with the zipper closed, from top stop to bottom stop or box. Exclude the extra tape length. Double-check measurements twice before ordering.

Can LenZip help with prototyping and testing?

Yes. We frequently partner with product developers to prototype zippers for new designs, offering short-run sampling and performance testing before full production.

Your Partner in Production

We understand that every project is unique, which is why we offer the flexibility you need. Our B2B focus means we can support your business with options that work for you, including minimums as low as 25 units. We are not just a supplier; we are your partner, committed to helping you find the right solution to fit your specific requirements.

Let’s Find the Right Solution for You

Ready to upgrade to the Lenzip standard? We’re here to help.

Talk to a representative today. We’ll help you find the right solution for your project

Call us at (847) 368-9000 or request a quote today.