In product development and OEM sourcing, even the smallest details can determine success. One of the most critical—and often overlooked—details is zipper terminology. Understanding the language of zippers ensures smoother communication with suppliers, fewer design errors, and stronger performance in final products. Whether you’re sourcing heavy-duty zippers for automotive seating, water-resistant tent zippers for outdoor gear, or antimicrobial zippers for healthcare soft goods, the right terminology prevents costly mistakes.

LenZip, a U.S.-owned zipper manufacturer trusted by OEMs since 1946, specializes in engineering custom zippers that meet strict requirements for automotive, tactical, outdoor, and medical applications. To help engineers, buyers, and designers, we’ve created this glossary of 10 zipper terms you should know—plus a few extras that will set you apart in technical conversations.

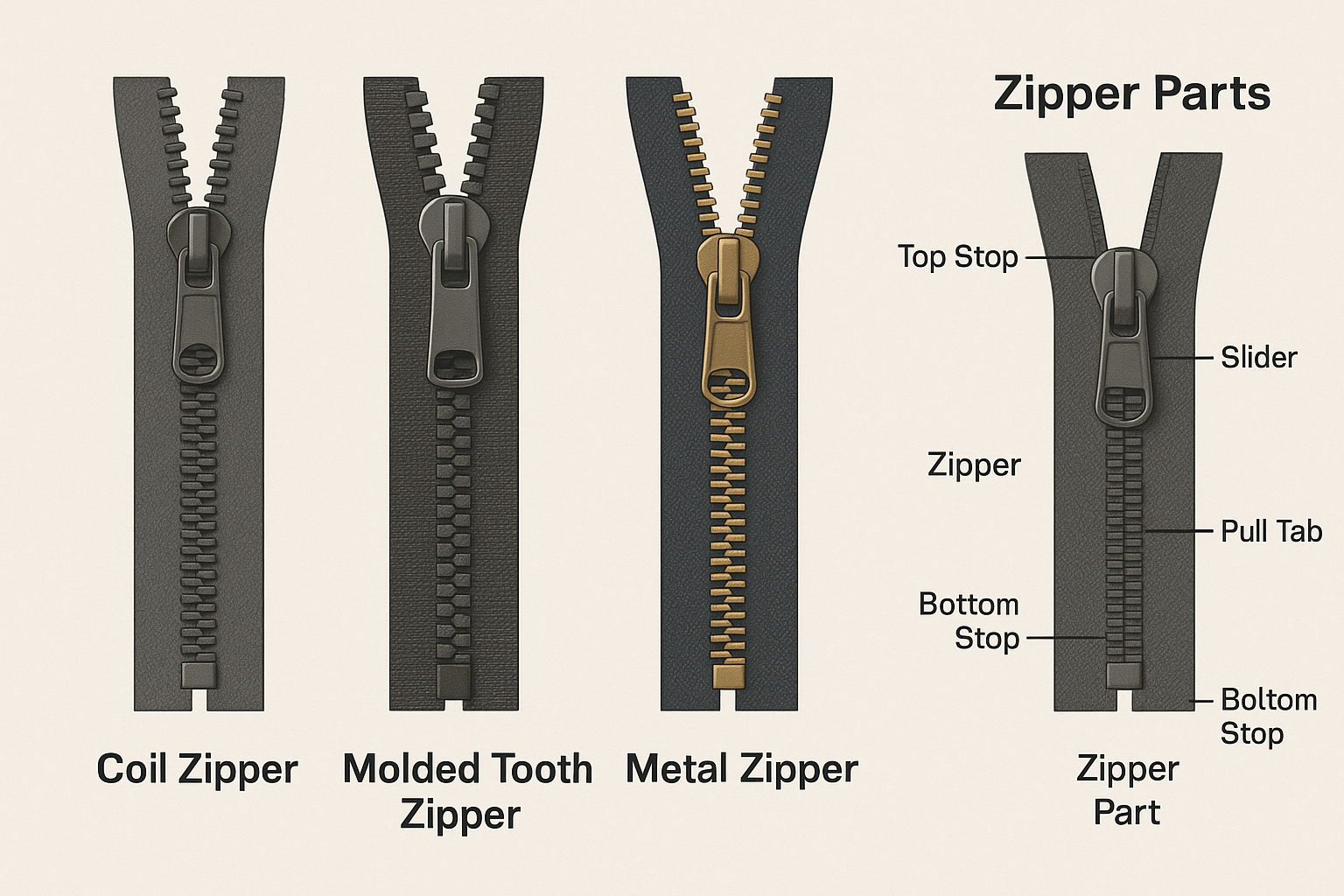

Essential Zipper Parts Explained

At the heart of every zipper are components that determine performance, reliability, and durability.

Zipper teeth (or elements) are the interlocking parts that create closure. They come in three main types: coil zippers (lightweight, flexible, ideal for seat covers and tents), molded tooth zippers (rugged, abrasion-resistant, perfect for outdoor or industrial gear), and metal zippers (durable, classic, often used in heavy-duty or luxury goods).

The zipper tape is the fabric on either side of the teeth. Typically woven from polyester or cotton, tapes may also feature UV resistance, fire ratings, or antimicrobial coatings depending on the application.

The slider is the moving piece that opens and closes the teeth. Sliders can be auto-lock for added security or non-lock for free movement, and often incorporate specialized coatings or designs for industrial use.

Attached to the slider is the pull tab (or zipper pull), which allows easy operation. In OEM contexts, long pulls, double pulls, or branded pulls are common upgrades that enhance both function and aesthetics.

Finally, stops—small metal or plastic pieces at the top and bottom—keep the slider from running off the chain. A failure here often results in premature zipper breakdown, which is why OEMs demand reinforced, heavy-duty stops for high-stress products.

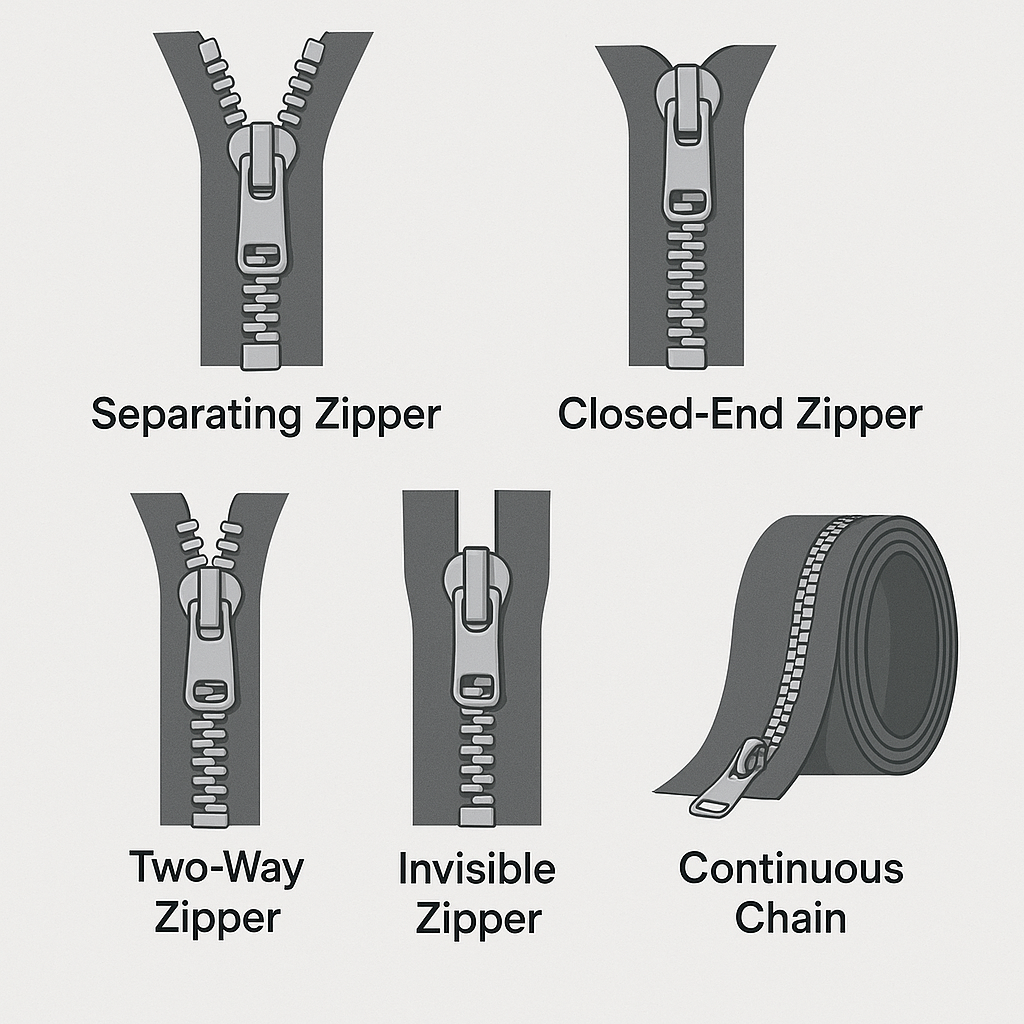

Common Zipper Types You Need to Know

Different zipper configurations serve different engineering needs.

A separating zipper (also called an open-end zipper) includes a pin and box system that lets both sides come apart completely. This type is common in jackets, convertible tops, and equipment covers that require full separation. In contrast, a closed-end zipper has a fixed bar at the base, keeping the two sides joined—ideal for cushions, trousers, and bags.

For more flexibility, a two-way zipper allows opening from both ends. This is essential in products like tactical vests, sleeping bags, or automotive seat covers, where quick access and ventilation are important.

The auto-lock slider is designed to hold the zipper in place unless the pull is actively moved. This prevents accidental opening in high-stress environments. Non-lock sliders, by contrast, glide freely, making them better suited to storage compartments and bags that require constant access.

An invisible zipper is constructed so the teeth hide beneath the tape, creating a smooth, seamless look. While not used in heavy-duty applications, they are common in fashion and specialty interiors.

Finally, continuous chain zippers are supplied on rolls so manufacturers can cut them to length, while cut-to-length zippers arrive with stops and components already in place. Both are vital for OEMs that need flexibility in production.

Additional Zipper Terminology for Professionals

Beyond the basics, there are a few zipper terms every OEM should recognize.

Gauge refers to the size of the teeth or coil, usually denoted by a number (#3, #5, #10, #20). Smaller gauges are used for lightweight apparel, while larger gauges are chosen for industrial, automotive, and military gear.

The chain describes the interlocked teeth when the zipper is closed. Components like the insertion pin and box (found on separating zippers) and specialized finishes (nickel, brass, matte, or color-matched) give engineers additional ways to specify zippers with precision.

For demanding industries, terms like fire-rated zippers, antimicrobial zippers, water-resistant zippers, and abrasion-resistant zippers are critical. These features transform a standard fastener into a mission-critical component.

Benefits of Knowing Zipper Terminology

Understanding zipper terms isn’t just about vocabulary—it’s about performance and risk management.

- Spec Accuracy: Prevents errors in sourcing, ensures the correct zipper type and gauge are used, and avoids costly redesigns.

- Supplier Communication: Creates a common language for OEMs and manufacturers, streamlining production.

- Quality Assurance: Helps engineers recognize the difference between consumer-grade zippers and custom OEM zippers designed for industrial use.

- Regulatory Compliance: Terminology around fire ratings, antimicrobial coatings, and environmental standards supports smoother certification and compliance processes.

Why Work with a U.S.-Owned Zipper Manufacturer Like LenZip

Choosing the right zipper partner is as important as knowing the terminology. LenZip stands apart as a U.S.-owned zipper manufacturer with decades of experience supplying OEMs across industries.

By sourcing domestically, OEMs gain:

- On-spec engineering that integrates seamlessly into automotive, medical, outdoor, and tactical products.

- On-time delivery with shorter lead times and less risk of overseas delays.

- Custom solutions for unique applications, from modular seating to water-resistant outdoor gear.

- Supply chain security, ensuring production remains reliable and compliant.

For over 75 years, LenZip has helped manufacturers design products that perform under pressure—because every zipper matters.

Conclusion

Zippers may seem simple, but for OEMs and engineers, they are mission-critical components. By mastering these 10 zipper terms you should know, manufacturers gain an edge in sourcing, compliance, and product reliability. From teeth, tape, and sliders to separating zippers, gauges, and continuous chains, this terminology gives professionals the clarity to specify the right closure every time.

LenZip is proud to serve as a trusted, U.S.-owned zipper partner since 1946—engineering custom OEM zippers that perform in the automotive, medical, outdoor, and tactical industries. Ready to put this knowledge into practice? Contact LenZip today for zipper solutions designed to elevate your products.

FAQ

What are the main parts of a zipper called?

The essential zipper parts are the tape, teeth, slider, pull tab, and stops. Each part affects durability and function in OEM applications.

What does zipper gauge mean?

Zipper gauge measures the size of the teeth or coil, typically listed as numbers like #3, #5, or #10. Higher numbers mean stronger, heavy-duty zippers.

What’s the difference between separating and closed-end zippers?

Separating zippers allow the two sides to fully disconnect, while closed-end zippers remain fixed at the base.

What is a continuous chain zipper?

A continuous chain zipper is supplied on a roll so OEMs can cut custom lengths and add sliders as needed, ideal for industrial and large-scale production.

Why should OEMs choose a U.S.-owned zipper manufacturer?

Working with a U.S.-owned supplier like LenZip provides reliable quality, shorter lead times, and secure domestic supply chains.