To most people, a zipper looks like a simple closure. But for OEMs, engineers, and product designers, understanding the differences between zippers is essential. The right zipper can determine whether a seat cover passes compliance, whether a tent holds up in the field, or whether a healthcare mattress meets hygiene standards.

At LenZip, a U.S.-owned zipper manufacturer since 1946, we’ve built our reputation on helping manufacturers choose the best zipper solutions for their applications. This guide explains the differences between zipper types, sizes, and designs—so you can specify closures that perform on-spec, on-time, and in every condition.

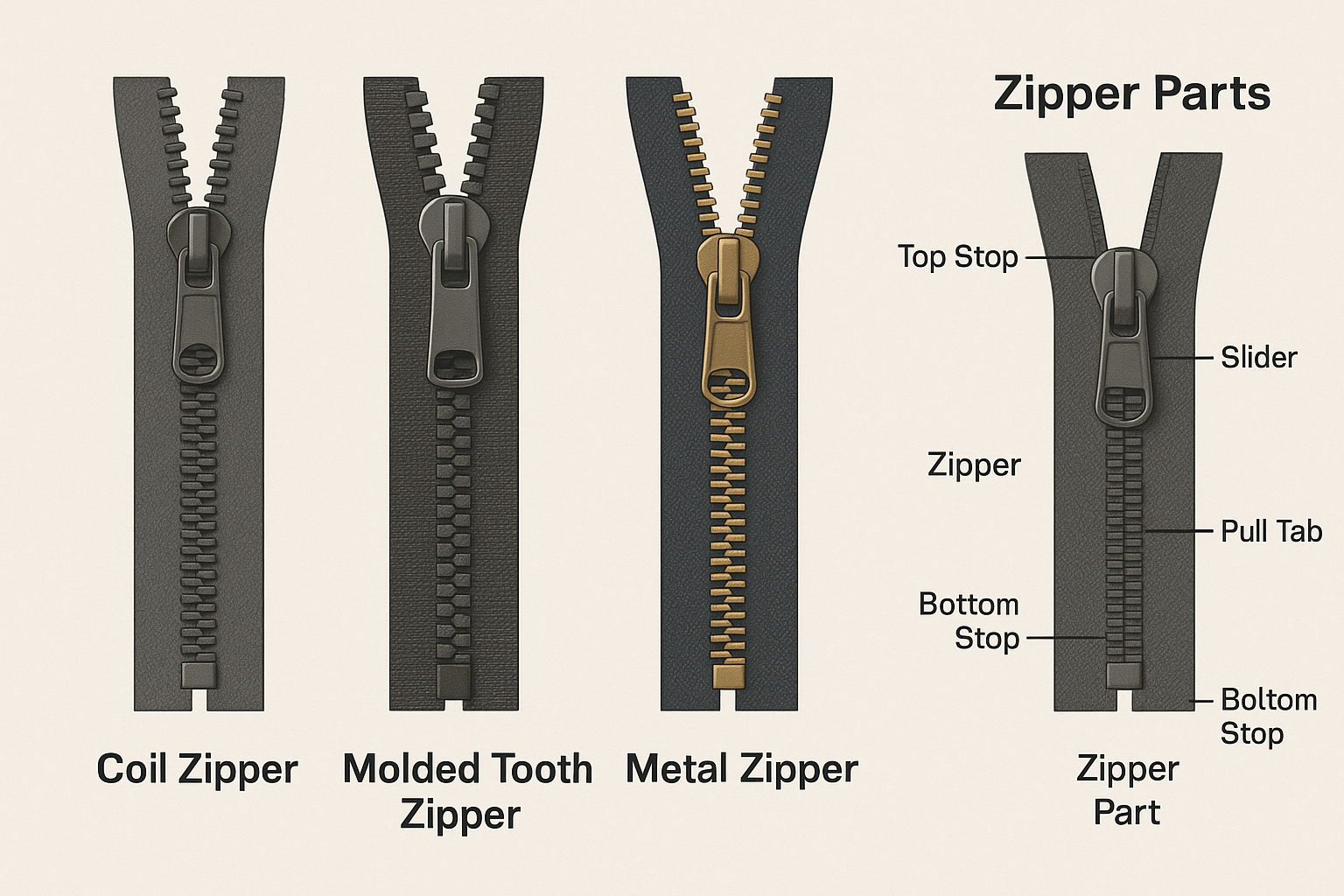

Zipper Types Explained

Zippers fall into several main categories, each with specific strengths and uses. Coil zippers are made of coiled nylon or polyester monofilament, offering flexibility, abrasion resistance, and smooth operation—perfect for curved applications like seat covers, cushions, and lightweight outdoor gear. Molded tooth zippers are created by injection-molding durable plastic teeth directly onto the tape, making them rugged, chemical-resistant, and reliable in tactical packs, industrial covers, and marine gear. Metal zippers use brass, nickel, or stainless steel teeth clamped to the tape. They provide maximum strength and a classic appearance, often used in heavy-duty luggage, leather goods, industrial enclosures, and luxury interiors.

Other specialized options include invisible zippers, where the teeth are hidden beneath the tape for a clean finish in apparel, and specialty engineered zippers, such as water-resistant, fire-rated, antimicrobial, or oversized gauges (#10–#20) for demanding OEM applications like tents, automotive seating, and hospital mattresses.

Separating vs. Closed-End Zippers

Another key distinction is whether the zipper comes apart at one end. Separating zippers, often called open-end zippers, use an insertion pin and box to allow both sides to fully separate. They are common in jackets, covers, and tents. Closed-end zippers remain fixed at the bottom thanks to a stop, making them ideal for cushions, upholstery, bags, and equipment cases. Two-way zippers add further versatility, using dual sliders that open from both ends to improve ventilation, access, or usability in gear like tactical vests and outdoor enclosures.

Zipper Sizes and Gauges

Zipper sizing, or gauge, refers to the width of the teeth when closed. Smaller gauges such as #3 and #4 are used in apparel, handbags, and cushions. Medium gauges like #5 through #7 are found in jackets, duffel bags, tents, and backpacks. Larger gauges such as #8 and #10 serve heavy-duty purposes, including industrial clothing, vehicle covers, and large canopies. Oversized zippers, often #20 or greater, are required for structural fabrics, modular shelters, and industrial enclosures where load-bearing strength is critical. Choosing the correct gauge ensures zippers withstand abrasion, weight, and repeated use without failure.

Industry Applications for OEMs

The difference between zippers is especially clear in OEM and industrial applications. In automotive interiors, hidden or fire-rated zippers are specified for seat covers, upholstery, and convertible tops, all of which must comply with FMVSS 302 flammability standards. In healthcare soft goods, antimicrobial and fluid-resistant zippers are essential for hospital mattresses, cushions, and equipment covers, where compliance with FDA and CE requirements protects both patients and staff. Outdoor gear and tents demand water-resistant, UV-resistant, and oversized zippers to withstand exposure, while tactical and military gear relies on molded tooth and abrasion-resistant zippers to meet MIL-SPEC requirements in harsh conditions. In industrial covers and enclosures, chemical-resistant and heavy-duty zippers ensure that equipment and protective barriers can perform in mining, energy, and construction environments.

Custom OEM Zippers vs. Off-the-Shelf

The biggest difference isn’t always the type of zipper, but whether it was engineered specifically for your product. Off-the-shelf zippers may be inexpensive, but they often corrode, jam, or fail compliance testing. Custom OEM zippers from LenZip, on the other hand, are designed to match exact specifications in length, gauge, tape, pull style, and coatings. They are engineered to comply with standards such as FMVSS, NFPA, OEKO-TEX, REACH, and RoHS. With options like antimicrobial coatings, waterproof tapes, or fire-resistant construction, LenZip ensures OEMs receive zipper solutions that last.

Conclusion

So, what is the difference between zippers? It comes down to construction, size, design, and engineering. For OEMs, those differences directly impact product durability, safety compliance, and customer satisfaction. Partner with LenZip, a U.S.-owned zipper manufacturer, to ensure your products close with reliability and perform under every condition. Whether you need coil zippers for seating, molded tooth zippers for tactical gear, or oversized water-resistant zippers for tents, LenZip delivers custom OEM solutions trusted by industry leaders since 1946.

FAQ

What is the difference between coil and molded zippers?

Coil zippers are lightweight, flexible, and smooth-running, ideal for upholstery and apparel. Molded tooth zippers are rugged, abrasion-resistant, and better suited for outdoor, marine, and tactical gear.

What is the difference between separating and closed-end zippers?

Separating zippers fully detach at one end, as in jackets and tents, while closed-end zippers remain joined at the bottom, used in cushions, bags, and equipment cases.

What zipper size is best for heavy-duty use?

Gauges #8–#10 are most common in industrial and outdoor gear, while #20 and larger zippers are used for large enclosures and structural fabrics.

Can zippers be water-resistant or fire-resistant?

Yes. Water-resistant zippers use coated tape or sealed designs, while fire-rated zippers meet strict safety standards like FMVSS or NFPA for compliance.

Why choose a U.S.-owned zipper manufacturer?

Working with LenZip ensures engineering expertise, faster turnaround, and secure supply chains—critical advantages for OEMs in automotive, healthcare, tactical, and industrial sectors.