When negative-pressure control or sterile barriers matter, “waterproof” isn’t enough. Airtight, RF-weldable zippers maintain seals under differential pressure, survive repeated disinfection/sterilization, and integrate cleanly into TPU/PU-coated medical fabrics—without stitch holes or adhesives. For isolation tents, portable cleanrooms, biocontainment suits, and medical device covers, the closure is a critical component of system performance—not an accessory.

Why it fits medical/biocontainment:

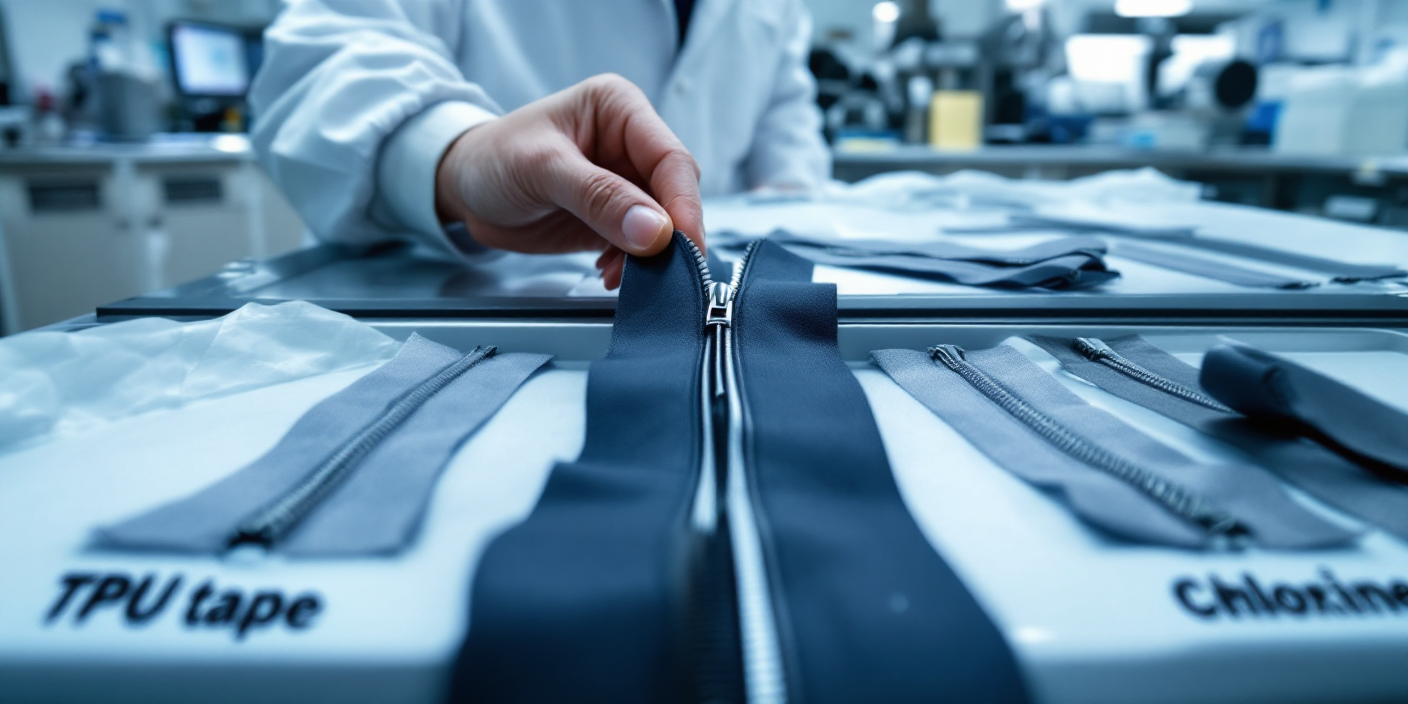

Waterproof closures can block liquid yet leak under vacuum/PSI differentials typical of isolation environments. Gas follows micro-paths at teeth interfaces and any stitch perforation. Airtight systems pair low-permeability materials with RF-welded TPU/PU tapes to form a continuous membrane and repeatable leak-down performance after cycling. See: Zipper Testing & Validation · How Zippers Are Tested

Airtight Closures for Negative-Pressure Control

The “waterproof ≠ airtight” distinction drives specification quality. In negative-pressure tents and positive-pressure clean spaces, small differentials generate continuous driving forces for gas migration. True airtight zipper constructions address this through low-permeability tapes, tight tooth geometry, and RF-welded integration that eliminates stitch-hole leak paths. Acceptance is demonstrated through pressure-decay leak testing at operational differentials and cycle/flex retention, not just short water exposure.

Related reading: Zippers & Harsh Chemical Environments

RF-Weldable Integration with Medical Fabrics

Compatible substrates: TPU-coated and PU-coated textiles; selected medical vinyls. We provide starting weld windows (power/dwell/pressure) and seam geometry guidance; you validate on your fabric stack-up.

- Lap or lap-felled seams for smooth, cleanable panels and garments

- Weld-width control and electrode alignment for dimensional consistency

- QC checkpoints: visuals + peel/shear coupons + pressure leak checks

Implementation guide: Integrating Zippers into RF-Welded or Heat-Sealed Seams · Materials: Zipper Materials & Finishes

Built to Withstand Sterilization & Disinfection

Designed for healthcare cleaning protocols and repeated cycles. We support validation to your chemistry and cycle counts:

- Alcohols (IPA 70–91%): frequent wipe-downs

- Chlorine disinfectants (hospital ranges): stabilized formulations available

- Hydrogen Peroxide Vapor (HPV/aHP): room/equipment decon workflows

- Steam sterilization (121 °C): available materials/hardware options for applications requiring limited autoclave cycles—confirm counts during qualification

Final limits depend on specific polymer, coating weight, and hardware; we supply datasheets and sample test plans to qualify on your device/shelter. See: Why Zippers Matter in Healthcare

Components for Clean, Airtight Operation

- TPU-coated polyester (low-wick) tapes reduce capillary migration

- Engineered tooth resins for low-temp flexibility & UV stability

- Low-profile sliders for tunnel seams and gloved operation

- Corrosion-safe hardware (stainless or zinc-free) for repeated cleaning/steam

Explore components: Custom Zippers · Sliders · Continuous Zippers · All Products

Validated Performance (What We Document)

We support system-level validation on your assemblies and provide documentation packages:

- Pressure-decay / leak-down at operating differentials

- Burst margins relative to spec

- Flex-under-pressure and thermal cycling retention

- Peel / shear acceptance targets for QC release

- Lot/batch traceability, REACH/RoHS declarations, and CAD/datasheets

Helpful: How to Read Zipper Spec Sheets · Zipper Load Testing Explained · Resources · Why Choose Lenzip

Typical Medical/Biocontainment Uses

- Isolation tents & portable cleanrooms: airtight entry panels that survive frequent cycles and sterilant exposure

- Biocontainment suits/PPE: rear-entry closures, pass-throughs; smooth, cleanable exterior geometry

- Medical device/enclosure covers: sterile-field access with repeatable pressure-rated closures

See also: Healthcare Industry · Fabric Structures · Tents & Shelters

Seal Your Medical/Biocontainment Spec with Lenzip

Send your fabric, disinfectant/sterilant list, and target differential pressure/temperature. We’ll return a spec-matched zipper construction (gauge, TPU/PU tape, slider/hardware), a starting RF weld window (power/dwell/pressure), and a QC checklist (peel/shear + leak/decay) you can hand to production. U.S.-owned • Engineering support • Minimums as low as 25 units.

- Request a Sterilization & PSI Spec Match → https://lenzip.com/request-a-quote/

- Quick help: Customer Support → https://lenzip.com/customer-support/

- Explore components: Custom Zippers · Sliders · Continuous Zippers · All Products

FAQs

Can we RF-weld to our medical fabric?

Yes—TPU/PU-coated fabrics and selected vinyls. We’ll provide a starting weld window; you validate on your stack-up.

Guide: RF-Weld Integration

What peel/shear should we target?

We share acceptance targets and coupon test plans; final thresholds align to your loads and risk profile.

More: Zipper Testing & Validation

Do sterilants/autoclave cycles affect seals?

Chemistries and cycle counts vary—select stabilized TPU with stainless hardware where needed and validate cycles on your device/shelter.