When an equipment cover splits at the seam during a routine inspection, when an industrial curtain jams halfway through a shift change, or when an HVAC access panel corrodes after a single coastal winter, the problem is rarely the fabric. It’s the zipper. For engineers specifying protective covers, curtains, and enclosures, the zipper is the mechanical weak point that determines whether a product delivers years of reliable field service or becomes a warranty headache.

At Lenzip, we engineer zippers purpose-built for the industrial environment: dusty generator enclosures, UV-blasted equipment covers, salt-laden coastal sites, and temperature extremes near HVAC units and engines. Our closures combine UV-stable tape construction, corrosion-safe hardware, and integration methods tailored to canvas, vinyl, and coated technical fabrics. Whether you’re designing a generator cover for a remote telecom site or an industrial partition for a manufacturing floor, the zipper needs to operate smoothly on day one and day 1,000—even when fouled with dust or exposed to the elements.

Built for Outdoor & Industrial Exposure

Industrial covers and enclosures live hard lives. A compressor cover on an oil rig sees salt spray and temperature swings. A canvas generator cover in Arizona endures 12 hours of summer UV daily. An HVAC access panel on a rooftop cycles between scorching metal surfaces and nighttime cold. For zippers in these applications, environmental durability isn’t optional—it’s the baseline requirement that separates a functional closure from a field failure.

UV, Dust, Moisture, and Vibration—Designing for Long Service Life

Ultraviolet radiation breaks down polymer chains in zipper tapes and elements, leading to embrittlement and reduced tensile strength. We address this through UV-stable TPU and polyurethane-coated tapes on low-wick polyester cores. Testing to ASTM G154 using UVA-340 lamps—which replicate the damaging 295–365 nm spectrum of natural sunlight—our zipper tapes retain ≥70% of original tensile strength after 2,000 hours of accelerated exposure. See our reference notes in zipper testing standards and how zippers are tested.

Dust and particulate ingress represent another persistent challenge. Equipment covers near crushing operations, cement plants, or desert installations encounter fines that infiltrate zipper chains and bind sliders. Our anti-jam tooth geometry features wider spacing at engagement points and radiused surfaces that deflect debris rather than trap it. Even when a zipper accumulates dust, glide force remains within operational limits—details in the section below and our zipper load testing explained article.

Moisture presents a dual threat: liquid water that can wick along seams and humidity that accelerates corrosion. Low-wick polyester tape construction limits capillary action along the seam (see zipper materials & finishes), and coated tapes with heat-sealable films add another barrier for splash-prone installs. Vibration from running equipment can cause slider creep—so our sliders and stops are verified under cyclic loading, with top stop holding strength >90 N on standard #5 and bottom stop retention >80 N.

Corrosion-Safe Hardware and Low-Wick Tapes

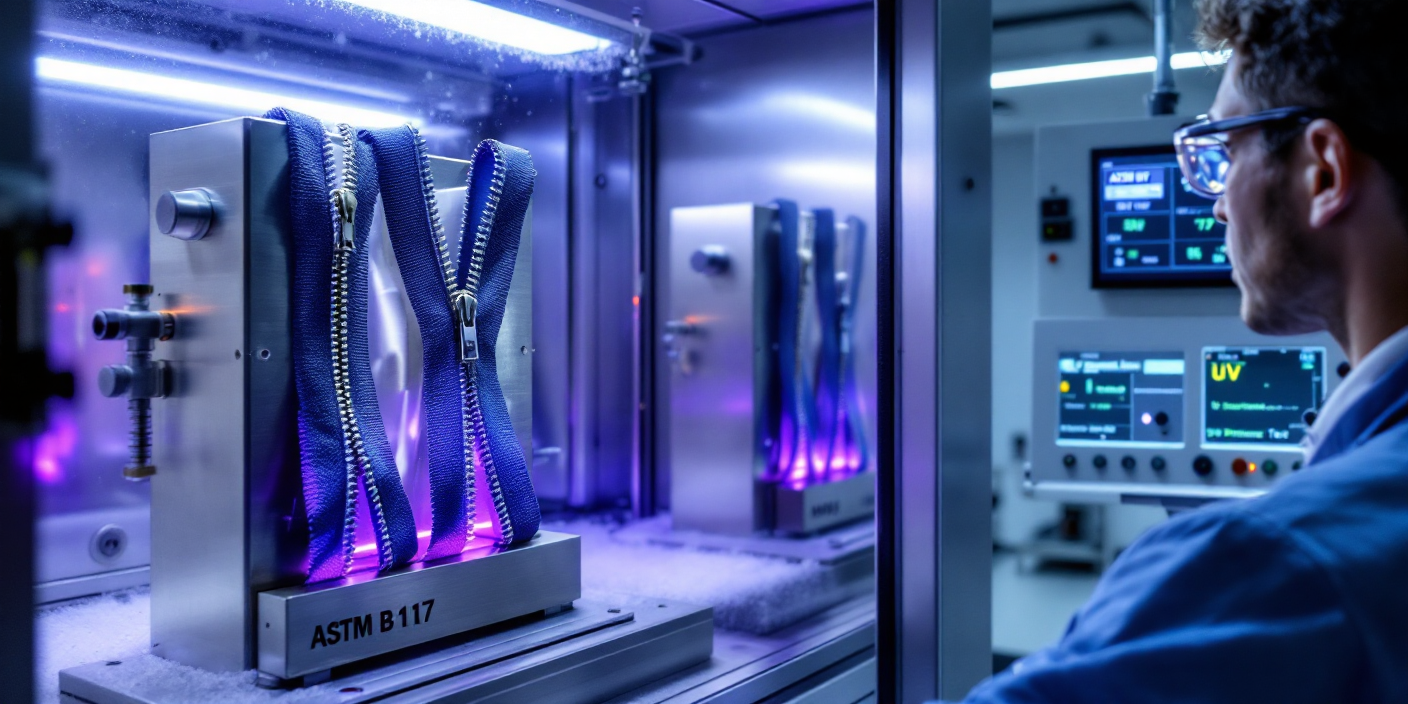

Hardware corrosion is the silent killer of industrial zippers. We specify 300-series stainless or zinc-free alloy hardware with passivation treatments that extend corrosion onset. In accelerated salt fog testing per ASTM B117, our hardware options show no visible corrosion for 500+ hours at 35 °C. For glare-sensitive sites, matte/low-glare slider finishes maintain corrosion resistance while reducing reflection—useful on rooftops and yards.

Low-wick tape construction deserves emphasis. Traditional cotton or untreated polyester tapes can act as wicks, drawing moisture into the cover through capillary action. Our polyester tapes are engineered with tighter weaves and lower surface energy to resist wicking. Combined with edge sealing or binding during installation (below), this minimizes a primary moisture path. If you’re weighing trade-offs, start with choosing the right zipper.

Smooth, Reliable Operation in Real Conditions

A zipper that’s difficult to operate becomes a zipper that gets forced, jammed, or bypassed. For field technicians and warehouse teams, closures must open and close smoothly even under less-than-ideal conditions.

Glide force targets (clean vs dusty)

- Clean: 3–6 N for #5 gauge—one-handed operation, strong engagement.

- Dust exposure (fine particulate, 500 cycles): typically ≤12 N—still operable with gloves.

This controlled behavior stems from tooth/slider design: anti-jam geometry, forgiving entry angles, and chamfered throats that guide misaligned teeth back into engagement. For heavy dust (mining/aggregate/ag), tolerance to contamination preserves usability between maintenance cycles. When sizing, refer to the zipper gauge chart.

Chain crosswise tensile strength

- #5: >600 N per 2.5 cm

- #7: >650 N

These exceed typical wind and fabric-tension loads for covers/partitions (see zipper load testing explained).

Abrasion Resistance Where Covers Flex at Edges

Corners and wrap points are the wear zones. Using Taber H-18 at defined loads, our coated tapes withstand 2,000+ cycles to appearance threshold; Martindale tests at typical bend radii confirm functional strength well beyond 10,000 rubs. The polyester core provides dimensional stability; TPU/PU coatings add a sacrificial layer that absorbs edge rub so fibers don’t.

Choose the Right Seal Level & Gauge

Not all covers need the same sealing or strength. Matching seal level and gauge prevents both under- and over-specification.

Weather-resistant vs airtight use cases

- Weather-resistant: resists rain/splash and dust; not hermetic. Pair coated tapes with stainless/passivated hardware and sealed edges.

- Airtight/pressure-rated: specialized closures with sealing elements for differential pressure or contamination control; validate per your spec (see testing standards).

Gauge/chain selection for curtains, panels, and large covers

- Small access doors/light curtains: #3–#5 for flexibility.

- Large covers/heavy vinyl enclosures: #5–#7 for strength vs weight.

- Extreme duty/oversized panels: #10 for maximum robustness.

If you’re choosing between continuous supply and finished assemblies, compare continuous vs finished zippers.

Integration with Canvas, Vinyl & Coated Fabrics

A zipper is only as reliable as its integration method. Material dictates attachment.

Stitching best practices + edge sealing/binding

Use heavy-duty lockstitch or double-needle with UV-resistant polyester or PTFE thread (6–8 SPI). Position seams to keep tape flat, reduce stress, and seal the stitch line (binding or seam sealant) to block capillary wicking. Guidance in integrating zippers into RF-welded or heat-sealed seams also notes stitch-vs-weld decision points.

Heat-seal/RF-weld options for coated fabrics

For PVC/TPU and similar substrates, RF or heat sealing eliminates needle holes and delivers higher peel strength (often >15 N/25 mm) and smooth, flush seams—ideal for splash-resistant or washdown environments. See process windows and compatibility in integrating zippers into RF-welded or heat-sealed seams and validate materials against zipper materials & finishes.

Maintenance & Field Service

Zippers in industrial duty are maintenance items. A light, regular protocol preserves glide and extends service life.

Cleaning & lubrication cadence

Dry-brush loose particulate; wash with mild detergent if oily/sticky contamination is present. After drying, apply silicone or PTFE-based dry lube (avoid petroleum oils on TPU/PU). For frequency, follow zipper maintenance & care—typically every 3–6 months outdoors; more often for high-cycle curtains.

Slider replacement

Worn sliders show rising glide force or inconsistent engagement. Replace in the field with matched parts; a $2 slider swap can prevent a $50 zipper replacement. For long runs and heavy cycles, consider heavy-duty zippers and keep spare sliders on hand.

Storage Temperature/Humidity Notes to Prevent Embrittlement

Store covers cool, dry, and out of UV. Avoid sustained >50 °C; prevent very low RH (<20%) that can dry lubricants and embrittle plastics. After storage, inspect for cracking/corrosion and refresh lube before redeploying.

Applications We Support

- Generator/engine and compressor covers (UV, vibration, weather load)

- HVAC access panels and utility enclosures (corrosion, thermal cycling)

- Industrial curtains/partitions and weather panels (high cycle, dust)

Engineering Support & Compliance

We ship with the documentation your QA and procurement teams need.

- Datasheets and CAD: gauge, dimensions, mechanicals, tape/coating options—see how to read zipper spec sheets.

- Environmental matrix: UV (G154), salt fog (B117), cold-flex, abrasion, glide-force curves—see zipper testing standards and how zippers are tested.

- Compliance & traceability: REACH/RoHS compliance, batch/lot tracking, CoCs per shipment.

Seal Your Cover/Enclosure Spec with Lenzip

Share your application requirements, fabric type, and environmental conditions. We’ll return a spec-matched construction (tape/coating, chain size, slider/hardware), integration guidance (sewn or RF/heat-sealed), and QC targets your team can hand to production. U.S.-owned • Engineering support • Minimums as low as 25 units.