When sourcing fasteners for plate carriers, assault packs, or field uniforms, the zipper isn’t an afterthought—it’s mission-critical hardware. A jammed slider during rapid egress, a reflective pull compromising concealment, or a zipper that clogs with sand after the first patrol can cascade into operational failure or worse. Military and tactical applications demand fasteners engineered for environments where extreme temperature swings, abrasive particulate, saltwater exposure, and thousands of open-close cycles under load are standard operating conditions—not edge cases.

If you build tactical soft goods, start with field-tested specs and suppliers who can document performance. Lenzip’s application pages for Tactical Gear, adjacent Outdoor Gear, Safety, Fire/FR, Marine Fabricators, and Tents are good reference points when you’re aligning chain, sliders, and tape to mission environments.

What Makes a Zipper “Military-Grade”?

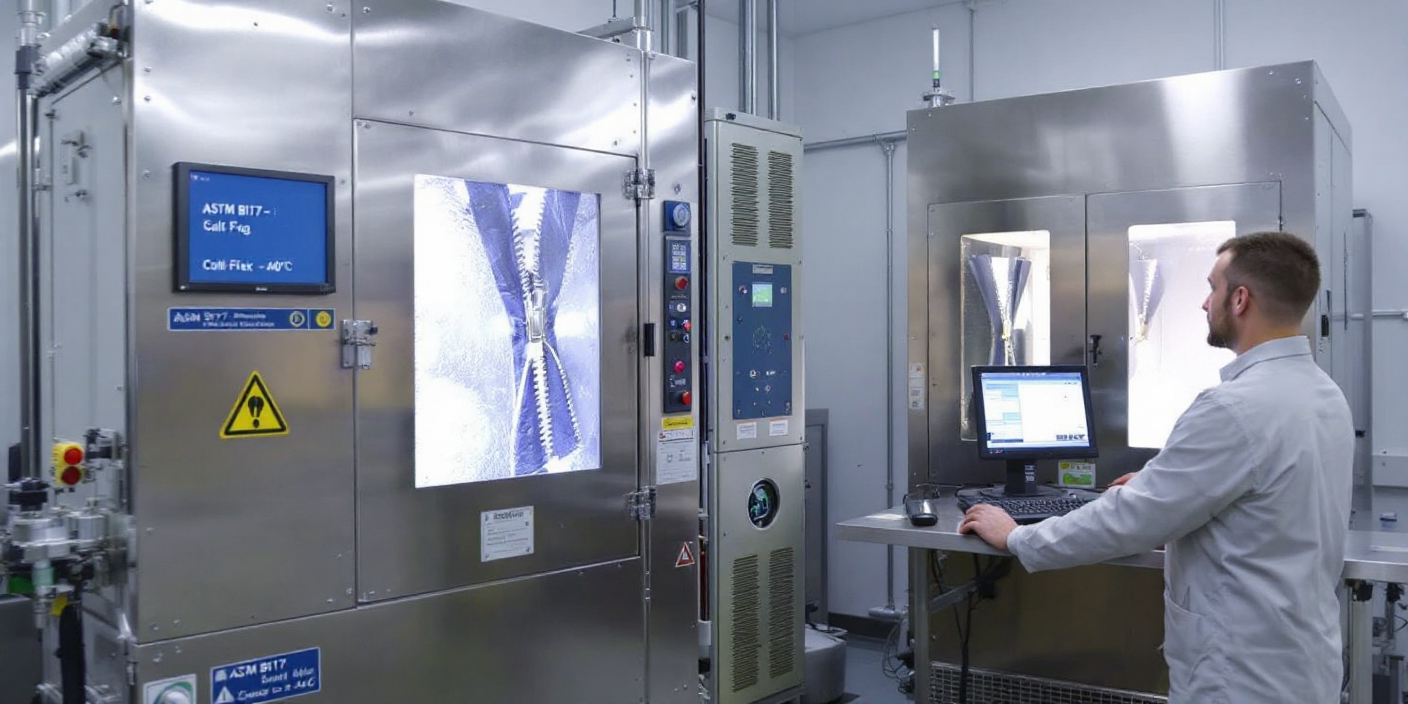

Military-grade here means documented performance under conditions that destroy consumer fasteners. Think dust/sand intrusion, mud immersion, salt-fog corrosion, perspiration, freeze–thaw cycling, UV, long service life, and industrial laundering. (See Zipper Testing Standards and How Zippers Are Tested for Strength, Corrosion, and Fatigue.)

Chain type: choose the dominant failure mode

- Molded tooth (acetal): excels in grit; wider spacing lets particles pass, making it a default for main pack openings and rucks.

- Metal: top heat tolerance for hot-surface contact/industrial laundry; manage weight and low-gloss finishes to avoid reflectivity.

- Reversed coil: smooth, low-snag exterior that pairs well with storm flaps/garages on outerwear and shelters; spec heavier gauges + quality autolock sliders for lateral strength.

Gauge mapping

Use the Zipper Gauge / Chain Size Chart.

- #10: primary closures on large packs/shelters where lateral strength + high cycles are expected.

- #8: plate carriers, pouches, secondary compartments (balanced strength vs bulk).

- #5: admin pockets/internal org where low profile matters.

Tape, coatings & signature management

High-tenacity polyester for baseline durability; aramid-blend options for FR requirements (see Fire).

Low-gloss/IRR colorways (Coyote, Ranger, Black, Wolf Grey) to match NIR signature—get spectro documentation, not just visual matches. (See Zipper Materials & Finishes and Zipper Coatings & Finishes.)

Sliders & pulls (noise, grip, retention)

Autolock to prevent creep under vibration.

Reverse bail / glove-friendly forms; paracord or rubberized pulls to eliminate metallic jingle.

Double pulls on long runs for venting/partial access. (Browse Sliders for Zippers.)

Water resistance ≠ waterproof

Use a system: coated/laminated tapes + reversed coil + garages. For sustained immersion/pressure, you need seam welding/gaskets—don’t over-promise. (See Integrating Zippers into RF-Welded or Heat-Sealed Seams.)

Verification & compliance

Ask for test reports: sand/dust, salt spray, temp cycle, pull-force after contamination. If contracts require Berry, TAA, MIL-DTL, or IRR/NIR docs, obtain written supplier certification per lot. Don’t assume—verify and retain. (Helpful primer: Choosing the Right Zipper for Your Application.)

Quick Spec Matrix by Use Case (cheat sheet)

- Plate carriers/pouches: #8 reversed coil or molded; matte IRR colors; silent pulls.

- Assault packs/rucks: #10 molded for mains; double pulls; garages for grit.

- Uniforms/outerwear: reversed coil; FR/heat-resistant tapes as required (see Safety & Fire).

- Shelters/covers: long runs in #10 coil or molded; water-resistant tapes; cold-crack validated (see Tents).

- Maritime/coastal: corrosion-managed hardware + rinsing guidance (see Marine Fabricators and Preventing Corrosion for Marine Zipper Care).

Top 10 Zipper Manufacturers for Military & Tactical (Ranked by Buyer Criteria)

Criteria: #8/#10 availability; molded/metal/coil breadth; IRR/low-gloss options; FR/heat-resistant tape alternatives; water-resistant tape; matched slider ecosystems (autolock/reverse bail/double pull); continuous chain; realistic MOQs; transparent lead times; test documentation. (Compliance like Berry/TAA must be explicitly verified.)

1) Lenzip (U.S.-owned)

Lenzip ranks first for tactical sourcing thanks to breadth + support. Coil, molded, and metal chains; minimums as low as 25 units for prototyping and low-rate runs; continuous chain by the yard cut to spec; matched autolock, reverse bail, and double-pull sliders.

Engineering support helps lock specs, approve samples, and maintain color control (including low-gloss tactical palettes). Stocking/blanket programs, multi-site shipping, and custom pack/label reduce ops overhead for distributed sew lines.

Guardrails: U.S.-owned does not mean Berry by default—request documentation if required. Lenzip does not make invisible zippers; right/left orientation applies only to open-end types.

Request a Quote | (847) 368-9000 | Explore Tactical Gear and Custom Zippers

2) YKK (Japan/USA)

Large global footprint and process control. VISLON® molded (#5–#10), metal with aramid/FR tape options, and coil in tactical colorways; water-repellent lines (e.g., film-backed) for outerwear/shelters. Good slider ecosystem breadth.

Best for: programs needing global availability and consistent lot-to-lot.

Guardrails: Berry/TAA availability varies by line/plant—get written confirmation per SKU/lot.

3) Ideal Fastener (USA)

Long U.S. manufacturing history with mil-spec experience. Brass/Delrin across #4.5–#10; aramid tapes for FR garments; offers breakaway/quick-release variants for egress.

Best for: domestic builds prioritizing metal/molded with FR tape choices.

Guardrails: Verify Berry/mil-spec conformance by exact part number and lot.

4) Opti by Coats (EU)

Opti P-series molded (incl. total-plastic corrosion-resistant variants); Hydro-style water-repellent treatments; quick-release options for uniforms. Strong European compliance support.

Best for: EU-based tenders and apparel programs needing WR + uniform features.

Guardrails: Check U.S. contract compliance (Berry/TAA) per product.

5) Riri Group (Switzerland/Italy)

Premium engineering/finishes; STORM/PU-integrated constructions; Meras coil for low-profile applications; excellent slider/puller design quality.

Best for: flagship kits where finish, feel, and smooth operation matter.

Guardrails: Higher MOQs/price; compliance is program-specific—confirm before spec.

6) SBS (China)

High capacity, broad catalog (molded/metal/coil), WR treatments, custom colors, fast sampling.

Best for: commercial tactical/international lines with tight cost targets.

Guardrails: Not Berry; require third-party testing and clear QC gates.

7) Talon International (USA presence)

Legacy brand with modern workwear/tactical-friendly options (curved zips, reinforced builds). U.S. account support; decent lead-time agility on common gauges.

Best for: quick-turn commercial programs and brand-driven trims.

Guardrails: Verify any compliance (Berry/TAA) per product family.

8) KCC (Taiwan/Vietnam)

Customization-forward: NIR/IRR treatments, specialized sliders/pullers, FR/WR variants.

Best for: differentiation (signature pulls/ergonomics) without boutique pricing.

Guardrails: Mid-range MOQs; confirm compliance scope and lab reports.

9) Kroko (Belgium)

Military/police focus; IRR treatments; in-house lab for test/cert packages; strong EU tender alignment.

Best for: NATO/EU government programs needing documentation depth.

Guardrails: Not Berry; plan for EU-centric lead times/logistics.

10) RHF (China)

Wide range across nylon/resin/metal + “waterproof” constructions; flexible MOQs; aggressive sampling.

Best for: value-engineered commercial tactical SKUs at volume.

Guardrails: Validate performance with independent tests; set incoming QC and PPAP-style checks.

Chain Type Deep-Dive (Molded vs Metal vs Reversed Coil)

Molded tooth: best for sand/impact; tooth spacing sheds grit; bulkier/heavier.

Metal: highest heat tolerance + perceived ruggedness; manage matte finishes and corrosion; watch weight.

Reversed coil: low-snag, smooth glide; great under flaps/garages; spec heavier gauges + quality sliders for strength parity.

Pick based on dominant failure mode: grit → molded; heat/industrial wash → metal; snag/low profile → reversed coil. (Also see Why Zipper Reliability Matters in Military & Tactical Uniforms and Load-Bearing Zippers.)

Finishes, IR/NIR & Visual Discipline

- Require low-gloss finishes on teeth + sliders to kill glint.

- Specify IRR colorways and request NIR reflectance curves (700–1100 nm) to match surrounding textiles.

- Use textured/rubberized or paracord pulls for noise + shine control.

- Lock Delta-E tolerances and lot-match to avoid in-kit color patchwork.

- See Tactical Gear for program-level considerations.

FR/Heat & Chemical Considerations

For FR: aramid-blend tapes (Nomex/Conex/Lenzing FR); plastic components must pass vertical flame/heat exposure criteria; metal + aramid offers max heat tolerance (weight tradeoff).

For chemicals (fuels/solvents/cleaners): run compatibility tests—measure dimensional change/strength retention/slider function post-exposure.

Define temperature + dwell time (instant contact vs sustained), especially for industrial laundry.

Align spec choices with Safety and Fire/FR requirements. (For deeper reading: Zippers in Harsh Chemical Environments.)

Weatherization & Cold

Coated/laminated tapes + reversed coil + garages = practical rain resistance; not immersion-proof.

Cold-crack performance to program minimums via chamber cycling; UV stability via inhibitors + accelerated aging for desert/maritime deployments.

For shelters/covers, cross-check Tents and Marine Fabricators.

From Sample to Qualification

-Sample combos in #8/#10 with intended fabrics (Cordura, laminates, webbing).

-Contamination cycles: dust/sand + 500 pulls; wet-dry; freeze–thaw.

-Quantify pull/glide forces with a gauge (fresh vs post-cycles).

-Scale: ensure continuous chain supply, matched components at volume, QC for alignment/pitch/slider torque/color.

-Docs upfront: materials, tests, compliance, lot traceability.

-Need help locking specs, samples, and matched chain/slider ecosystems?

Custom Zippers | Request a Quote

Common Failure Points & Field Fixes

- Slider spread/skip: undersized/soft slider or lateral force → upgrade to reinforced autolock matched to chain gauge; ensure chain/slider standards match.

- Grit jams: wrong chain type or no garages → use molded for mains; reversed coil + garages for garments; include rinse/maintenance guidance for beach/desert ops.

- Corrosion: metal in salt/humidity → matte/anodized/electroless finishes or all-plastic; document rinse/dry SOPs (see Marine Zipper Care).

- Noise/shine: metal jingles and glint → paracord/silicone pulls; low-gloss sliders; conceal under flaps/webbing.

- Field repair: carry spare sliders + tools if you spec repairable configs; catastrophic tape/tooth damage needs replacement. (Reference Zipper Engineering 101 and How to Read Zipper Spec Sheets.)

FAQs

Which gauge for tactical packs?

#10 for main compartments; #8 for secondaries; #5 for admin/internal. Undersizing mains invites early failure. (Check the Gauge/Chain Chart.)

Molded vs metal in sand?

Molded sheds grit better; metal for heat/industrial wash—finish for low gloss, manage weight, verify corrosion protection. (See Zippers & Extreme Environments.)

Are water-resistant zippers waterproof?

No. They resist rain/splash with coated tapes + reversed coil + garages. Immersion/pressure needs sealed systems. (Integration notes: RF/Heat-Seal Seams.)

Can I get IRR/low-gloss?

Yes—require spectrophotometry in the NIR band and batch documentation. Don’t rely on visual matching. (See Tactical Gear.)

Berry/TAA compliant?

Never assume. Request written certifications per part number and lot; retain docs for inspection.