Slider Secrets:

All About Your Zipper's Moving Pieces

Unlock zipper mystery! Learn to identify, understand, and replace zipper slider parts for DIY repair success. Get your zipper working again!

When a zipper fails — a jacket that won’t close, a tent flap that splits, or a boat cover that won’t seal — it’s easy to think the entire zipper is ruined. But in most cases, the issue isn’t the whole zipper at all. It’s one small but mighty component: the slider.

Understanding zipper slider parts can save you time, money, and frustration — and, in many cases, prevent a complete replacement. In this comprehensive guide from LenZip, a U.S.-owned zipper manufacturer with nearly 80 years of engineering expertise, you’ll learn to identify slider components, determine zipper type and gauge, and perform simple repairs that extend the life of your products.

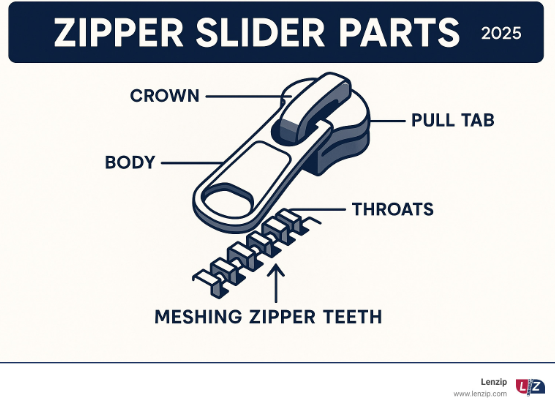

Anatomy of a Zipper Slider: The Core Components

A zipper slider is the control center of the entire zipper system. As it moves up and down, it aligns each set of teeth with precise tension and timing. The result: a seamless zip every time. But when even one part wears down or distorts, the system fails.

The main components of a zipper slider include:

Crown – The top guide that ensures the zipper tape feeds correctly into the body.

Body – The main housing that holds the internal mechanism and applies the necessary pressure.

Pull Tab – The external handle that lets you move the slider smoothly up or down.

Throats – Internal channels that mesh the zipper teeth together in perfect alignment.

When you understand how each piece contributes to the zipper’s performance, you can diagnose most zipper issues quickly.

As one repair expert explained, “We repair about 200 zippers a year on jackets, tents, sleeping bags, pants, motorcycle gear — even Jeep soft top covers and camper trailers. In most cases, it’s just the slider that fails.”

That’s good news. Because replacing a slider is usually easier, faster, and far more affordable than replacing an entire zipper assembly.

LenZip engineers each slider using precision-molded alloys and high-strength polymers designed to withstand thousands of open-and-close cycles under stress.

What Each Slider Part Does

Each part of the slider plays a specific role in zipper function.

The crown gently directs the zipper tape into position. Without it, the tape would enter at the wrong angle, leading to misalignment and stress on the chain.

The body serves as the backbone of the slider. This housing provides the structural strength required to press and interlock the teeth accurately. LenZip’s electroplated zinc-alloy and acetal resin housings ensure smooth, consistent performance, even under heavy loads.

The pull tab transfers your movement to the internal mechanism. Different tab shapes and lengths provide better ergonomics for gloves, outdoor use, or decorative finishes.

Finally, the throats are the most critical component. These interior channels apply the pressure that closes or opens the zipper teeth. If they wear or stretch — even slightly — the zipper separates or jams.

Every component must work in harmony. A single worn throat or bent pull can disable an otherwise perfect zipper.

Identifying Your Zipper Type: The First Step to a Perfect Match

Not all zippers are the same — and neither are their sliders. Using the wrong slider on a zipper is like forcing the wrong key into a lock.

Before ordering replacements or attempting a repair, identify your zipper’s type, material, and gauge.

LenZip recommends starting by examining the teeth: their shape, material, and structure will tell you everything you need to know.

Determining Zipper Type and Material

Here’s how to tell which zipper you have and what type of slider it needs:

Nylon Coil Zippers

Their teeth resemble a continuous spiral coil — flexible, quiet, and ideal for backpacks, jackets, and curved seams. Their sliders are engineered with curved throats to mesh coil teeth perfectly.

Molded Plastic Zippers

Built from acetal resin, these feature individual teeth molded directly onto the tape. They’re durable and corrosion-resistant, ideal for marine and outdoor products. Their sliders have wider throats to accommodate each molded tooth.

Metal Zippers

Made from brass, aluminum, or nickel, metal zippers provide high tensile strength and a timeless look. Common on denim, leather goods, and industrial covers, they require precision sliders designed to handle heavy bite force.

| Attribute | Metal Zippers | Plastic Zippers (Nylon Coil & Molded) |

|---|---|---|

| Durability | Strong, classic, repairable | Resistant to corrosion and UV degradation |

| Environment | Best for dry or low-corrosion conditions | Ideal for marine and outdoor exposure |

| Flexibility | Rigid, best for straight seams | Flexible for curves and dynamic seams |

| Weight | Heavier | Lightweight |

| Maintenance | May oxidize in humidity | Minimal upkeep, easy to clean |

Learn how materials affect zipper performance in Unraveling the Differences: Nylon and Polyester Explained.

How to Find the Correct Zipper Gauge (Size)

Gauge is the numerical size of your zipper, representing the closed teeth’s width in millimeters. For instance, 5mm equals a #5 zipper.

Many sliders have numbers or codes stamped on the back (such as “5C” for a #5 coil zipper). While this is helpful, always confirm by measuring — markings vary between manufacturers.

Using a ruler or digital caliper, measure the closed teeth width. Compare it to LenZip’s Zipper Gauge Chart to find your exact match.

If your zipper won’t close, measure one tooth, double it, and round down. Typical gauges are #3, #4.5, #5, #7, #8, and #10. Accuracy matters: even half a millimeter off can prevent smooth engagement.

Once you know the gauge, match it to your zipper’s type (metal, molded, or coil). This ensures perfect fit and function.

A Deep Dive into Zipper Slider Parts and Types

Sliders vary depending on function and environment. At LenZip, we’ve perfected every type — from compact auto-lock sliders to heavy-duty corrosion-resistant versions for industrial and marine use.

Auto-Lock Sliders feature a spring-loaded pin that locks when not pulled, ideal for jackets, upholstery, and outdoor covers.

Non-Lock Sliders move freely — perfect for luggage and tents requiring fast operation.

Flatlock Sliders combine sleek design and locking precision for apparel and activewear.

Double-Pull Sliders allow access from both sides, used in tents, sleeping bags, or reversible jackets.

All-Plastic Sliders contain no metal, ensuring zero corrosion in marine or chemical settings.

Each design meets ASTM D2061 and MIL-SPEC testing requirements for tensile and fatigue performance. Learn more at How Zippers Are Tested.

The Value Proposition of an American Zipper Manufacturer

Working with a U.S.-based zipper manufacturer like LenZip means gaining a partner dedicated to precision, speed, and accountability.

Our team manufactures zippers entirely in the U.S., providing superior quality control, faster delivery, and complete material traceability. That level of oversight ensures each component — from the crown to the pull tab — meets strict ASTM standards before shipping.

American production also offers customization flexibility. We engineer heat-resistant, flame-retardant, and water-resistant zipper assemblies for industries where reliability can’t be compromised.

Generational craftsmanship also sets LenZip apart. Many team members have been with us for over a decade, passing down specialized knowledge that shapes every zipper we produce.

Key Industries and Applications

Zippers play a critical role across industries — especially where performance failure isn’t an option.

Military & Tactical Gear

These zippers face extreme conditions. Berry Amendment compliance ensures LenZip’s U.S.-made zippers meet defense standards for tensile strength, flame resistance, and corrosion protection.

Outdoor & Marine Equipment

Marine-grade zippers endure saltwater, UV rays, and temperature swings. LenZip’s marine zippers combine water-resistant tapes, molded teeth, and corrosion-proof sliders that thrive in harsh climates.

High-End Apparel & Accessories

Luxury garments demand smooth, silent operation. Each zipper contributes to the tactile quality customers expect. LenZip’s Zipper Materials & Finishes program offers electroplated finishes and custom colors to complement premium fashion pieces.

Industrial & Safety Equipment

Fire-retardant zippers protect workers in high-heat environments. LenZip’s testing standards ensure performance under mechanical and thermal stress.

Medical & Cleanroom Devices

Precision-made zippers support sterilizable and hygienic products used in healthcare and lab environments.

These industries rely on domestic engineering for compliance, reliability, and product longevity.

Understanding Specialty Zipper Slider Parts

Certain zipper designs demand unique slider mechanics that enhance function and appearance.

Reverse Bale Sliders pair with reverse coil zippers, creating a smooth outer surface that hides teeth. Popular in outdoor gear and marine applications, these sliders provide a polished, water-resistant seal.

Double-Pull Sliders feature tabs on both sides, allowing dual access for tents or reversible apparel.

All-Plastic Sliders remove metal entirely, making them ideal for marine and chemical environments. They resist rust, corrosion, and even pass metal detectors undetected — perfect for travel and security applications.

Each of these specialty designs is custom-tested by LenZip to ensure seamless engagement and long-term endurance.

A Guide to Zipper Pull Tab Styles

The pull tab may seem minor, but it’s the part you touch most. Its shape, size, and design directly affect user comfort and style.

Standard Pulls work for everyday items, offering simplicity and balance.

Extended Pulls help when gloves or thick fabrics make small tabs hard to grip.

Wire Pulls provide lightweight durability for technical gear and backpacks.

Decorative Pulls add design flair to handbags or outerwear.

Reversible Pulls swing both ways, ideal for reversible garments or sleeping bags.

Each tab is designed for both form and function — and LenZip can customize pull shapes, finishes, and materials for OEM applications.

Step-by-Step Zipper Slider Replacement

Replacing a worn slider is simple and requires only basic tools.

Step 1: Remove the Old Zipper Stop and Slider

Find the top stop at the end of your zipper tape. Gently pry it off with pliers. Slide the old slider off carefully; if jammed, cut it away with nippers.

Step 2: Install the New Slider and Stop

Orient the new slider correctly — the “nose” should face outward. Feed the tape ends into the throats evenly. Move it up and down to confirm smooth alignment. Crimp a new top stop below the edge to lock it in place.

That’s it! Your zipper is back in working order. LenZip provides replacement sliders, stops, and zipper assemblies for coil, molded, and metal types.

Conclusion: Secure Quality with the Right Slider

Zippers may seem simple, but every reliable closure depends on a precisely engineered slider. A worn or damaged slider doesn’t have to end your product’s life — with the right tools and knowledge, you can repair it in minutes.

By understanding zipper slider parts, identifying your zipper’s type and gauge, and sourcing parts from LenZip, you can ensure consistent performance across every product line.

LenZip’s American-made zippers embody reliability, craftsmanship, and long-term value. From heavy-duty marine gear to fine apparel, our precision-engineered sliders keep your products functioning and your customers satisfied.

Learn more about zipper materials, coatings, and finishes at Zipper Materials & Finishes.

Frequently Asked Questions

What do the numbers and letters on a slider mean?

They represent the zipper’s gauge and type. For example, “5C” means a #5 coil slider. Always double-check with physical measurements.

Can I use sliders from different zipper types?

No. Sliders are engineered for specific tooth shapes. A metal slider won’t fit a molded or coil zipper.

Why does my zipper separate after closing?

The slider’s throats have widened from wear, reducing compression. Replacing the slider restores proper tension.

Does LenZip supply replacement parts?

Yes. LenZip manufactures U.S.-made replacement sliders and assemblies for apparel, industrial, and marine applications.