Among metal zippers, the base alloy defines far more than shine or color—it determines mechanical strength, long-term reliability, corrosion behavior, and tactile feel. For engineers designing rugged outdoor gear, fashion houses specifying luxury finishes, or OEMs building industrial uniforms, the difference between brass and aluminum translates into years of service life and product perception.

LenZip USA, a leading American zipper manufacturer, produces both brass and aluminum metal lines tested to meet demanding mechanical and environmental specifications. Their engineers study each metal’s unique advantages to help customers balance weight, cost, durability, and aesthetic goals.

Understanding Brass and Aluminum Zippers

Brass zippers are produced from an alloy of copper and zinc that offers an ideal mix of hardness, ductility, and corrosion resistance. The teeth are stamped or cast with tight tolerances to ensure precise interlocking and smooth slider travel—an essential factor for workwear, tactical equipment, and other heavy-duty uses. After forming, many brass zippers are electroplated or lacquer-finished to prevent oxidation and maintain their polished tone.

Aluminum zippers use lightweight alloys such as 6061 or 7075, which combine low density with respectable strength. Their teeth are usually extruded or stamped before being anodized for added surface hardness and corrosion control. While the oxide layer formed on raw aluminum offers some natural protection, additional coating is often required for humid or marine conditions.

Brass therefore delivers a dense, substantial feel with decades of wear potential, while aluminum brings modern brightness and minimal weight. More on available finishes can be found in Zipper Materials & Finishes.

Strength, Weight, and Load-Bearing

Mechanical Comparison

| Property | Brass Zipper Teeth | Aluminum Zipper Teeth |

|---|---|---|

| Tensile Strength | 350 – 500 MPa | 82 – 570 MPa (alloy dependent) |

| Density | ~8.4 g/cm³ | ~2.7 g/cm³ |

| Hardness | 60 – 180 HV | 45 – 95 HV |

| Durability | Excellent, work-hardening over time | Moderate; can wear under heavy load |

Because of its high tensile capacity and work-hardening nature, brass resists tooth deformation even after thousands of pull cycles, maintaining alignment through years of mechanical stress. It remains the metal of choice for military uniforms, industrial coveralls, motorcycle jackets, and reinforced backpacks.

Aluminum, while strong for its weight, is more susceptible to tooth bending when used in high-load garments or equipment. Its real advantage lies in lightweight applications—such as technical outerwear, athletic packs, and children’s clothing—where every gram saved improves comfort or reduces shipping cost. For quantitative strength testing, see Zipper Load Testing Explained.

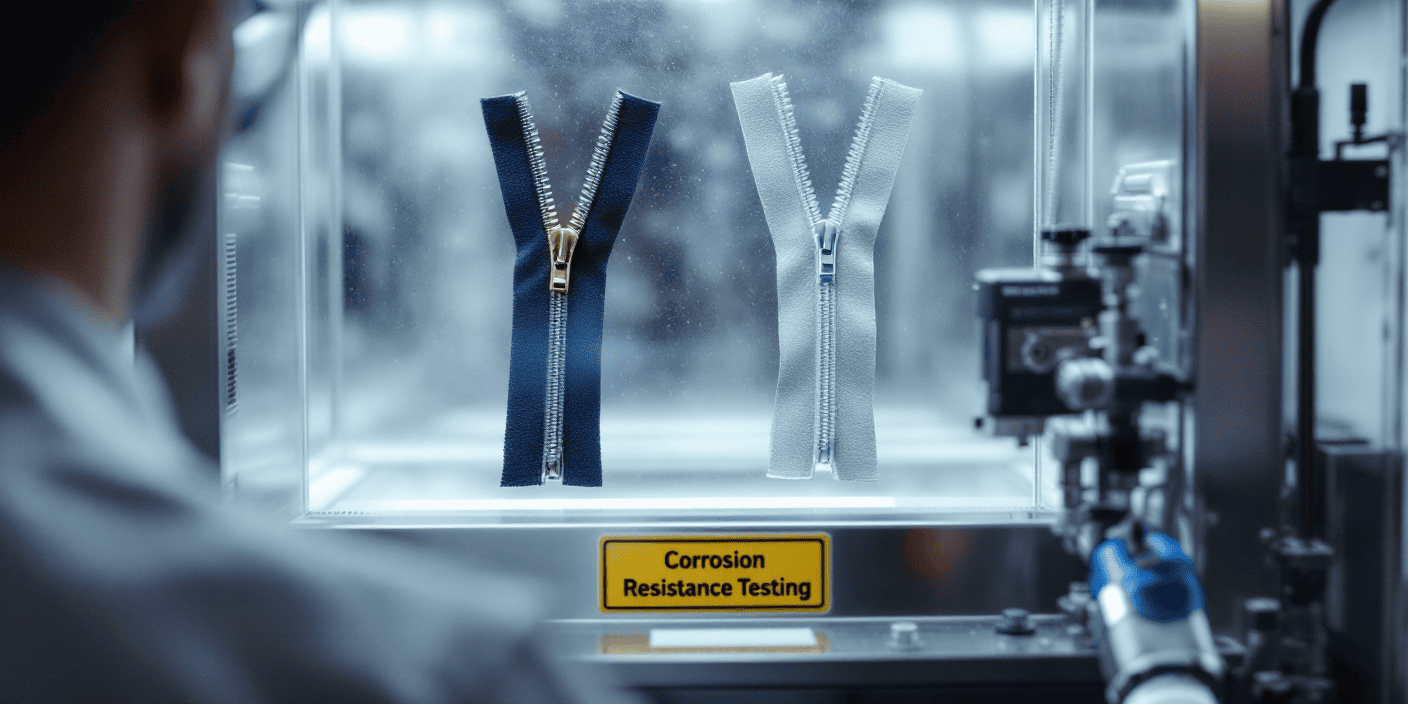

Corrosion Behavior in Marine and Outdoor Use

Brass performs exceptionally well in wet or salty environments because it forms a protective patina rather than rusting. This oxide layer shields the base alloy, allowing brass zippers to maintain smooth movement even after long exposure to moisture or salt-fog. Finishes such as nickel plating, black oxide, or antique brass enhance both corrosion resistance and aesthetic appeal. In marine fabrication, industrial curtains, and safety gear, brass zippers remain functional after years of cycles and cleaning.

Aluminum’s oxide behaves differently: the powdery coating that develops in humid or coastal conditions can cause sliders to seize and dull the metal’s appearance. Anodizing or painting helps delay this, but in harsh marine air, aluminum gradually loses its polish and tactile smoothness. For extended ocean or outdoor use, brass is consistently the superior performer. Further comparisons appear in Marine & Outdoor Zippers.

Aesthetic and Finish Possibilities

Metal zippers contribute as much to design identity as they do to function. Brass can be polished for a deep golden sheen, antiqued for a vintage look, or plated with nickel, gunmetal, or black chrome for modern appeal. The warmth of brass enhances leather goods, premium denim, and luggage, creating visual contrast and perceived value.

Aluminum lends itself to bright silver tones and color anodizing, giving designers freedom to integrate metallic hues into performance or fashion pieces. Its clean, minimalistic surface complements technical fabrics, lightweight jackets, and contemporary sportswear. For surface coating options, see Zipper Coatings & Finishes.

Application Selection and Engineering Context

Choosing between metals begins with intended environment and service demands. Heavy-duty garments, industrial uniforms, and motorcycle or tactical gear almost always rely on brass because its teeth can handle repetitive strain, exposure to oils, and laundering without failure. In contrast, aluminum is well suited to light jackets, running vests, and travel accessories, where low weight and visual brightness outweigh ultimate strength.

Environmental factors also drive material choice. For equipment exposed to chemical splashes or salt spray, brass’s corrosion stability makes it the safer investment. Products designed for single-season wear or fast-turn fashion benefit from aluminum’s lower cost and easier color customization. LenZip’s engineering team helps OEMs weigh these trade-offs in detail—see Choosing the Right Zipper.

Sizing and Tolerance in Metal Zippers

Metal zippers are graded by gauge—#3 for delicate garments through #10 and larger for extreme-duty applications. As gauge increases, the teeth become thicker and stronger. Large-tooth brass zippers are preferred for outerwear, duffels, and tents, providing reliable closure under stress. Proper sizing ensures not only strength but also ease of motion and aesthetic proportion. Reference details are available in Zipper Gauge & Chain Size Chart.

Manufacturing and Quality Control

At LenZip USA, each brass and aluminum zipper undergoes precision machining and in-line inspection to guarantee uniform tooth alignment, surface finish, and slider fit. Advanced vision systems verify that plating, pitch, and pull resistance meet ASTM and ISO requirements. This meticulous process ensures consistent smoothness and engagement even under high load.

Both brass and aluminum are recyclable, supporting responsible manufacturing. While brass production requires more energy per gram, its longer lifespan often offsets the environmental cost through decades of use. LenZip continues to refine eco-friendly plating baths and material recovery methods, part of its Eco-Engineered Zippers initiative.

Comparative Performance Summary

| Feature | Brass Zippers | Aluminum Zippers |

|---|---|---|

| Strength | High mechanical resilience | Moderate; lighter duty |

| Weight | Dense and heavy | Ultra-lightweight |

| Corrosion Resistance | Excellent; forms protective patina | Fair; oxidizes in humidity |

| Wear Resistance | Long-term durability | Can abrade under tension |

| Aesthetic Range | Polished, antique, or plated tones | Bright, matte, or color-anodized |

| Manufacturing Precision | High tolerance for industrial use | Optimized for mass fashion |

| Lifespan | Multi-year in harsh service | 1–3 years in moderate use |

| Environmental Impact | Recyclable; durable | Recyclable; low-energy refining |

Real-World Use Cases

In industrial coveralls, a #10 brass zipper can survive thousands of pulls through dust, oil, and high-temperature laundering without tooth distortion. By contrast, an aluminum zipper in the same setting would likely corrode or misalign within months.

In fashion design, brass conveys luxury and authenticity. Premium denim, leather jackets, and handbags often feature antique or black-nickel brass to complement rich textures. The tactile feel of brass teeth contributes to perceived product quality.

Lightweight rain jackets or single-season athletic packs, on the other hand, benefit from aluminum’s low weight and bright tone. For these goods, longevity expectations are shorter, and aluminum offers the right balance of function and economy.

Maintenance and Field Longevity

Brass requires minimal upkeep beyond occasional cleaning with a soft cloth or brush. A touch of wax or silicone lubricant restores effortless glide even after exposure to salt or dust. Tarnish can be polished away, revealing the original sheen while preserving corrosion protection.

Aluminum zippers should be kept dry whenever possible. Regular cleaning prevents oxide buildup that can hinder slider motion. Light polishing can remove early oxidation, but once pitting occurs, tooth strength diminishes. Proper storage and gentle operation help extend their service life.

Innovations in Metal Zipper Design

Ongoing research at LenZip focuses on enhanced coatings and performance features, including nanoceramic barriers for corrosion control, color-stable anodizing for branding, and compact slider geometries for sleeker fashion lines. New lockable and magnetic pulls improve security and accessibility in industrial and travel applications. These advancements demonstrate how traditional materials like brass and aluminum continue to evolve within modern manufacturing.

Sustainability and Circular Recovery

Both metals retain high scrap value and can be reintroduced into production with minimal degradation. Brass recycling yields copper and zinc for reuse in precision alloys, while aluminum recycling consumes only a fraction of the energy required for virgin production. LenZip encourages end-of-life disassembly of metal components to support closed-loop textile recycling, an approach further detailed in Repairable Zippers and Circular Design.

Conclusion

Brass and aluminum each have distinctive advantages shaped by their chemistry and intended purpose. Brass remains the benchmark for strength, corrosion resistance, and timeless appeal, making it indispensable in industrial, marine, and premium fashion markets. Aluminum’s lightness and versatility lend it to fast-moving apparel and accessories where agility and modern styling matter more than long-term endurance.

For consultation or to request technical specifications, visit LenZip’s Request a Quote or explore the Products section for custom metal zippers tailored to your application.

Frequently Asked Questions

Are brass zippers stronger than aluminum?

Yes. Brass zippers have higher tensile and wear strength, maintaining reliable function under heavy loads where aluminum may deform.

Which metal resists corrosion better?

Brass forms a stable protective patina and is preferred for marine or outdoor use, whereas aluminum requires coatings to prevent oxidation.

Do aluminum zippers rust?

Aluminum does not rust like steel but can corrode through white oxidation, especially in salty or humid conditions.

Which type is better for marine gear or outdoor tents?

Brass is superior for wet, high-salinity environments because it remains functional and visually stable over time.

Does LenZip manufacture both metals in the USA?

Yes. LenZip engineers and tests both brass and aluminum zipper lines domestically to ASTM and ISO standards for strength, corrosion, and longevity.