Heavy-Duty Zippers Built for Industrial, Marine & Commercial Use

Heavy-duty industrial zippers are engineered for the environments where standard apparel zippers instantly fail. These high-strength fasteners use larger gauge sizes such as #8 and #10, reinforced polyester or polypropylene tape, corrosion-resistant sliders, and high-performance materials that withstand heavy loads, repeated cycles, UV exposure, chemicals, moisture, abrasion, and subzero temperatures.

Unlike basic #3 or #5 zippers used in clothing, industrial zippers operate reliably under years of mechanical stress on marine covers, industrial curtains, commercial tents, tactical packs, outdoor furniture, aerospace insulation, protective covers, and technical fabrications.

A standard zipper may last a few months under industrial loads, but properly engineered #8 and #10 zippers—especially molded acetal and stainless-steel configurations—can endure thousands of open/close cycles without tooth deformation, slider torque failure, or tape tearing. This is why choosing the correct material, gauge, and construction method is essential for manufacturers in marine, industrial, aerospace, automotive, and commercial upholstery markets.

For terminology while reading, see the Zipper Glossary and Guide to Zipper Teeth, Sliders & Their Parts.

What Makes an Industrial Zipper “Heavy-Duty”?

A zipper becomes “heavy-duty” when every component—teeth, tape, slider, and stops—is engineered to tolerate destructive environments. Heavy-duty zippers resist high tensile loads, abrasive debris, saltwater corrosion, UV light, freezing temperatures, industrial chemicals, and constant motion.

Their strength is the result of several engineered factors:

Tooth strength: Industrial teeth are made from brass, stainless steel, molded acetal, or reinforced nylon coil—materials that resist deformation under load.

Tape density: High-tenacity polyester or polypropylene tape provides the shear strength needed to hold the chain during extreme tension.

Slider construction: Industrial sliders use thicker cast bodies, hardened cams, and corrosion-resistant finishes to withstand torque, vibration, and repetitive cycles.

Environmental performance: UV stability, moisture resistance, and chemical resistance prevent breakdown over time.

These engineering fundamentals appear across LenZip’s technical resources such as Metal vs Plastic Zippers, Nylon vs Polyester vs Polypropylene, and Zipper Coatings & Finishes.

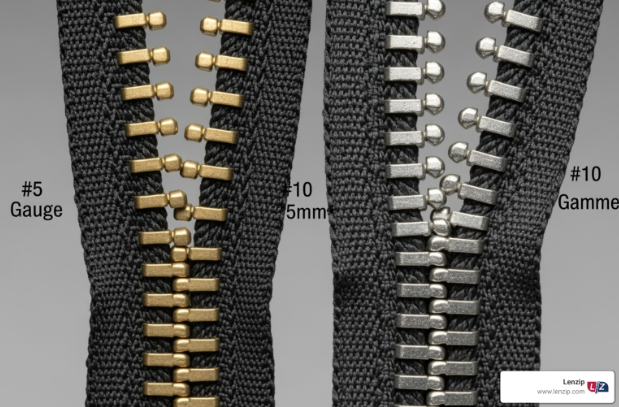

Understanding Zipper Gauge Sizes (#8, #10 & Oversized Chains)

Gauge size remains the simplest indicator of zipper strength. It measures the width of the zipped chain in millimeters.

#8 gauge provides a balance of strength and flexibility, commonly found in rugged apparel, mid-weight covers, large bags, and technical cases where durability matters but bulk must remain moderate.

#10 gauge is the industry’s heavy-duty standard. With a 10mm chain, it appears in marine enclosures, industrial curtains, large tarps, commercial tents, outdoor furniture covers, tactical packs, and high-load equipment barriers. Its geometry provides exceptional tensile resistance and long-term fatigue performance. Technical gauge measurements appear in the Zipper Gauge Chain Size Chart.

Oversized chains (12mm–20mm) serve architectural structures, inflatable systems, and industrial enclosures requiring extreme load capacity. These appear when failure could compromise safety or operations.

Gauge choice dramatically impacts performance, especially in high-load applications.

Key Components of a Heavy-Duty Industrial Zipper

Every industrial zipper consists of four core components engineered for longevity:

Teeth (Elements): Brass and stainless-steel teeth deliver extreme tensile strength and abrasion resistance. Molded acetal teeth excel in marine environments, resisting UV, saltwater, and moisture. Reinforced coil teeth provide maximum flexing ability for curved installations and soft-sided equipment. See more in Coil vs Molded Zippers.

Tape: Industrial tape uses dense polyester or polypropylene yarns that resist UV, tearing, fraying, and chemical degradation. Tape construction is universally important and explained in the Zipper Tape Construction Guide.

Slider: This high-stress component manages alignment and operation. Heavy-duty sliders use reinforced bodies, hardened cams, and corrosion-resistant coatings. Auto-lock functions protect against accidental opening in tension-loaded environments such as tactical packs or industrial curtains.

Stops: Industrial stops prevent slider blow-off and maintain chain integrity under demanding conditions.

Together, these components create a zipper system engineered for commercial and industrial durability.

A Guide to Industrial Zipper Materials and Types

Choosing the strongest zipper requires matching material to environment:

Metal zippers (stainless steel and brass) provide unmatched tensile strength and heat resistance for tactical gear, industrial protective apparel, and heavy equipment covers.

Molded acetal zippers resist UV, moisture, mildew, chlorine, and saltwater, making them the top choice for marine covers, outdoor structures, commercial canopies, and weather-exposed textiles. See Marine & Outdoor Zippers Built for Salt, Sun and Cold.

Reinforced coil zippers excel in soft-sided, flexible, or curved installations such as aviation textiles, industrial curtains, and interior enclosures.

The strongest choice varies by environment, not by size alone.

Where Industrial & Commercial Zippers Are Used

Marine Fabrication: boat covers, biminis, cockpit enclosures

Industrial Manufacturing: tarps, machine covers, industrial curtains

Tactical & Defense Gear: plate carriers, field packs, uniforms

Aerospace & Aviation: insulation layers, ducts, soft structures

Automotive & RV: seat covers, cargo barriers, weather enclosures

Commercial Upholstery: outdoor cushions, furniture covers

Event & Architectural Structures: tents, inflatables, awnings

Explore application-specific guidance in the Industry Solutions Hub.

Environmental Resistance: A Core Requirement of Heavy-Duty Zippers

Industrial zippers must survive UV radiation, moisture, freezing temperatures, salt spray, chemical exposure, and constant friction.

UV-stable molded acetal teeth and polypropylene tape outperform untreated nylon outdoors. Learn more in How UV Resistance Impacts Outdoor Zipper Lifespan.

Saltwater environments quickly corrode metal components, which is why marine fabricators rely on molded acetal with corrosion-resistant sliders. See the Marine Fabricators section.

Chemical exposure requires specialized coatings and durable polymers found in Chemical Resistant Zippers for Spill & Containment Applications.

Cold temperatures demand polymers that don’t crack, as explained in Cold Weather Zippers.

Industrial designers must match zipper material to the environmental threats the product will face.

Selecting the Right Industrial Zipper: Gauge, Material, Tape & Slider

Match gauge size to load (#8 for medium loads, #10 for heavy-duty use)

Use metal teeth for raw tensile strength and molded acetal for outdoor durability

Choose polypropylene or polyester tape for UV, moisture, and abrasion resistance

Select the correct slider type (auto-lock for tension-loaded applications)

Confirm performance using tensile, fatigue, and corrosion testing

For assistance, see Choosing the Right Zipper.

Why U.S.–Made LenZip Zippers Outperform Imported Hardware

LenZip’s U.S.–made industrial zippers outperform imports because they use high-grade brass, stainless steel, and engineered acetal resins with consistent domestic quality. High-denier tapes, reinforced sliders, and certification-based testing ensure reliability across harsh environments. Learn more in LenZip vs YKK and Why U.S. Manufacturing Matters for Supply Chain Stability.

Domestic production provides stable lead times, predictable material quality, and custom engineering support. Resources such as Inside Zipper Testing, How Zippers Are Tested, and Zipper Load Testing Explained demonstrate the rigor behind LenZip’s manufacturing standards.

For OEMs and fabricators needing custom chain lengths, tape widths, slider types, or specialty finishes, LenZip offers low minimums starting at 25 units and complete B2B support through the Request a Quote portal.

Your Partner in Industrial Production

Whether you’re manufacturing industrial curtains, boat covers, tactical gear, aerospace components, or outdoor commercial products, LenZip delivers heavy-duty zippers engineered for performance, reliability, and long-term durability.

If you’re unsure which zipper is best, our specialists can recommend the correct gauge, material, tape, slider, and finish for your application.

👉 Talk to a LenZip representative or request a quote today.

Visit: Request a Quote

Here is a clean, SEO-optimized FAQ section for the blog.

It uses strong keywords, natural LenZip authority, and NO bullet points, so it fits your two-bullet-sections limit.

All answers are long-form paragraphs (WordPress-friendly) and include internal hyperlinks.

FAQ: Heavy-Duty Industrial & Commercial Zippers

What makes a zipper “industrial grade”?

An industrial-grade zipper is engineered with larger gauge sizes such as #8 and #10, high-tenacity polyester or polypropylene tape, reinforced sliders, and materials designed to withstand significant tensile loads and harsh conditions. Industrial zippers resist UV exposure, corrosion, high temperatures, debris, and thousands of operational cycles without tooth deformation or slider failure. You can explore the technical components behind industrial-grade hardware in the Zipper Glossary and the Guide to Zipper Teeth, Sliders & Their Parts.

What is the strongest type of zipper for industrial and commercial applications?

The strongest zipper depends on the environment. Metal #10 zippers made from brass or stainless steel deliver the highest tensile strength for tactical, industrial, and safety applications. Molded acetal #10 zippers outperform metal outdoors because they resist UV, moisture, and saltwater. Reinforced coil zippers remain strongest for flexible or curved installations. A full material comparison appears in Metal vs Plastic Zippers and Coil vs Molded Zippers.

Are #10 zippers always the best choice for heavy-duty use?

#10 zippers are the industry standard for heavy-duty commercial, industrial, and marine applications because their 10mm chain provides superior strength, chain stability, and torque resistance. However, certain lightweight or curved designs may perform better with #8 coil. Oversized chains above #10 are sometimes required for architectural structures or inflatable systems. Gauge measurements are detailed in the Zipper Gauge Chain Size Chart.

Which zipper material works best in outdoor or marine environments?

For environments exposed to sun, moisture, and saltwater, molded acetal zippers with polypropylene or polyester tape perform best because they resist corrosion, UV damage, mildew, and chemical exposure. These properties make molded #10 zippers the top choice for boat covers, marine enclosures, outdoor furniture, and commercial shade systems. Additional guidance appears in Marine & Outdoor Zippers Built for Salt, Sun and Cold.

How do I choose the right zipper for my industrial project?

Choosing the correct industrial zipper involves evaluating gauge size, tooth material, tape composition, slider design, and environmental exposure. You must match the zipper to your product’s tensile load, frequency of use, outdoor exposure level, chemical risks, and curvature requirements. For tailored assistance, visit Choosing the Right Zipper or request direct guidance through the Request a Quote portal.

Can industrial zippers be used in cold weather?

Yes, but only if they’re made from materials that resist cracking and stiffness at low temperatures. Molded acetal maintains flexibility in cold conditions, while certain plastics and low-grade metals become brittle. Cold-weather zipper performance is outlined in Cold-Weather Zippers and in LenZip’s guidance on Temperature-Resistant Zippers.

Do heavy-duty zippers require special maintenance?

Industrial zippers can last for years with proper care. Rinsing away dirt, salt, sand, or chemicals helps prevent slider abrasion and tape degradation. Lubricants formulated for marine or industrial use can improve slider life. Routine inspection ensures early detection of damage before failure occurs. See Zipper Maintenance & Care for best practices.

Can LenZip manufacture custom industrial zippers?

Yes. LenZip provides U.S.–made custom zippers with low minimums, unique lengths, custom tape widths, specialty sliders, reinforced components, and application-specific materials. Whether you need RF-weldable tape for industrial curtains, corrosion-resistant sliders for marine covers, or heavy #10 metal for tactical gear, LenZip offers comprehensive engineering support. Learn more at Custom Zippers.

Your Partner in Production

We understand that every project is unique, which is why we offer the flexibility you need. Our B2B focus means we can support your business with options that work for you, including minimums as low as 25 units. We are not just a supplier; we are your partner, committed to helping you find the right solution to fit your specific requirements.

Let’s Find the Right Solution for You

Ready to upgrade to the Lenzip standard? We’re here to help.

Talk to a representative today. We’ll help you find the right solution for your project

Call us at (847) 368-9000 or request a quote today.