Choosing the Right Zipper System for OEM Performance

In manufacturing, the right zipper is more than a fastener—it’s a structural component that determines ease of assembly, reliability, and longevity. Whether you’re engineering marine covers, industrial enclosures, or protective apparel, one decision shapes performance from day one: choosing between a continuous chain zipper and a finished zipper assembly.

At LenZip, a U.S.-owned custom zipper manufacturer, engineers guide OEMs through this decision daily. Each zipper configuration—continuous or finished—offers unique benefits for cost efficiency, customization, and long-term durability. Understanding where and when to use each ensures every closure performs to spec, on time, and for the lifetime of your product.

What Is a Continuous Chain Zipper?

A continuous chain zipper is exactly what the name implies: zipper chain sold by the roll or cut-to-length, without pre-attached sliders, stops, or starter boxes. This style offers complete design flexibility, allowing fabricators to cut and assemble zippers of any length for custom or oversized products.

Because there are no pre-defined endpoints, continuous chain is ideal for long runs, curved seams, or modular structures where precise measurements vary from project to project. It’s widely used in marine canvas fabrication, industrial covers, tents, awnings, architectural textiles, and upholstery.

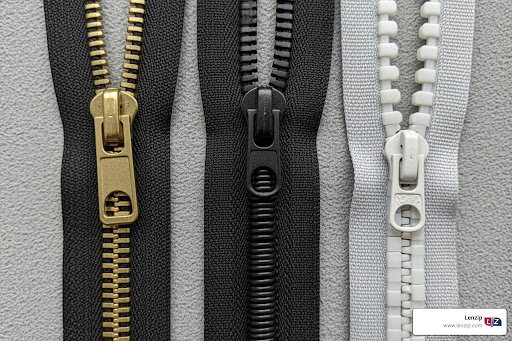

LenZip supplies continuous chain in coil, molded-tooth, and metal varieties—each tested under ASTM D2061 for tensile strength and D2051 for slider performance. Coil chain provides flexibility for curved applications, while molded tooth options deliver high abrasion resistance in outdoor and marine environments. The result is OEM-grade zipper chain that can be configured for virtually any purpose, all manufactured and tested in the U.S.

What Is a Finished Zipper?

A finished zipper arrives fully assembled—complete with slider, top and bottom stops, and sometimes a starter box or pin for separating styles. It’s “ready to install,” saving manufacturers labor time and ensuring perfect alignment right out of the box.

Finished zippers come in two main types:

- Separating zippers, often used in jackets, PPE, marine enclosures, and removable panels.

- Non-separating zippers, used in bags, cushions, pouches, and industrial cases where both ends remain anchored.

Unlike continuous chain, finished zippers have fixed lengths determined by gauge and model. They excel in mass-production environments, uniform designs, and applications requiring consistent size and closure strength. LenZip produces both separating and non-separating finished zippers, customized with locking sliders, double pulls, or corrosion-resistant coatings to meet specific OEM requirements.

Continuous Chain vs. Finished Zippers – Key Differences

Choosing between continuous chain and finished zippers comes down to balancing flexibility, assembly, and production efficiency.

- Customization & Length: Continuous chain can be cut to any size for large or irregular applications; finished zippers come in fixed, factory lengths.

- Assembly: Continuous chain requires adding sliders and stops; finished zippers are pre-assembled and ready to sew in.

- Application Fit: Continuous suits industrial covers, canopies, and marine enclosures; finished fits garments, bags, and smaller sewn goods.

- Efficiency: Continuous chain reduces waste and inventory complexity; finished zippers save labor time and minimize assembly errors.

- Durability: Both can achieve heavy-duty performance when built with LenZip’s engineered components and tested to ASTM standards.

Ultimately, the choice depends on whether your production needs flexibility and scalability—or precision and speed of assembly.

Matching Applications to Zipper Type

Continuous Chain – For Large or Variable Dimensions

Continuous chain is preferred in marine, industrial, and architectural textile manufacturing because of its adaptability. Fabricators can cut zippers to exact field measurements, curve them around corners, or run them along multi-panel enclosures. It’s especially effective in boat covers, canopies, RV awnings, tent systems, and equipment enclosures that demand long, uninterrupted runs.

LenZip’s continuous coil and molded-tooth zippers resist UV degradation, corrosion, and abrasion—critical for outdoor environments where materials must endure years of exposure. OEMs also benefit from reduced inventory, ordering bulk rolls rather than stocking dozens of different lengths.

Finished Zippers – For Ready-to-Install Efficiency

Finished zippers shine in uniform, repeatable production, such as jackets, bags, cushions, tool cases, and PPE uniforms. Each unit arrives pre-assembled with perfect alignment, saving assembly time and ensuring consistent closure performance.

They’re ideal for OEMs seeking turnkey integration—particularly in apparel or consumer goods where visual symmetry and clean end finishing matter. LenZip offers finished zippers engineered for specific applications: fire-resistant gear (NFPA 2112 compliant), weatherproof outdoor wear, and industrial uniforms requiring high tensile strength.

Manufacturing and Compatibility Considerations

The distinction between continuous chain and finished zippers extends beyond assembly—it also affects slider compatibility, gauge selection, and quality control.

For continuous chain, selecting the correct slider type is critical. Coil, molded, and metal chains each demand a matching slider geometry and gauge (#5, #10, #15, etc.). LenZip’s engineering team helps OEMs specify compatible components, including locking vs. non-locking sliders, long pulls, and corrosion-resistant metals for marine environments.

Finished zippers simplify compatibility since sliders and stops are factory installed. However, when precision or environmental conditions require custom coatings or tape materials, LenZip provides U.S.-made, fully traceable assemblies tested for tensile, fatigue, and corrosion resistance under ASTM and MIL-SPEC protocols.

For large production runs, LenZip’s U.S.-based manufacturing shortens lead times while guaranteeing consistent gauge alignment, chain tension, and end-stop integrity—performance attributes that protect both your product and your brand reputation.

Why OEMs Choose LenZip for Continuous and Finished Zippers

OEMs across industries rely on LenZip for engineered zipper solutions that balance performance, cost, and compliance. Every chain or assembly is tested, logged, and certified within LenZip’s domestic facility, giving customers verifiable performance data and complete batch traceability.

By manufacturing both continuous chain and finished zippers in-house, LenZip eliminates compatibility issues and streamlines supply chains. Engineers can specify the exact gauge, material, and finish needed—whether it’s a continuous molded chain for a marine enclosure or a finished coil zipper for protective clothing.

OEM partners also gain access to technical collaboration and fast sample turnaround, ensuring each zipper system aligns with application-specific tolerances, environmental exposure, and regulatory standards.

Conclusion

Both continuous chain and finished zippers play vital roles in engineered soft goods and technical textiles. Continuous chain offers flexibility and scalability for custom dimensions and large fabric structures; finished zippers deliver precision and convenience for standardized assemblies and apparel production.

For OEMs, the best solution often depends on the balance between manufacturing speed, customization, and product durability. By partnering with LenZip—a U.S.-owned zipper manufacturer with in-house testing, rapid prototyping, and unmatched quality control—you gain both options, engineered to perform under any condition.

To determine which configuration best suits your next project, contact LenZip’s engineering team for a consultation or prototype sample.

FAQ: Continuous Chain vs. Finished Zippers

What is the main difference between continuous and finished zippers?

Continuous chain zippers are supplied without stops or sliders, allowing custom length and configuration. Finished zippers arrive fully assembled, ready to install.

Can a continuous chain be converted into a finished zipper?

Yes. By adding compatible sliders and end stops, a continuous zipper can be assembled into a finished zipper system, often done for oversized or custom projects.

Which zipper type is best for marine and outdoor covers?

Continuous molded-tooth or coil zippers perform best in marine and outdoor environments because they can be cut to exact lengths and sealed into long, weather-resistant seams.

Are continuous zippers more cost-effective for large-scale production?

For large enclosures or modular designs, continuous chain is typically more efficient—it minimizes inventory complexity and allows one bulk order to serve multiple sizes.

What standards ensure zipper quality and performance?

LenZip tests all zippers under ASTM D2061 (tensile), ASTM B117 (corrosion), and MIL-SPEC performance standards for verified OEM durability.

Does LenZip manufacture both continuous and finished zippers in-house?

Yes. All continuous chain and finished zipper assemblies are designed, produced, and tested in LenZip’s U.S. facility, ensuring consistent quality and traceability from chain to final assembly.