Unlocking Creativity:

Finding the Perfect Custom Zipper Manufacturer

Unlock design potential with custom zippers. Learn types, materials, and how to choose the best custom zipper manufacturer.

Finding the Perfect Custom Zipper Manufacturer

A custom zipper manufacturer creates specialized fasteners tailored to your exact specifications, materials, and branding needs. Choosing the right OEM zipper supplier is critical, as the industry has long struggled with what one American manufacturer calls “bait and switch pricing, unfulfilled lead times, and varying quality.”

Key criteria for selecting a manufacturing partner include:

Experience: 15+ years in zipper manufacturing

Capabilities: In-house design, engineering, and dyeing

Quality: ISO certifications and industry-specific compliance

Flexibility: No minimum order quantities (MOQs)

Delivery: Reliable lead times (samples in 5–7 days, production in 3–5 weeks)

Custom zippers are more than functional components—they’re design elements that elevate products across industries like automotive, marine, aerospace, furniture, and apparel. Whether you need fire-retardant zippers for military gear or branded pullers for luxury goods, the right manufacturer becomes an extension of your team.

This guide covers everything from understanding zipper types to navigating the ordering process with a custom zipper manufacturer.

The World of Custom Zippers: Types and Materials

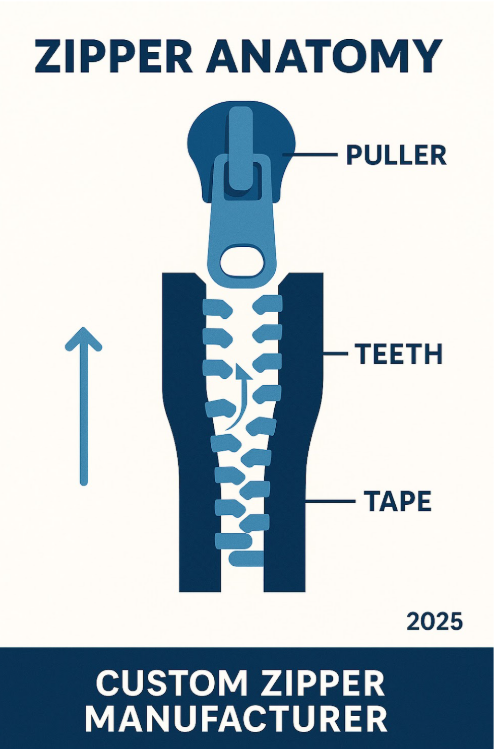

Imagine the satisfying glide of a perfectly crafted zipper. That’s the difference quality makes. When working with a custom zipper manufacturer such as LenZip (https://lenzip.com/), understanding your options is key to creating products that shine. Every zipper has a slider, puller, teeth, and tape—but the materials and customization options are what make them unique.

Coil Zippers: Made from a continuous spiral of nylon, these zippers are flexible and durable. They bend without breaking, making them ideal for backpacks and outdoor gear. They are available in sizes from N3 to N10.

For more insight on construction, visit Guide to Zipper Teeth, Sliders, and Their Parts (https://lenzip.com/guide-to-zipper-teeth-sliders-and-their-parts/).

A Closer Look at Zipper Types

Each zipper type offers unique strengths, and choosing the right one is critical for your product’s performance.

Metal Zippers: With individually attached teeth, these zippers offer a classic, premium feel and can handle serious abuse. You’ll find them on quality jeans, work uniforms, and luxury leather goods.

Plastic Molded Zippers: Often called Vislon zippers, these offer a balance of durability and light weight. The teeth are injection-molded onto the tape, creating a smooth, corrosion-resistant operation perfect for sportswear and outdoor gear.

Invisible Zippers: The teeth are hidden beneath the tape, creating a seamless look favored by fashion designers for dresses and upholstery.

Water-Resistant Zippers: Featuring a reverse coil construction and TPU coating, these create a reliable seal against moisture for marine gear, hazmat suits, and more. (LenZip uses the term water-resistant to ensure accuracy.)

Fire Retardant Zippers: Built with specialized materials like NOMEX® tape and treated with fire-resistant finishes, these meet strict safety standards for military, oil industry, and firefighting equipment.

Explore what’s possible for your project by checking out more info about our Custom Zipper Products (https://lenzip.com/products/).

Understanding Zipper Materials and Finishes

Material and finish choices affect your zipper’s look, performance, and longevity. For deeper insights, see Zipper Materials & Finishes (https://lenzip.com/zipper-materials-finishes/).

Metal Options: Choose from brass for a classic golden luster, aluminum for lightweight durability, or zinc for versatile performance.

Plastic Options: Polyacetal and nylon excel where flexibility and resistance to moisture and chemicals are needed.

Tape Materials: Polyester tape offers reliable durability, cotton provides a natural feel, and NOMEX® brings fire-resistant properties for safety gear.

Finishes: Transform the look of metal zippers with finishes like antique brass for vintage appeal, nickel for modern sophistication, or gold for a touch of luxury.

Custom Colors: This is where a top custom zipper manufacturer excels. With access to over 600 colors and in-house dye facilities, perfect color matching to any Pantone shade becomes a reality, ensuring your zippers integrate seamlessly with your brand’s vision.

For more detailed explanations, see the Zipper Terminology Guide (https://lenzip.com/zipper-terms-you-should-know/).

Why Go Custom? Applications and Brand Benefits

Imagine two identical jackets. One has a generic zipper, while the other has a custom zipper that perfectly matches the fabric, with a logo puller that feels just right. That’s the power of custom—and it’s why smart businesses choose a custom zipper manufacturer like LenZip (https://lenzip.com/).

Custom zippers do more than open and close; they become part of your brand’s identity and your customer’s experience. It’s an investment in a competitive advantage.

Enhancing Your Product’s Design and Functionality

Brand Differentiation: A distinctive zipper can be the detail that makes a customer choose your product. It makes your brand memorable.

Custom Logo Pullers: These small canvases can feature your logo or unique shapes, acting as a miniature advertisement that improves the user experience. Many manufacturers offer free personalized puller designs.

Perfect Color Matching: In-house dye facilities allow for exact color matches, making your product look cohesive and professionally designed.

Improved User Experience: A smooth, reliable zipper eliminates frustrating snags and catches, associating that quality with your brand.

Durability for Specific Uses: Customization lets you build in the exact strength and resilience your product requires, whether for industrial washing or extreme temperatures.

Aesthetic Appeal: The look, feel, and even the sound of a well-designed zipper contribute to the perceived quality and value of your entire product.

Industries That Rely on Custom Zippers

Specialized zippers are essential in many industries:

Fashion & Apparel: Zippers become design elements, allowing for creative expression that can transform a garment.

Bags & Luggage: These products need durable closures that can handle weight and frequent, rough use.

Outdoor & Sporting Goods: Lightweight nylon and water-resistant zippers are critical for performance and safety in harsh conditions.

Military & Tactical Gear: Zippers must meet strict military specifications for reliability in extreme environments where lives may depend on them.

Automotive & Marine: These applications require zippers that resist temperature extremes, moisture, and UV exposure. Learn more in Why Zipper Quality Matters in Automotive Interiors (https://lenzip.com/why-zipper-quality-matters-in-automotive-interiors/).

Aerospace: Components must meet the most demanding standards for reliability and performance.

Furniture & Upholstery: Zippers allow for removable covers, blending seamlessly with fabric while providing easy access.

Medical Equipment: Zippers must meet strict hygiene standards while providing reliable operation for patient clothing or equipment covers.

How to Choose the Right Custom Zipper Manufacturer

Choosing the right custom zipper manufacturer is about finding a reliable partner who understands your vision and can execute it with precision. It’s a decision that can impact your entire production timeline.

When vetting partners, look beyond presentations and dig into their core capabilities, quality processes, and reliability.

At LenZip (https://lenzip.com/), we believe in transparency. Here’s what truly matters when evaluating a custom zipper manufacturer:

Manufacturing Experience: With 80 years in business, our extensive history proves our deep understanding of zipper manufacturing and our commitment to quality. See History of the Zipper (https://lenzip.com/history-of-the-zipper/).

In-house Capabilities: A true manufacturer handles design, engineering, prototyping, and production under one roof. Our comprehensive services ensure your requirements are met with precision.

Material Quality: We prioritize sourcing high-grade materials, ensuring every component meets stringent standards for durability and performance.

On-Time Delivery: We pride ourselves on our consistent delivery record. Our integrated distribution process keeps your projects on track.

Integrity and Communication: As dedicated American craftsmen, we stand apart with clear, honest communication, avoiding the “bait and switch pricing” common in the industry.

American Craftsmanship: Our heritage and skilled workforce contribute to a level of quality and reliability synonymous with North American production.

To learn more about our journey and values, visit About Us (https://lenzip.com/about-us/).

Understanding Quality Standards and Certifications

Certifications are independent validations of a manufacturer’s commitment to quality, safety, and ethical practices.

ISO 9001: The gold standard for quality management systems. Learn more at ISO 9001 Quality Management (https://www.iso.org/iso-9001-quality-management.html).

Oeko-Tex Standard 100: Guarantees that textiles, including zipper tapes, are free from harmful substances.

GRS (Global Recycled Standard): Verifies recycled content in products and responsible social practices.

BSCI (Business Social Compliance Initiative): Ensures ethical labor standards.

Military Specifications (Mil-spec): Crucial for defense or public safety products.

LenZip adheres to these standards through its Zipper Testing Standards (https://lenzip.com/zipper-testing-standards/) and Zipper Coatings & Finishes (https://lenzip.com/zipper-coatings-and-finishes/) protocols, ensuring every zipper meets or exceeds ASTM D2061 testing requirements (ASTM D2061 Standard – https://www.astm.org/d2061-07r21.html).

Navigating MOQs, Lead Times, and Pricing with a Custom Zipper Manufacturer

Minimum Order Quantity (MOQ): Many manufacturers impose MOQs, which can be a barrier. LenZip (https://lenzip.com/) proudly offers no minimum order quantity on many custom solutions.

Lead Times: Samples in as few as 5 days, bulk in 5–7 days, and complex orders in 10–15 days or up to 3–5 weeks.

Pricing Factors: Influenced by zipper type, material, length, color, and puller design. Request a Quote (https://lenzip.com/request-a-quote/) to receive transparent pricing in less than 24 hours.

The Custom Zipper Ordering and Manufacturing Process

Watching your custom zipper come to life is rewarding when working with the right manufacturing partner.

From Concept to Creation: A Step-by-Step Guide

Initial Consultation → Design & Engineering → Prototyping & Sampling → Mass Production → Quality Control → Shipping & Logistics.

Learn more about Custom-Fit Zippers (https://lenzip.com/custom-fit-demystifying-cut-to-length-zippers/) for specialized projects.

The Role of Sustainability in Modern Zipper Manufacturing

Sustainability is key to modern zipper production. LenZip (https://lenzip.com/) has developed recycled zippers using RPET from plastic bottles, aligning with GRS-certified standards and eco-friendly OEKO-TEX® dyes.

We also research biodegradable materials like PLA and use precision dyeing processes to minimize water waste. This aligns with responsible production as verified under ISO 14001 environmental management standards (https://www.iso.org/iso-14001-environmental-management.html).

What to Expect from Your Custom Zipper Manufacturer

Working with a leading custom zipper manufacturer should feel like gaining a new team member.

Innovation: LenZip’s 40+ patented technologies deliver real-world solutions.

R&D Capabilities: Constantly pushing new material innovations.

One-Stop Service: Buckles, tags, and hardware for full OEM zipper systems.

Integrated Supply Chain: From raw material to final assembly—ensuring quality and no MOQs.

Technical Support: Dedicated design advice and post-delivery assistance.

Conclusion

Choosing the right custom zipper manufacturer is about finding a partner who understands your vision and can deliver precision. With over 80 years of American craftsmanship, LenZip Manufacturing (https://lenzip.com/) provides reliability, transparency, and genuine collaboration for OEMs and designers alike.

Whether you need fire-retardant, water-resistant, or color-matched zippers, LenZip’s engineers will help you achieve perfection—on time and on budget.

We invite you to experience the difference. Explore Resources (https://lenzip.com/resources/) to learn more.

Frequently Asked Questions about Custom Zippers

How long does it take to get custom zippers?

Samples: 5 days. Bulk: 5–7 days (up to 3–5 weeks for complex builds).

What information do I need for a quote?

Type, length, color, material, quantity, and intended use.

Can I get zippers in any color?

Yes. LenZip offers over 600+ colors and custom Pantone matching through Zipper Materials & Finishes (https://lenzip.com/zipper-materials-finishes/).

Need more answers? Visit FAQ (https://lenzip.com/faq/).