From Plastic to Brass:

Finding Your Perfect Zipper Manufacturer

Choose the best plastic zipper manufacturer. Explore types, quality, and customization for your next project.

Finding the right plastic zipper manufacturer is crucial for businesses across industries, from automotive and marine to apparel and aerospace. The global plastic zipper market was valued at USD 1.5 billion in 2022 and is projected to reach USD 2.3 billion by 2030, growing at 5.5% annually.

The humble zipper may seem simple, but choosing the wrong manufacturer can lead to quality issues, delivery delays, and hidden costs that impact your entire production line. With plastic zippers accounting for a significant share of the overall zipper market, partnering with a reliable manufacturer isn’t just important—it’s essential for your business success.

When evaluating manufacturers, look for a partner with decades of experience, a commitment to US-based manufacturing, and a reputation for excellence in commercial and industrial applications. Key factors to consider include minimum order quantities (typically 5,000 pieces per color), lead times (ranging from 3-15 days for bulk orders), quality certifications like ISO 9001, and extensive customization capabilities.

A Guide to Plastic Zipper Types and Materials

The world of plastic zippers is diverse, with each type engineered for specific applications. Understanding these differences will help you make the perfect choice for your product. Plastic zippers are a top choice across countless industries, found in apparel, luggage, and outdoor gear. Their lightweight nature, corrosion resistance, and vast color possibilities make them incredibly versatile. More info about our products.

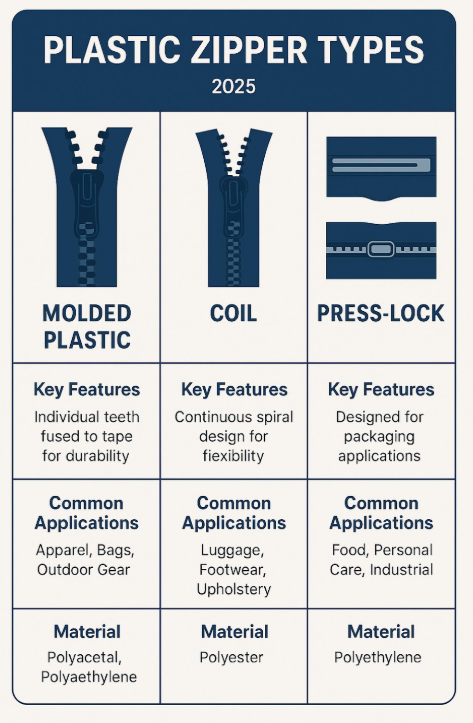

Types of Plastic Zippers

Let’s explore the three main types you’ll encounter when working with a plastic zipper manufacturer:

Molded Plastic Zippers are the workhorses of the zipper world. Often called “Delrin zippers,” these feature individual teeth fused directly to tape through injection molding. This creates an incredibly strong bond that can handle serious stress, making them ideal for jackets, coats, luggage, workwear, and outdoor gear like tents and sleeping bags.

Coil Zippers use a continuous polyester or nylon coil sewn onto the tape. This creates a smoother, more flexible zipper that’s perfect for less bulky applications. Concealed zippers are a popular variation, hiding the coil behind the tape for an almost invisible finish. You’ll find coil zippers in dresses, skirts, casual pants, handbags, and backpacks.

Press-Lock Zippers skip the traditional slider, using interlocking plastic profiles that snap together. They are simple, effective, and designed for packaging applications, such as resealable food or clothing bags and child-resistant packaging.

Common Materials Used in Production

The material choice is critical to a zipper’s performance. Modern manufacturers offer several impressive options:

Acetal Resin (POM) is the champion of zipper materials. This engineering plastic offers exceptional durability and strength, resisting chemicals and extreme temperatures. When you need a zipper that simply won’t quit, acetal resin delivers.

Polyester brings incredible versatility and color options. It holds dye beautifully, offering designers unlimited color choices while maintaining good strength and weather resistance.

Nylon offers the best flexibility and lightweight properties. Its smooth surface contributes to a quality glide, while its durability ensures long-lasting performance.

Forward-thinking manufacturers are also embracing recycled and biodegradable plastics, proving that sustainability and performance can go hand in hand.

Deconstructing the Zipper: Key Features and Benefits

A zipper is a tiny engineering marvel. Every time you zip up a jacket, precisely crafted components work together in harmony. This attention to detail separates a quality plastic zipper manufacturer from the rest. Understanding these components helps you make better choices for your products. For a deeper dive, check out our comprehensive guide. More info about zipper parts.

Zipper Teeth and Chain

The teeth (or elements) are the heart of any zipper. Their shape, size, and material determine the zipper’s strength and smoothness.

Standard teeth are versatile and reliable for most applications. Innovations include S-shaped teeth for improved strength, curved teeth for a unique look, and imitation metal teeth for a metallic appearance without the weight or corrosion concerns. Other specialized designs like reinforced teeth serve specific purposes, such as improved durability or aesthetics.

The zipper gauge or size—indicated by numbers like #3, #5, #8, #10—refers to the width of the teeth in millimeters when closed. A delicate #3 zipper is great for pockets, while a robust #10 can handle heavy-duty gear. Larger teeth generally mean greater strength but less flexibility.

Sliders, Pullers, and End Types

The slider is the mechanism that engages and disengages the teeth. Locking sliders have a mechanism that holds them in place, perfect for pants or bags where accidental opening is an issue. Non-locking sliders move freely and work well for decorative uses. Auto-lock sliders automatically lock when the puller is released.

The puller is a prime opportunity for customization. Custom puller designs can incorporate your logo, match brand colors, or feature unique shapes to set your products apart.

End types determine how the zipper integrates with your product. Closed-end zippers have a permanent bottom stop, ideal for pants and pockets. Separating zippers allow complete separation, essential for jackets. Two-way separating zippers have dual sliders and can open from either end, useful for long coats or sleeping bags. Finally, continuous chain is zipper material sold by the yard, allowing you to cut custom lengths for specialized applications.

Understanding MOQs and Lead Times

Understanding minimum order quantities (MOQs) and lead times is crucial for planning. The typical MOQ for most plastic zippers is around 5,000 pieces per color, though this can vary based on customization complexity. Always clarify MOQs directly with your supplier.

Production lead times for standard bulk orders can be as fast as 3-10 days. Custom orders with unique molds or special processes may take 10-15 days or longer. Sample orders are usually much quicker, often just 1-4 working days. If you need custom molds for sliders or pullers, factor in an extra 2-7 days for the initial setup.

How a leading plastic zipper manufacturer addresses sustainability

Forward-thinking plastic zipper manufacturers are taking sustainability seriously. The shift toward eco-friendly materials includes Recycled PET (rPET), which uses plastic from recycled bottles, and emerging biodegradable plastics.

Sustainable production processes are also key. This includes waste reduction through optimized production, robust chemical management (verified by certifications like Bluesign and Oeko-Tex), and investments in energy efficiency and water conservation.

Here’s how recycled and virgin plastic zippers stack up:

You don’t have to sacrifice quality for sustainability—recycled plastic zippers perform just as well as their virgin counterparts.

Choosing a US-based plastic zipper manufacturer

Partnering with a US-based manufacturer offers tangible advantages. On-time delivery becomes more predictable with shorter shipping distances and more reliable schedules. Supply chain reliability improves, protecting you from international disruptions and tariffs. Quality control oversight is easier with direct communication, eliminating language and time zone barriers. Choosing a domestic supplier also means supporting domestic industry and building a brand reputation that values American manufacturing excellence. We’re proud to be a US-based manufacturer with 80 years of experience. More info about our commitment to quality.

Sourcing Your Zippers: Customization and Logistics

Working with the right plastic zipper manufacturer means you can create a product that is uniquely yours. From color to puller design, customization brings your vision to life. While understanding logistics like MOQs and lead times can seem daunting, a good partner makes the process smooth.

Customization Options

Modern manufacturing offers an incredible range of customization options:

- Color matching: Manufacturers can match virtually any color for the zipper tape, plastic teeth, or both.

- Custom puller design: The puller is a tiny billboard for your brand. Create unique shapes, textures, or incorporate your logo directly into the design.

- Logo integration: Branding can be subtly woven into the zipper tape or even onto the teeth for a cohesive look.

- Size and length adjustments: Zippers can be produced in custom lengths beyond standard sizes like #3, #5, #8, and #10.

- Specialty finishes: A pearly lustre finish gives plastic teeth a shiny, sophisticated look. Reflective coatings can improve visibility, and anti-wrinkle tape helps maintain a professional appearance on delicate fabrics.

Ready to bring your unique zipper vision to life? Request a custom quote and let’s start creating something amazing together.

What Sets a Top-Tier Plastic Zipper Manufacturer Apart?

When searching for a plastic zipper manufacturer, you’re not just buying a product—you’re seeking a partner. The best manufacturers act as an extension of your team, bringing reliability, expertise, and quality to every project. At Lenzip, we’ve learned over eight decades that manufacturing excellence is about the relationships we build and the trust we earn. More info about our company.

Quality Assurance and Durability Testing

A top-tier manufacturer proves its quality through rigorous testing and recognized standards. Certifications like ISO 9001 show a commitment to consistent quality management systems. Oeko-Tex Standard 100 is crucial for products that touch skin, ensuring they are free from harmful substances. For sustainability, look for GRS (Global Recycled Standard) and Bluesign certifications.

Beyond certifications, leading manufacturers conduct demanding performance evaluations. These include strength tests (measuring lateral chain strength and puller durability), water resistance testing for outdoor gear, fire retardancy testing for industrial workwear, colorfastness testing, and wear resistance testing that simulates thousands of open-close cycles. Modern automated testing equipment ensures these evaluations are conducted efficiently and consistently.

The Role of Technology and Innovation

Technology has revolutionized the zipper industry. Automated production lines ensure consistency and efficiency. Smart manufacturers invest in R&D to develop custom molds and explore new materials and designs. Advanced molding techniques create intricate and durable teeth with incredible precision.

This innovation leads to zippers with improved durability, water resistance, fire retardancy, and anti-corrosion properties. Aesthetic innovations include pearly lustre teeth, multi-color combinations, and imitation metal finishes. Technology also supports sustainability in manufacturing by reducing waste and energy consumption.

Frequently Asked Questions about Plastic Zippers

We’ve heard just about every zipper question imaginable over our 80 years in the business. Here are answers to the most common questions people have when working with a plastic zipper manufacturer.

What is the typical minimum order quantity (MOQ) for custom plastic zippers?

The typical MOQ is around 5,000 pieces per color, but this isn’t set in stone. The final number can depend on the complexity of your order, such as a custom puller design or unique tooth shape. For standard items, there may be more flexibility. It’s always best to ask, as every project is different. For more details, check out our FAQ section. More info about ordering.

What is the main difference between a molded plastic zipper and a coil zipper?

The key difference is their construction and performance:

- Molded plastic zippers have individual teeth molded from durable plastic (like acetal resin) directly onto the tape. This makes them extremely strong and ideal for heavy-duty applications like jackets, luggage, and outdoor gear.

- Coil zippers use a continuous spiral of nylon or polyester sewn to the tape. This construction makes them more flexible and smoother to operate, perfect for apparel, bags, and items where the zipper needs to bend with the fabric. They can also be made as concealed zippers for an invisible finish.

What quality certifications should I look for in a manufacturer?

Certifications are a manufacturer’s report card, indicating their commitment to quality, safety, and responsibility. Key certifications to look for include:

- ISO 9001: This shows the manufacturer has a solid, consistent quality management system.

- OEKO-TEX® Standard 100: This is crucial for items that touch skin, guaranteeing that textile components are free from harmful chemicals.

- GRS (Global Recycled Standard) or Bluesign: These indicate a commitment to sustainability, from using recycled materials to environmentally responsible production.

Conclusion

We’ve explored plastic zippers, from the different types and materials to the intricate components that ensure they work flawlessly. It’s clear that creating a quality zipper involves precision engineering, rigorous testing, and a level of detail that separates good products from great ones. A top plastic zipper manufacturer doesn’t just make zippers; they create solutions that improve your products.

Your Partner in Production

We understand that every project is unique, which is why we offer the flexibility you need. Our B2B focus means we can support your business with options that work for you, including minimums as low as 25 units. We are not just a supplier; we are your partner, committed to helping you find the right solution to fit your specific requirements.

Let’s Find the Right Solution for You

Ready to upgrade to the Lenzip standard? We’re here to help.

Talk to a representative today. We’ll help you find the right solution for your project

Call us at (847) 368-9000 or request a quote today.