Your Go-To Guide:

Leading Metal and Plastic Zipper Manufacturers

Craft connections with leading metal zipper manufacturers. Dive into zipper anatomy, quality, and custom solutions for your needs.

Craft engineered connections with leading metal and plastic zipper manufacturers who understand the demands of modern textile engineering. This comprehensive guide explores zipper anatomy, materials, finishes, durability testing, polymer behavior, application-specific performance, customization options, and the industrial design considerations that determine long-term zipper reliability. Whether you manufacture marine enclosures, industrial equipment covers, apparel, tactical gear, or outdoor products, the right zipper isn’t just a hardware choice — it’s a structural decision that affects safety, service life, and user satisfaction.

The Essential Role of Zipper Engineering

A high-quality zipper is an engineered system built to withstand repeated mechanical stress, tensile load, humidity, corrosion, UV exposure, freeze–thaw cycles, abrasion, and chemical environments. Manufacturers who understand these demands, including U.S. engineering-driven suppliers like LenZip, create products far beyond simple commodity fasteners. Zipper performance depends on precise alignment of the chain, the geometry of the teeth, the weave and tensile stability of the tape, and the metallurgical or polymeric properties of the materials involved. To understand these foundational principles, review the fundamentals in Zipper Engineering 101.

The performance differences between zipper types have major consequences for OEMs and product teams. Metal zippers often deliver superior tensile strength, mechanical precision, and premium tactile feel, while molded plastic zippers excel in corrosion resistance, UV durability, cold-flex reliability, and outdoor weather performance. Nylon, polyester, polypropylene, brass, aluminum, Delrin, TPU coatings, and specialized plating systems all behave differently under stress, which is why selecting the right zipper style and material is a critical design responsibility. For a detailed understanding of materials, view Zipper Materials & Finishes.

This long-form guide combines decades of industry knowledge with engineering insight to help you specify the strongest, most durable, most reliable closures for your products — backed by the American manufacturing legacy of LenZip.

Understanding the Core: Anatomy of Metal and Plastic Zippers

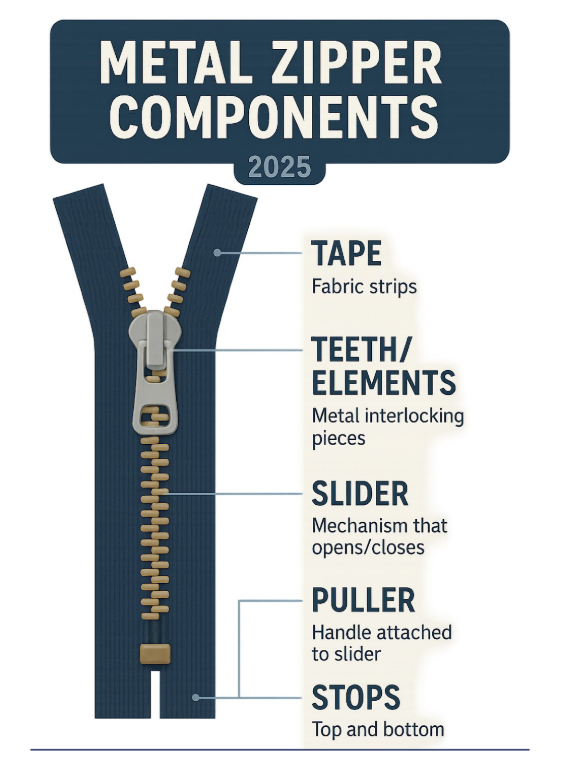

A zipper consists of five interdependent elements — tape, teeth, slider, puller, and stops. Each component affects zipper performance, longevity, smoothness, and resistance to environmental degradation. The tape forms the structural foundation, woven from polyester or cotton for tensile stability. The teeth, either molded polymer or precision-stamped metal, must maintain consistent geometry along the chain to prevent misalignment. The slider converts linear pulling motion into controlled interlocking force, while the puller provides ergonomic leverage for the user. Upper and lower stops ensure operational control and prevent the slider from running off the chain.

Every element must work in perfect mechanical harmony. Tape weave, monofilament quality, plating chemistry, lubrication treatments, and the pitch accuracy of the teeth all contribute to fatigue resistance and long-term performance. For a detailed technical breakdown of these components, see Guide to Zipper Teeth, Sliders, and Their Parts. Additional terminology can also be found in the Zipper Glossary.

The Advantages of Metal Zippers

Metal zippers remain the benchmark for heavy-duty performance, mechanical stability, tactile quality, and premium appearance across multiple industries. These zippers are typically manufactured from brass, aluminum, nickel, or stainless steel, each providing a unique balance of strength, corrosion behavior, surface hardness, and visual character. Brass offers exceptional fatigue resistance and corrosion tolerance with a warm, heritage-inspired aesthetic ideal for denim, leather, and lifestyle apparel. Aluminum provides lightweight strength suited for outerwear, luggage, and aviation textiles. Nickel delivers polished brightness and high surface smoothness, while stainless steel is the gold standard for marine, industrial, aerospace, and tactical environments that require extreme corrosion resistance.

Metal zippers are often chosen for apparel, luxury goods, industrial PPE, equipment covers, and tactical uniforms because they withstand abrasion, heat, stress, and repeated force. When appearance, durability, and tensile strength must converge, metal remains the preferred choice. For a closer comparison of metal substrates, see Brass vs. Aluminum Zippers. To understand why some metal finishes last longer than others, explore Zipper Coatings & Finishes.

Plastic Zippers: Modern Performance and Adaptability

Plastic molded-tooth zippers, often made from acetal or Delrin, represent the modern evolution of durable outdoor, marine, tactical, and industrial fastening systems. Instead of individual metal teeth clamped onto tape, molded plastic zipper teeth are injection-molded directly into the woven substrate, creating a strong, integrated bond that naturally resists rust, corrosion, fading, and chemical breakdown. Plastic zippers maintain flexibility in cold climates, resist UV degradation, tolerate chlorine and saltwater exposure, and perform consistently in freeze–thaw conditions. These attributes make them ideal for marine enclosures, boat covers, tents, outdoor cushions, protective industrial curtains, chemical containment systems, and technical apparel.

To learn how polymer behavior affects performance, explore Nylon vs. Polypropylene and Nylon vs. Polyester vs. Polypropylene. For a complete breakdown of cold-weather behavior, see Cold-Weather Zippers. For marine-specific conditions, review the guidance in Marine & Outdoor Zippers.

Comparing Metal, Coil, and Molded Plastic Zippers

Metal zippers deliver unmatched tensile performance and premium visual quality. Coil zippers provide light weight, flexibility, curve-friendly chain geometry, and quiet operation, making them ideal for luggage, pockets, and lightweight apparel. Molded plastic zippers represent the best balance of corrosion resistance, UV stability, marine-grade performance, and long-term durability for outdoor and industrial environments.

When evaluating which category to use, consider environmental exposure, load direction, abrasion levels, fabric structure, temperature extremes, and the required service life. For a comprehensive overview of zipper categories, visit Zipper Types Explained. For dimensional data, see the official Zipper Gauge Chain Size Chart. For direct comparisons, review Metal vs Plastic Zippers and Coil vs Molded Zippers.

A Guide to Zipper Finishes

A zipper’s finish affects corrosion resistance, UV stability, long-term color retention, lubricity, and friction coefficient. High-quality finishes protect metal teeth from oxidation, discoloration, abrasion, and environmental damage. Matte, polished, antique, and specialty finishes all behave differently under stress and exposure. A detailed overview can be found in Zipper Coatings & Finishes. For automotive applications where finish durability is essential, see Why Zipper Quality Matters in Automotive Interiors.

How Metal and Plastic Zippers Are Made

Zipper manufacturing blends precision metallurgy, polymer engineering, and controlled tape weaving. Metal teeth begin as wire, then undergo cutting, stamping, shaping, and crimping under strict tolerances. Polymer teeth are molded under heat and pressure to bond directly into tape fibers. Sliders are cast or machined, then assembled with pullers. The tape itself must maintain consistent width, tension, and weave density to prevent distortion under load. After assembly, zippers undergo finishing, lubrication, chain alignment checks, slider movement tests, and tensile validation. To explore these processes in detail, review How Zippers Are Tested for Strength, Corrosion & Fatigue and Inside Zipper Testing. For supply chain differences, see Continuous Chain vs Finished Zippers.

Testing & Certifications: Ensuring Reliability

Zippers used in industrial, marine, tactical, and outdoor environments must pass rigorous testing protocols. Leading manufacturers rely on:

ASTM D2061 tensile, chain strength, and slider fatigue testing

ISO durability and performance standards for long-term reliability

OEKO-TEX® Standard 100 for skin-safe materials

GRS (Global Recycled Standard) certification for recycled components

ISO 9001 quality management systems

For testing details, read Zipper Testing Standards.

Choosing the Right Manufacturer: What to Consider

Selecting a zipper manufacturer is a strategic engineering decision that affects product quality, reliability, and lead time. Technical support, documentation, plating durability, tape quality, mechanical tolerances, and consistency across production lots all matter. Domestic manufacturing from LenZip provides accountability, shorter turnaround, and reduced international supply chain risk. For an industry comparison, review LenZip vs YKK. To understand the value of U.S. production, see Why U.S. Zipper Manufacturing Matters.

Customization and Branding Opportunities

Custom zippers play a major role in brand identity. Pantone-matched tape colors, embossed pullers, engraved sliders, custom-plated finishes, proprietary molds, and RF-weldable tapes help designers and OEMs build unique, recognizable products. Options such as fire-resistant coatings, TPU laminations, and engineered specialty components allow deeper customization for industrial, marine, tactical, and aerospace markets. To explore these customization paths, visit Choosing the Right Zipper or explore custom assemblies at Custom Coverall Zippers.

Manufacturing Origin and Cost Considerations

Domestic suppliers offer consistent quality, reliable timeline adherence, ethical production, and direct communication. Offshore production can reduce unit cost but often introduces longer lead times, unpredictable plating quality, and lower testing standards. Many OEMs now prefer U.S.-based zipper manufacturing for traceability and engineering collaboration. Learn why North American sourcing is gaining momentum in U.S.-Made Zippers Are Gaining Ground.

Applications Across Industries

Different industries demand different zipper materials, coatings, gauges, and constructions. Common applications include:

Marine & Outdoor Fabrication: boat covers, biminis, enclosures, and UV-exposed outdoor gear. See Marine Fabricators.

Tents & Structures: load-bearing tension, cold-weather reliability, UV resistance. Explore Industry: Tents.

Upholstery & Cushions: furniture covers, cushions, modular seating. Reference The Best Cut-to-Length Upholstery Zippers.

Chemical & Industrial: hazmat suits, industrial curtains, containment barriers exposed to chemicals. See Zippers in Harsh Chemical Environments.

Technical Outdoor Gear: tents, packs, outerwear, and all-weather gear relying on molded-tooth durability.

Automotive, Aerospace & Defense: high-strength, flame-resistant, or airtight zippers used in high-stress environments.

For heavy industrial contexts, review Choose the Right Zipper for Industrial Applications.

Innovation and Sustainability in Zipper Design

Sustainability has become a defining factor in modern zipper manufacturing. Low-energy plating, solvent-reduced dyeing processes, recyclable polyester tapes, bio-based TPU coatings, and recycled polymer resins play a growing role in next-generation zipper design. Engineering teams evaluate tensile retention, hydrolysis resistance, colorfastness, UV stability, and weldability to ensure eco-conscious materials still deliver industrial-grade performance.

To explore recycled material options, see Recycled vs Virgin Polyester. To understand the broader sustainability program, review Eco-Engineered Zippers. For UV-related material issues, explore How UV Resistance Impacts Zipper Lifespan.

Partnering with LenZip: Precision That Lasts

LenZip delivers engineered reliability supported by domestic manufacturing, consistent plating quality, predictable production timelines, and deep customization capabilities. OEMs rely on LenZip for mission-critical applications that cannot afford zipper failure — whether in marine, industrial, tactical, apparel, upholstery, or aerospace environments.

Start your next project with engineering support and industry-leading quality. Submit your specifications through the official request portal:

Request a Quote

To explore all zipper options, view the full product catalog at:

LenZip Products

Frequently Asked Questions About Metal and Plastic Zippers

What is the strongest metal zipper?

Stainless steel offers the highest tensile strength and corrosion resistance. Troubleshooting support is available at Zipper Teeth Not Closing.How do I choose the right zipper size?

Refer to the official Zipper Gauge Chain Size Chart for accurate sizing.Are metal or plastic zippers better?

Metal excels in tensile performance and premium aesthetic; plastic excels in corrosion resistance and cold-weather reliability. Comparison available at Metal vs Plastic Zippers.Are eco-friendly zipper options available?

Yes — see Eco-Engineered Zippers.How do I repair a zipper?

Review the official repair guide: How to Fix a Stuck or Jammed Zipper.