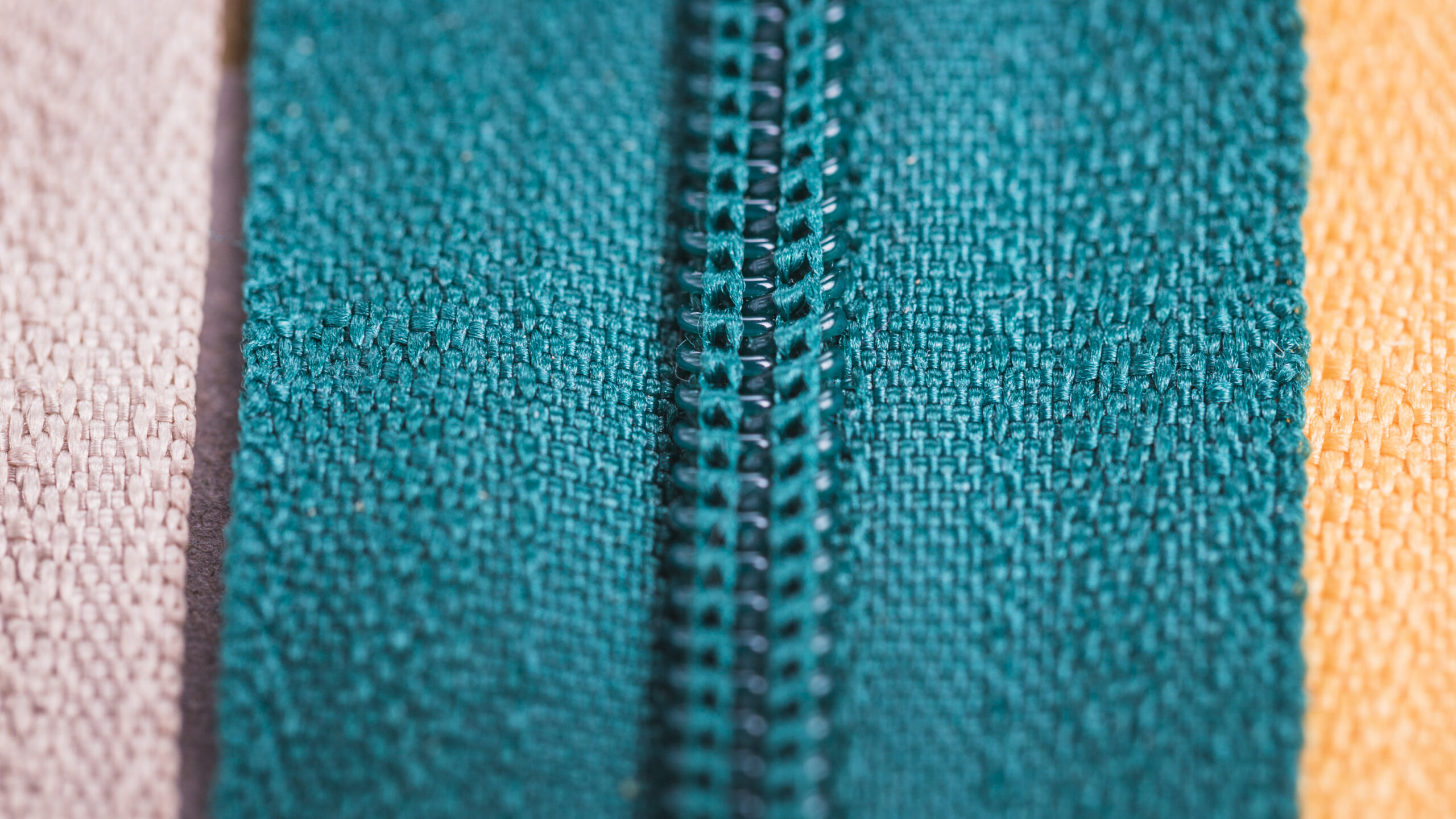

Every industrial product—whether it’s a safety harness, boat cover, or heavy-duty strap—depends on the reliability of its webbing. Yet behind that woven strength lies a critical material choice that affects not only performance but also environmental impact: recycled polyester vs. virgin polyester.

In a world where textile engineering meets sustainability, this distinction has never mattered more. Procurement teams and OEM engineers must evaluate not only tensile strength and UV resistance but also the fiber’s environmental footprint, cost stability, and long-term supply security.

At LenZip, these questions come up daily. As a U.S.-based zipper and webbing manufacturer serving industrial and commercial markets, LenZip helps OEMs understand how both recycled and virgin polyester contribute to strong, consistent, and sustainable webbing systems.

Understanding Virgin Polyester in Industrial Webbing

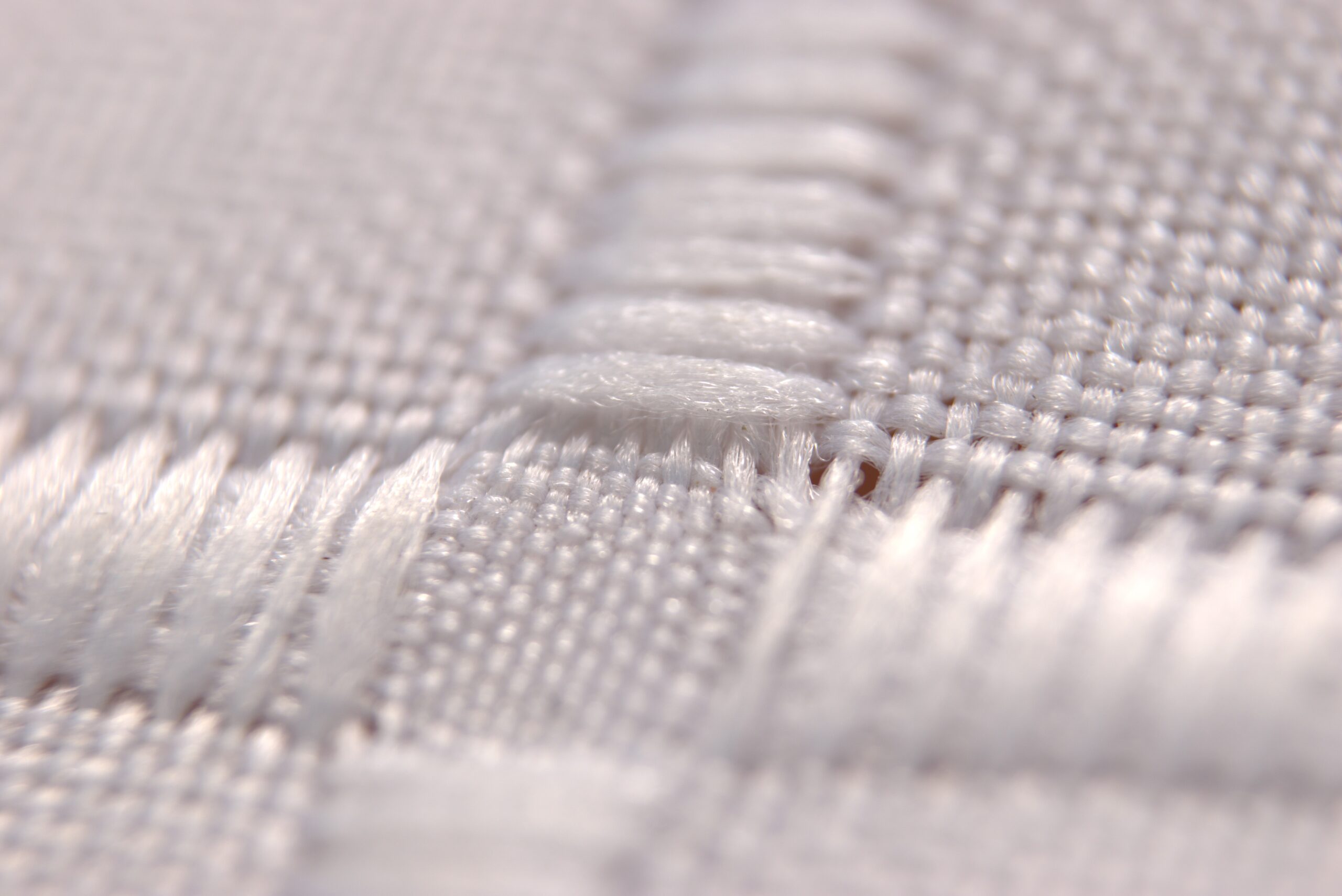

Virgin polyester is created from new petrochemical feedstocks using a continuous polymerization process that delivers precise control over molecular structure and fiber characteristics. These freshly synthesized filaments offer exceptional purity and uniformity—qualities that make them ideal for industrial-grade applications.

Virgin polyester webbing offers:

High tensile strength and low stretch, critical for load-bearing straps, structural enclosures, and high-stress assemblies.

Superior UV, heat, and chemical resistance, ensuring long-term stability in marine, automotive, and outdoor environments.

Consistency in dyeing and colorfastness, important for branded or visual products.

Excellent compatibility with industrial coatings like polyurethane or silicone used to create water-resistant webbing.

The polymer’s smooth surface ensures strong adhesion and predictable coating behavior, reducing quality variation from roll to roll.

For an in-depth comparison between fiber types, see Unraveling the Differences: Nylon and Polyester Explained and explore surface treatments on Zipper Materials & Finishes.

What Is Recycled Polyester (rPET) and How Is It Made?

Recycled polyester, often referred to as rPET, is produced from post-consumer PET bottles, manufacturing scraps, or other polyester waste. Through mechanical or chemical recycling, these plastics are transformed into resin pellets that can be extruded into new fibers.

The process typically involves:

Collection and cleaning: Sorting, washing, and shredding bottles into flake.

Resin reformation: Melting or depolymerizing flakes to rebuild the polyester chain.

Extrusion and spinning: Forming new filaments, texturizing, and weaving into webbing.

This transformation diverts plastic from landfills and oceans, helping close the loop in textile manufacturing. According to the Industrial Fabrics Association International (IFAI), modern rPET production can reduce carbon emissions by 40–60% and water use by up to 50% compared to virgin polyester.

LenZip compares recycled and virgin polyester webbing under identical test conditions—examining tensile behavior, UV degradation, coating adhesion, and elongation—so OEMs can confidently match sustainability targets without sacrificing performance.

Performance and Mechanical Comparison

Performance remains the cornerstone of webbing selection. Both recycled and virgin polyester can produce high-quality, heavy-duty webbing, but each excels in different areas depending on the application.

| Property | Virgin Polyester | Recycled Polyester (rPET) |

|---|---|---|

| Tensile Strength | Slightly higher; consistent batch-to-batch | Near parity in most industrial grades |

| Elongation | Uniform stretch characteristics | May vary slightly between batches |

| UV Stability | Superior under prolonged sunlight | Good; depends on stabilizer additives |

| Abrasion Resistance | Excellent wear performance | Slightly variable depending on filament source |

| Sustainability | Fossil-based, high energy input | Up to 60% less CO₂ emissions and energy use |

| Cost Efficiency | Stable, predictable | Can fluctuate with recycling supply availability |

Virgin polyester remains ideal for mission-critical applications—industrial lifting, safety harnesses, or long-term marine exposure—where maximum mechanical reliability is essential. However, rPET is quickly becoming the material of choice for most general-purpose industrial webbing where sustainable manufacturing and regulatory compliance are key.

Engineering and Environmental Considerations

Choosing between recycled and virgin polyester isn’t only about the yarn—it’s about how the entire assembly performs under tension, heat, and exposure.

LenZip evaluates tensile and fatigue strength under ASTM D6775 test protocols to ensure both recycled and virgin fibers meet expected performance levels.

Tensile and Fatigue Testing

Industrial webbing used in structural and safety products must meet defined break loads. Virgin polyester provides reliable tensile properties due to its molecular uniformity. rPET, while slightly more variable, performs equivalently when spun with advanced stabilization additives.

UV and Chemical Resistance

Marine and outdoor applications rely on polyester’s innate weatherability. Virgin polyester’s tighter polymer chains retain strength longer under constant sunlight and saltwater exposure, but recycled variants now achieve near-equal stability thanks to improved UV stabilizers and post-treatment coatings.

Coating Compatibility

Surface energy impacts coating adhesion—a critical factor for laminated or water-resistant webbing. Virgin polyester’s uniform surface delivers consistent adhesion, but with proper surface activation, rPET can achieve similar results.

For detailed webbing definitions such as denier, weave pattern, or elongation rate, explore Webbing Terminology.

Sustainability and the Industrial Supply Chain

The shift toward sustainable industrial textiles has redefined how OEMs evaluate suppliers. Webbing isn’t just a performance component—it’s a sustainability statement.

Governments, automotive manufacturers, and marine fabricators now integrate sustainability scoring into procurement. For many, recycled polyester webbing is a straightforward way to reduce carbon impact without redesigning entire product systems.

At LenZip, U.S.-based production adds another sustainability layer by reducing transoceanic freight emissions and ensuring full supply-chain traceability. Each webbing run—recycled or virgin—is documented with batch records, tensile data, and coating compatibility reports for compliance and certification.

According to Textile World, over 60% of global polyester fiber capacity is now recyclable or produced from partially recycled content. This marks a turning point for industries balancing environmental goals with material reliability.

By combining domestic manufacturing and responsible sourcing, LenZip supports both environmental responsibility and industrial performance.

Design and Application Guidance for OEMs

Whether selecting webbing for marine enclosures, tent systems, or modular structures, engineers must align material performance with use-case stress factors.

Virgin polyester remains the first choice for products that must endure decades of UV exposure, mechanical tension, and extreme temperatures. It’s common in military-grade and industrial safety applications where failure risk must be near zero.

Recycled polyester, however, is now a practical, cost-effective alternative for:

Light-to-medium duty enclosures

Upholstery and seat webbing

General industrial straps

Custom branded textiles seeking eco-certification

For integrative products—like zipper-webbing assemblies—LenZip’s engineers verify both zipper and webbing tensile compatibility to avoid seam failure. Learn more about that process in Zipper and Webbing Integration: Engineering Stronger Assemblies (internal reference example).

Why Choose LenZip for Industrial Webbing Solutions

LenZip is one of the few remaining U.S.-owned zipper and webbing manufacturers offering fully controlled domestic production. From fiber selection and weaving to coating, sewing, and tensile validation, every step happens in-house under ISO-compliant procedures.

This vertical integration allows LenZip to deliver both recycled and virgin polyester webbing with unmatched precision, short lead times, and verified test data.

LenZip partners directly with OEMs to:

Recommend materials optimized for tensile and UV requirements.

Provide full test documentation for ASTM and MIL-SPEC compliance.

Develop custom zipper-webbing assemblies that balance performance with sustainability.

Whether the focus is mechanical strength, long-term exposure resistance, or eco-friendly manufacturing, LenZip delivers engineered solutions backed by seven decades of American craftsmanship.

To begin a specification review or quote request, visit Request a Quote.

Conclusion

The comparison between recycled and virgin polyester webbing reflects a broader evolution in industrial materials—one where strength, sustainability, and supply transparency all intersect.

Modern recycled polyester has matured into a reliable, high-performing fiber capable of meeting the demands of most OEM and industrial applications. Meanwhile, virgin polyester remains indispensable for projects demanding the highest tensile reliability, exact color matching, and long-term UV stability.

By collaborating with LenZip, manufacturers gain more than a supplier—they gain an engineering partner dedicated to data-backed performance, domestic traceability, and forward-thinking sustainability.

Learn more about coatings, material finishes, and performance standards at Zipper Materials & Finishes.

Frequently Asked Questions

What’s the tensile difference between recycled and virgin polyester webbing?

Virgin polyester maintains a slight edge in tensile strength and stretch consistency. However, top-tier rPET webbing now meets ASTM D6775 tensile benchmarks for most industrial categories. LenZip tests each webbing line for mechanical compliance.

Is recycled polyester as durable for industrial use?

For the majority of medium-duty applications, yes. Modern rPET webbing offers excellent abrasion and UV resistance, with negligible differences in longevity compared to virgin fiber.

Can recycled polyester be used in marine environments?

Yes—with proper coatings and stabilizers, rPET performs reliably in marine and outdoor conditions. LenZip recommends matching coating chemistry to UV and moisture exposure.

How does LenZip validate webbing quality?

Through ASTM-compliant testing, including tensile, elongation, and coating adhesion trials. Results are archived and shared with OEM clients for traceable documentation.

Does LenZip produce sustainable or eco-certified webbing?

Yes. LenZip manufactures both virgin and recycled polyester options with full transparency, enabling brands to meet sustainability goals and compliance audits.

What applications benefit most from virgin polyester?

High-load, high-risk uses such as safety harnesses, industrial slings, and marine enclosures still rely on virgin polyester for absolute uniformity and strength retention.