From arctic expeditions to aerospace suits, temperature can determine how every zipper performs. A frozen slider or a softened chain can compromise even the best product design. For OEMs, engineers, and designers, understanding how temperature affects zipper flexibility, coating durability, and material integrity is vital for achieving reliable performance in any environment.

Since 1946, LenZip has engineered precision zippers in the United States that are built to endure the toughest conditions. Each product is tested across extreme temperature ranges—from sub-zero cold to industrial heat—ensuring smooth operation and long-term resilience. These temperature resistant zippers withstand environmental extremes that would cause other closures to seize or degrade.

For more insights into performance specifications, explore Inside Zipper Testing and Zipper Load Testing Explained.

How Temperature Changes Material Performance

Temperature influences every component of a zipper—metal, polymer, coating, and lubricant. Metals expand and contract, while plastics harden in cold or soften under heat. This can shift slider alignment, alter tooth interlock precision, or reduce bond strength between tape and fabric.

In cold weather, humidity can freeze within the zipper chain, locking it solid. Plastics that lose flexibility may crack or fail under minimal stress. Conversely, in high heat, polymers soften and deform, adhesives weaken, and UV exposure accelerates surface breakdown. Over time, these effects reduce zipper longevity and operational smoothness.

To counter these challenges, material experts at LenZip Manufacturing blend high-grade polymers and thermoplastic coatings formulated to sustain elasticity and dimensional stability across the broadest thermal spectrum possible. Learn more about our testing approach in How Zippers Are Tested for Strength, Corrosion, and Fatigue.

Selecting the Right Materials for Temperature Resistant Zippers

Each zipper material responds differently to temperature cycles, making material selection one of the most important design choices for performance and safety.

Nylon provides excellent flexibility in moderate cold but stiffens quickly below –20 °F and begins softening around 185 °F.

Polyester, valued for flexibility and UV resilience, performs consistently from freezing conditions up to 200 °F.

Polypropylene is lightweight and affordable but can become brittle below –4 °F.

Metal zippers—particularly brass and stainless steel—handle mechanical stress but heat up or chill rapidly to ambient temperatures.

The most versatile option remains TPU-coated zippers. Thermoplastic polyurethane retains flexibility from –40 °F to 200 °F while repelling moisture and resisting oxidation. This makes it suitable for outdoor, marine, and industrial use where equipment must remain reliable year-round.

For more details, explore Polypropylene vs Polyester and Nylon vs Polypropylene.

If you’re designing for heavy-duty industrial or marine environments, also see Airtight and Pressure-Resistant Zippers and Fire-Resistant Zippers: Engineering Safety.

Zipper Behavior in Cold Climates

Cold weather magnifies minor material flaws into significant performance issues. As temperature drops and humidity freezes, cheap plastics fracture upon flexing, and unprotected coatings chip or peel. Frost accumulation at the teeth or slider can also lead to operational lock-up.

LenZip combats these effects through innovative coatings and flexible polymer systems. Its cold-flex zippers use lubricated TPU coatings that repel moisture and maintain elasticity through temperatures as low as –40 °F. Cold-chamber tests reveal that polyester tape coil zippers outperform nylon equivalents at –25 °F, and brass-tooth zippers maintain functionality when ordinary materials fail.

Learn more in Cold-Weather Zippers: Preventing Freeze and Crack, where we demonstrate how flexible polymer chains sustain smooth movement under sub-zero stress.

For climate-specific engineering, see Zipper Coatings and Finishes.

How Heat and UV Exposure Affect Zipper Integrity

At the opposite temperature extreme, heat introduces softening, oxide buildup, and adhesion breakdown. Plastic teeth that soften after long exposure to 200 °F lose precise interlock, and UV rays further accelerate polymer fatigue. Over time, color fading, structural deformation, and oxidation lead to compromised strength.

LenZip counters these issues with heat-resistant pigments and UV-stable coatings proven through accelerated exposure testing. The results are presented in How UV Resistance Impacts Outdoor Zipper Lifespan and Zipper Coatings and Finishes. Designers requiring color retention and durability in outdoor applications rely on these specialty coatings to preserve both appearance and performance.

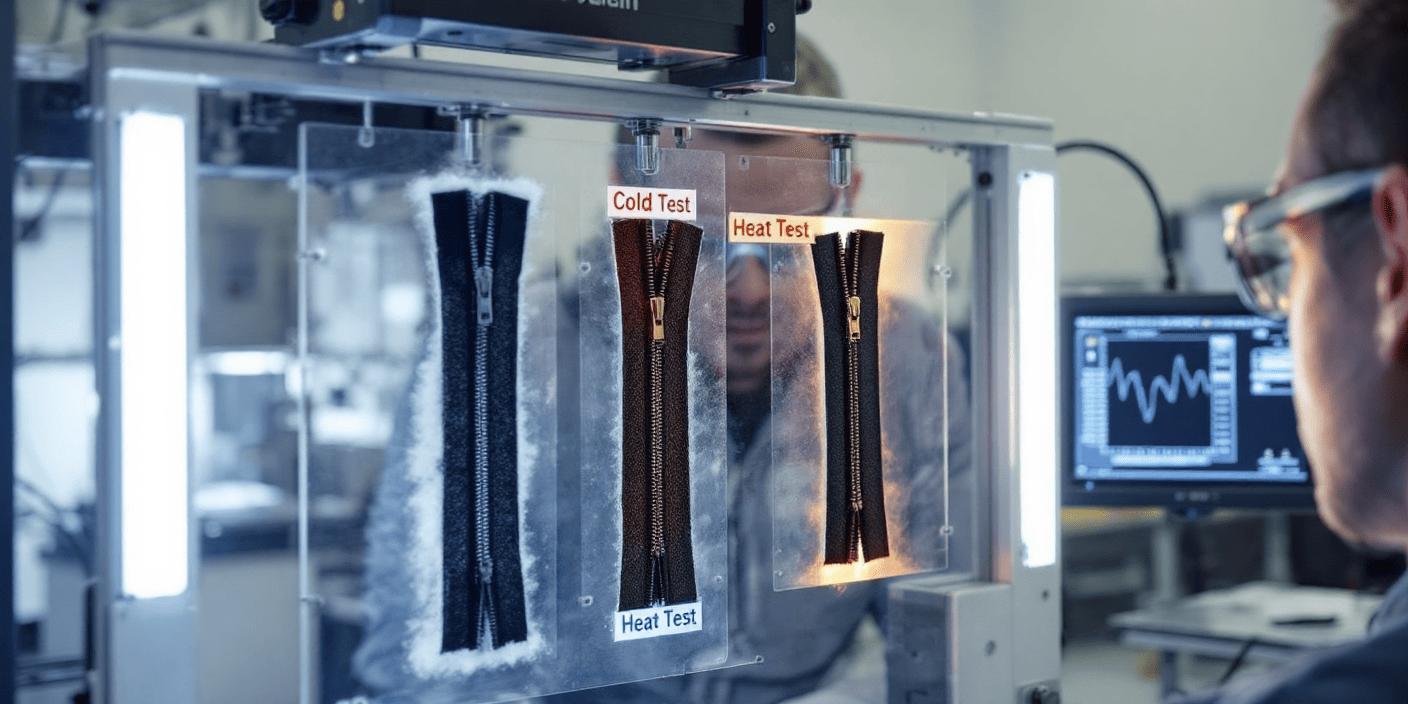

Testing and Performance Validation

Every LenZip thermal performance zipper undergoes comprehensive evaluation to confirm consistent motion, load-bearing strength, and dimensional accuracy across temperature extremes. Using ASTM D2061 and ISO 12947 protocols, zippers are subjected to thousands of alternating hot and cold cycles to simulate years of use.

This rigorous testing ensures that each product meets standard specifications for industrial and consumer reliability.

For deeper insight into laboratory testing and compliance validation, refer to Inside Zipper Testing and Zipper Load Testing Explained. LenZip provides detailed data reports to OEM partners for integration into quality assurance documentation.

Engineered Design for Longevity and Flexibility

Advances in material science have significantly increased the lifespan of temperature resistant zippers. LenZip integrates hybrid polymers, reinforced edge tapes, and lubricants that do not harden or degrade with temperature fluctuations. These designs keep sliders gliding freely under conditions ranging from –40 °F to 200 °F.

A standard configuration for all-climate outerwear includes polyester tape bonded with TPU coatings and nickel-plated sliders, balancing corrosion resistance with mechanical endurance. For sustainable alternatives, LenZip’s Eco-Engineered Zippers employ recycled materials and bio-based TPU while retaining equivalent heat and cold resistance.

Learn more about our sustainability philosophy in Eco-Engineered Manufacturing Practices.

Real-World Applications Across Industries

Thermally stable zippers play a critical role in multiple industries. In marine and outdoor manufacturing, they must withstand cycles of wetness, sun exposure, and freezing, maintaining closure reliability through extreme environmental stress.

In aerospace design, zippers face rapid pressure changes and thermal shock during operation. Industrial inflatables, containment curtains, and technical gear require coatings that resist chemical exposure and remain flexible at both freezing and scorching temperatures.

Similarly, protective clothing such as firefighter gear relies on flame-resistant closures with self-extinguishing finishes that maintain integrity even under short-term thermal spikes. These specialized applications highlight the need for rigorous testing, precise material matching, and in-house prototyping that LenZip provides through its vertically integrated engineering model.

For industrial applications requiring seam bonding, see RF-Welded & Heat-Sealed Zipper Integration.

Sustainability and Performance in Temperature Design

Modern zipper design increasingly merges performance with environmental stewardship. LenZip uses recycled polyester and plant-based TPU blends that retain flexibility and tensile strength in extreme environments. These choices reduce production footprint while maintaining ISO-compliant durability.

For brands focused on sustainability, temperature-proof zippers made from eco-conscious materials offer an effective balance of reliability and responsibility.

By combining endurance with sustainability principles, manufacturers can meet both functional and environmental goals—producing zippers that last longer, perform better, and minimize waste. Explore more at Eco-Engineered Zippers.

Best Practices for Specifying Temperature Resistant Zippers

Designing around temperature variability requires careful material coordination and laboratory verification. It’s essential to define operating temperature range, environmental exposure, and lifetime usage conditions early in development. This information allows engineers to recommend the appropriate polymer composition, coating, and test method.

When working with your supplier, focus on the following best practices:

Identify the target temperature range and expected exposure (e.g., –30 °F to 150 °F with intermittent UV).

Select tape and coating materials compatible with fabric type and environmental demands.

Request validation data from ASTM D2061 or ISO 12947 performance tests early in prototyping.

Proactive design collaboration ensures consistent quality control and reduces time lost in field adjustments or certification delays. For a technical consultation, connect via Request a Quote.

Why LenZip Leads in Thermal Zipper Engineering

LenZip’s fully domestic manufacturing model allows for direct collaboration between designers, technicians, and testing engineers. Each zipper design is reviewed and validated through in-house testing before release, ensuring reliable slider alignment, tape adhesion, and long-term functionality—even after over 10,000 thermal cycles.

This immediate feedback loop results in rapid prototyping, precise adjustments, and verified traceability. The company’s long-standing commitment to quality makes it a preferred partner for customers requiring dependable, industrial temperature zippers built for safety, endurance, and performance.

Learn more about LenZip’s 80-year history of innovation in About LenZip or begin consultation via Request a Quote.

Key Takeaways

Temperature dramatically affects zipper flexibility, coating adhesion, and mechanical stability.

TPU-coated and polyester-based zippers provide reliable performance across –40 °F to 200 °F.

ASTM and ISO thermal testing ensures proven strength and endurance across environmental cycles.

LenZip’s precision engineering guarantees dependable, sustainable performance in any climate.

FAQ: Temperature, Flexibility, and Zipper Performance

How does cold affect zipper flexibility?

Low temperatures cause standard plastics to stiffen and crack, while TPU-coated or polyester-tape zippers remain flexible down to –40 °F. Learn more in our Cold Weather Zippers Guide.

Which materials work best in heat?

Polyester, stainless steel, and TPU coatings retain structural stability beyond 180 °F, resisting distortion under continuous exposure. See Zipper Coatings and Finishes for thermal pigment data.

Do metal zippers handle temperature changes better than plastic?

Metal zippers resist fatigue and expansion distortion but can transfer temperature quickly, which may affect user comfort without insulation. Learn more in Metal vs Plastic Zippers.

How are zippers tested for temperature performance?

ASTM D2061 and ISO 12947 standards measure tensile strength, slider movement, and dimensional stability after hot–cold cycling. For details, visit Inside Zipper Testing.

Can temperature cause cracking or warping?

Yes. Lower-quality plastics fracture in cold or deform in heat. LenZip’s engineered materials prevent these failures through balanced elasticity and polymer stabilization.

What coatings resist freezing conditions?

Thermoplastic polyurethane and thermoplastic elastomers maintain elasticity and repel ice buildup, making them reliable even after extended sub-zero exposure.