Unzipping Strength:

The Ultimate Heavy-Duty Zipper Guide

Discover why heavy duty zippers are essential for demanding applications. Learn selection, materials, and care for ultimate strength.

Zippers may seem like small components, but in the world of industrial design and technical manufacturing, they play an outsized role in performance and reliability. When standard closures fail under stress, heavy-duty zippers step in as the unsung heroes of durability. These are the fasteners that protect vital gear, seal high-performance enclosures, and ensure equipment stays functional in the toughest environments.

At LenZip USA, we’ve spent more than 80 years perfecting this craft — blending American manufacturing precision with advanced polymer science and hands-on engineering expertise. Whether you build marine covers, tactical vests, industrial curtains, or outdoor protective gear, the right zipper is not just a finishing touch — it’s a mechanical guarantee that your product won’t quit when it’s needed most.

Why Heavy-Duty Zippers Matter

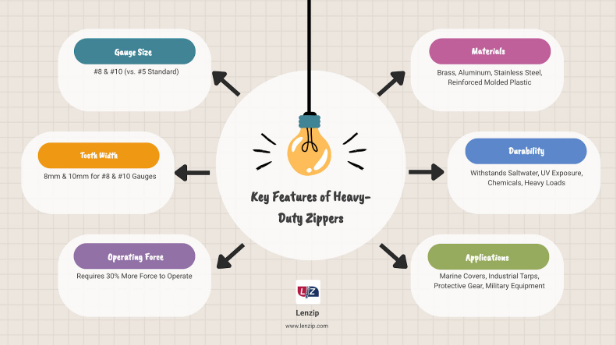

The difference between standard and heavy-duty zippers isn’t merely size — it’s the ability to withstand the extreme. A regular #5 zipper might suffice for light jackets or small bags, but when products are exposed to UV radiation, saltwater, heat, abrasion, or high mechanical load, failure isn’t an option. In these situations, #8 or #10 gauge zippers — with teeth measuring 8 to 10 millimeters across — become the go-to solution.

These larger zippers aren’t just tougher; they’re designed to handle 30 percent more operating force without distorting or separating. That added strength allows them to endure thousands of open-close cycles in conditions that would destroy standard hardware. The result is longer product lifespan, fewer failures in the field, and higher customer satisfaction. For businesses, it also means lower warranty claims and stronger brand trust — because nothing undermines quality like a jammed or broken closure.

Heavy-duty zippers are engineered to function like miniature machines. Every part — from the teeth and slider to the stops and tape — is designed to perform reliably under tension, flex, and environmental stress. It’s no coincidence that industries like marine fabrication, military manufacturing, industrial upholstery, and outdoor recreation rely on these components to hold their products together.

Understanding Gauge and Strength

At the heart of every zipper is its gauge, a numerical system representing the width of the zipper teeth when closed. The most common sizes range from #3 to #10, but for heavy-duty applications, the #8 and #10 gauges dominate. These larger sizes deliver more surface area for interlocking, resulting in significantly higher tensile strength.

A #5 zipper might measure just 5 millimeters across the chain, whereas a #10 gauge measures a full 10 millimeters. That may sound small, but in practical use, it can mean the difference between a zipper that gives way under strain and one that remains locked and stable for years.

Because of their increased rigidity and thicker tapes, heavy-duty zippers require greater operating force — often about 30 percent more than standard versions. But that stiffness isn’t a drawback; it’s proof of superior construction. This added resistance is exactly what makes them ideal for industrial tarps, marine enclosures, tents, and tactical gear that experience repetitive stress, bending, or heavy side-pulling forces.

For detailed specifications, the Zipper Gauge & Chain Size Chart on LenZip’s site provides a full breakdown of standard sizes, strengths, and recommended applications.

The Key Characteristics of Heavy-Duty Zippers

Several defining features separate a heavy-duty zipper from its lighter counterparts. The most visible is the size and thickness of its teeth — often molded or machined for maximum interlock. The chain must resist separation even when pulled from awkward angles or under high pressure.

Equally important is the strength of the tape, the woven fabric that holds the chain in place. Heavy-duty tapes are typically made from high-tenacity polyester or nylon, and in some cases, polypropylene. These fibers resist tearing, fraying, and ultraviolet degradation, ensuring the zipper performs in both humid and sun-exposed environments.

The slider is another critical component. In everyday zippers, sliders can deform after repeated use. Heavy-duty zippers, however, use precision-cast or forged metal sliders — often in brass, aluminum, or stainless steel — or high-impact molded polymers. Each is designed to withstand thousands of cycles without bending, corroding, or locking up.

Even the smallest parts, such as the top and bottom stops, are reinforced. These prevent the slider from detaching during operation — a failure that could otherwise render an entire garment or piece of equipment unusable. Combined, these components create a closure system that balances strength, reliability, and long-term ease of use.

You can explore each part of a zipper in depth with LenZip’s Guide to Zipper Teeth, Sliders, and Their Parts.

Materials That Define Durability

Just like fabrics, zipper materials determine how well they’ll perform in a specific environment. Heavy-duty zippers are made from three main material families — molded plastic, metal, and nylon coil — each with distinct strengths and weaknesses.

Molded plastic zippers are the backbone of outdoor and marine products. The plastic teeth are molded directly onto the tape, forming a watertight bond. This design offers natural corrosion resistance and UV stability, allowing molded zippers to remain flexible even after years of sun and salt exposure. They’re commonly used in boat covers, tents, marine enclosures, and cold-weather apparel.

Metal zippers are the definition of rugged. Available in brass, aluminum, or stainless steel, they deliver superior strength and longevity. Brass offers excellent corrosion resistance and an appealing aesthetic, aluminum balances lightness with durability, and stainless steel provides unmatched resistance to rust and chemicals — essential for industrial safety gear and chemical containment fabrics. Learn more in LenZip’s Metal vs Plastic Zippers.

Nylon coil zippers, though flexible, are surprisingly tough. Formed by continuous nylon filament, they excel in applications that require bending or curvature, such as sleeping bags, tents, and flexible industrial covers. Their ability to realign minor misalignments when the slider passes over makes them incredibly reliable. For a deeper comparison, visit Coil vs Molded Zippers.

If you’re choosing between base materials, LenZip’s guides to Polypropylene vs Polyester and Nylon vs Polyester vs Polypropylene break down the chemistry behind performance.

Different Types of Heavy-Duty Zippers and Their Uses

Choosing the right zipper type is as critical as selecting the correct material. Each configuration offers unique advantages based on how and where the product will be used.

Separating zippers completely detach at the bottom, allowing two panels to come apart — ideal for jackets, covers, or modular structures that need full access.

Closed-end zippers remain joined at one end and are common in bags, cushions, and fixed covers where partial access is sufficient.

Two-way zippers feature dual sliders, enabling access from either end. They’re particularly valuable in long garments, sleeping bags, and industrial enclosures where ventilation or mid-access is needed.

Water-resistant zippers include vinyl or polyurethane coatings to prevent water ingress — often removing the need for storm flaps.

Finally, fire-resistant zippers use specialized materials to maintain integrity at high temperatures. These are essential for firefighting gear, foundry suits, and high-heat industrial apparel, and LenZip’s FR zipper line is engineered to meet the highest safety standards.

For an in-depth comparison of every style and application, see Zipper Types Explained.

LenZip vs. YKK and Other Brands

YKK may be the most recognized name globally, but LenZip’s U.S.-manufactured zippers rival or surpass their performance in many applications — and often with greater flexibility and faster delivery.

LenZip’s zippers are fully customizable, available in hundreds of colors, lengths, and slider designs. They’re produced domestically, giving OEMs confidence in supply chain stability, shorter lead times, and direct technical collaboration.

Unlike imported fasteners, LenZip zippers are tested in-house to ASTM and ISO standards, ensuring consistent results for strength, corrosion, and fatigue. Learn more about this comparison in LenZip vs YKK.

How to Select the Right Heavy-Duty Zipper

Selecting a zipper is a precise process. It’s not simply about choosing the thickest chain — it’s about aligning the zipper’s capabilities with the environmental and operational demands of your project.

Start by assessing the application environment. A zipper performing flawlessly indoors might corrode in a marine or chemical setting. For outdoor and coastal use, corrosion-resistant coatings and molded teeth are non-negotiable.

Next, evaluate frequency of use and load direction. Products that will be opened hundreds of times per day, such as equipment covers or industrial curtains, require sliders designed for high-cycle operation. Similarly, large covers or tarps that endure lateral tension demand wider gauges and reinforced tape.

Finally, consider fabric compatibility. Even the strongest zipper can underperform if paired with weak or overstressed fabric. Proper alignment between zipper and textile strength ensures both components share the load evenly.

LenZip frequently manufactures custom-length and extra-long zippers for specialized applications, including industrial curtains, tents, and containment barriers. Our engineers can tailor gauge, slider type, and finish to meet your exact specifications — no project is too complex.

Caring for Heavy-Duty Zippers

Even the toughest zippers require maintenance to stay in peak condition. Debris, sand, and salt are common culprits that lead to premature wear and jamming.

Routine cleaning is simple but effective. A damp cloth or soft brush can remove surface debris from between the teeth. For marine or outdoor gear, rinsing with fresh water after saltwater exposure is vital. Salt crystals can corrode metal or stiffen plastic if left unchecked.

After cleaning, apply a silicone-based lubricant — never oil — to reduce friction and protect against moisture. These lubricants create a clean barrier without attracting dirt, unlike petroleum-based alternatives that trap grime.

Regular inspection also goes a long way. Look for bent teeth, worn sliders, or frayed tape, and replace small parts promptly. When a tooth is missing or the tape is torn, replacement becomes necessary. To explore proper repair techniques, check out How to Fix a Zipper.

For detailed maintenance guidance, see Zipper Maintenance & Care and Zipper Care Tips.

Your Partner in Production

At LenZip, we don’t just manufacture zippers — we help build products that last. As one of the few remaining U.S. zipper manufacturers, we’re proud to deliver consistent quality, small-batch flexibility, and complete customization for OEMs and fabricators. Whether you need 25 zippers or 25,000, we align our production with your specifications and delivery timelines.

We believe engineering support should come standard. Our technical team collaborates directly with designers and production managers to ensure every zipper is tested, rated, and optimized for the environment it will face. This hands-on approach allows our customers to achieve greater consistency, faster prototyping, and fewer field failures.

Explore our Products, learn About LenZip, and Request a Quote to begin your next build with a trusted partner in precision fastening.

Frequently Asked Questions About Heavy-Duty Zippers

Can a heavy-duty zipper be repaired, or does it always need replacement?

In many cases, a heavy-duty zipper can be repaired — but it depends on what’s damaged. If the slider is worn, bent, or no longer aligns properly, a replacement slider usually restores full function. Similarly, if top or bottom stops fall off, they can often be reattached or replaced without removing the entire chain.

However, if the teeth are missing, the tape is torn, or the zipper has been warped from overexposure to heat or chemicals, the only reliable fix is a complete replacement. Heavy-duty zippers are designed for strength, not for tooth-by-tooth repair, since their chain components are fused or machined into one integral structure.

For guidance on diagnosing damage and DIY vs. professional solutions, read How to Fix a Zipper.

What are the most common uses for heavy-duty zippers?

You’ll find heavy-duty zippers in environments where normal zippers would fail. They’re standard in marine upholstery, industrial tarps, tactical packs, firefighter suits, tent doors, and protective covers. These zippers often serve as structural components — not just closures — in products that experience high stress or require environmental sealing.

In the marine industry, heavy-duty zippers resist UV degradation, corrosion, and salt exposure. For military and tactical gear, they provide durability under constant abrasion and heavy load-bearing situations. In industrial settings, they protect machinery and materials from dust, debris, and chemicals.

To see how LenZip serves multiple sectors, explore Industry Solutions.

How do I choose the correct zipper size for my project?

Zipper size corresponds to the width of the closed chain, measured in millimeters. A #5 zipper measures about 5 mm across the teeth, while #8 and #10 measure 8 mm and 10 mm respectively.

For light apparel or bags, a #3 or #5 zipper is sufficient. For marine, outdoor, or industrial projects, move up to #8 or #10. These larger zippers provide more interlocking surface area and stronger tensile resistance.

LenZip’s Zipper Gauge & Chain Size Chart provides a simple reference for selecting the correct gauge based on your application’s fabric weight and load requirements.

Are metal or plastic zippers better for industrial use?

Both have strengths depending on the application. Metal zippers — particularly brass and stainless steel — offer unmatched tensile strength and longevity. They’re ideal for industrial and fire-resistant gear where exposure to heat and abrasion is common.

Molded plastic zippers, on the other hand, are excellent for marine and outdoor use. They resist corrosion, UV degradation, and water intrusion. For lightweight flexibility and ease of curvature, nylon coil zippers are preferred, particularly for soft goods and flexible panels.

LenZip provides all three materials and explains the differences in Metal vs Plastic Zippers and Coil vs Molded Zippers.

What makes a zipper “quality”?

A quality zipper performs smoothly under load, resists corrosion, and maintains alignment even after thousands of uses. Key indicators include uniform teeth alignment, high-quality tape stitching, and properly sized sliders with smooth travel.

Premium zippers, like those made by LenZip, also undergo extensive testing for strength, corrosion, fatigue, and environmental exposure, following ASTM and ISO testing standards. In practical terms, a quality zipper doesn’t just close — it operates consistently and quietly without catching or separating.

How should I maintain heavy-duty zippers for long-term performance?

Maintenance is simple but vital. Keep zippers clean and lubricated to prevent debris buildup, which can wear down teeth and sliders over time. For outdoor and marine gear, rinse with fresh water after salt exposure and let dry before storage.

Apply silicone-based lubricants (never oil) periodically to maintain smooth operation and prevent corrosion. Check the chain for bent teeth or worn sliders and replace components at the first signs of damage to prevent total failure.

For detailed step-by-step instructions, see Zipper Maintenance & Care.

Are YKK zippers really better than others?

YKK is a well-known global brand, but “better” depends on your needs. LenZip’s U.S.-manufactured zippers match or exceed YKK’s performance standards — with the added advantages of faster lead times, smaller minimums, and direct collaboration with American engineers.

LenZip also offers fully custom zippers — down to color, pull design, and finish — ensuring you get a zipper built exactly for your product’s performance requirements. Learn more in LenZip vs YKK.

Can I order custom-length or specialty zippers from LenZip?

Absolutely. LenZip specializes in cut-to-length and extra-long zippers, serving projects that require exact dimensions or unique configurations. We regularly produce zippers extending several feet for industrial curtains, containment systems, and tent structures.

Our engineers can tailor gauge, slider material, finish, and even chain type to suit your specific requirements. To get started, visit Custom-Fit Demystifying Cut-to-Length Zippers or Request a Quote.

How much does a luggage or gear zipper repair cost?

If you’re handling the repair yourself, replacement sliders or repair kits are typically under $20. Professional repairs can range from $75 to $125, depending on the complexity, zipper length, and product type. For premium luggage or technical gear, this is still far more cost-effective than replacing the entire product.

You can learn more about these repair types at Luggage Zippers.

What causes a zipper to separate or split open after closing?

Separation occurs when the slider becomes loose or worn, preventing the teeth from aligning properly. Over time, pressure and use can widen the slider channel, reducing its grip. Other causes include bent teeth, worn tapes, or debris buildup in the chain.

To fix the issue, the slider often needs to be replaced or gently crimped back into shape using pliers. For a full walkthrough, read Zipper Teeth Not Closing.

Are LenZip zippers tested for harsh conditions?

Yes. Every LenZip heavy-duty zipper undergoes mechanical, corrosion, and environmental testing in accordance with ASTM and ISO standards. We replicate conditions such as salt spray, freeze-thaw cycles, and UV exposure to ensure real-world reliability.

These tests validate the zippers’ ability to perform under the extreme temperatures, moisture, and load cycles encountered in marine, industrial, and tactical environments. Our goal is simple: to ensure the zipper outlasts the product it’s built into.

Does LenZip offer environmentally friendly zipper options?

Yes — LenZip has developed eco-engineered zippers using recycled materials and low-impact coatings. These products reduce manufacturing waste and carbon footprint while maintaining the strength and reliability of traditional fasteners.

We also offer recyclable nylon and polyester tapes compatible with sustainable garment programs. Learn more in Eco-Engineered Zippers.

How do I know which zipper type is right for my application?

Choosing the right zipper depends on factors like environment, fabric type, and desired function. For marine or outdoor gear, use corrosion-resistant molded plastic zippers. For protective apparel, choose fire-retardant metal zippers. For industrial covers or bags, nylon coil zippers provide flexibility and durability.

If you’re unsure, LenZip’s engineers can help you match materials, sliders, and coatings for optimal performance. Start by reviewing Choosing the Right Zipper or contact our team for technical guidance.

Does LenZip produce zippers in the United States?

Yes. LenZip proudly manufactures its zippers in the United States — a distinction that ensures faster production, tighter quality control, and greater supply chain stability. Our domestic manufacturing approach allows us to work directly with OEMs on custom builds, small runs, and technical prototyping, supporting industries that depend on fast, consistent sourcing.

Read more about our commitment to U.S. production in Why U.S. Zipper Manufacturing Matters.

What’s the lifespan of a heavy-duty zipper?

When properly maintained, a LenZip heavy-duty zipper can last as long as — or longer than — the product it’s installed in. Metal zippers in controlled environments can last decades, while molded plastic versions in marine or outdoor use typically last several years of constant exposure before showing wear. Regular cleaning, lubrication, and storage out of direct sunlight significantly extend service life.

Where can I learn more about zipper engineering and performance testing?

LenZip offers extensive educational content, covering every aspect of zipper construction and testing. For deeper insight, explore:

These resources break down how zippers are tested for load, corrosion, and fatigue to ensure each component meets its intended performance standards.