Find unbreakable performance! Explore heavy duty sliders: definitions, types, applications, & maintenance for ultimate durability.

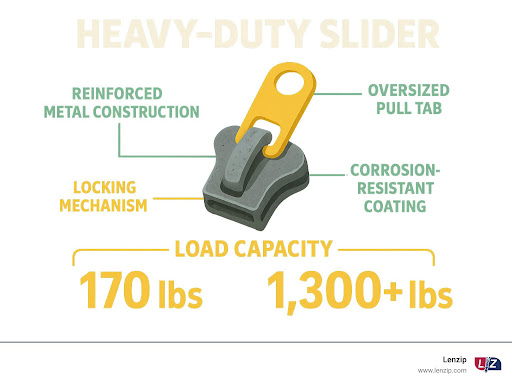

Heavy duty sliders are the backbone of zippers that need to withstand extreme conditions and repeated use. These specialized zipper components handle loads of 170 pounds or greater and require approximately 30% more force to operate compared to standard sliders.

Quick Answer for Heavy Duty Slider Buyers:

- Load Capacity: Handle 170+ lbs up to 1,300+ lbs depending on application

- Materials: Zinc-plated steel, stainless steel, or reinforced metal construction

- Key Features: Locking mechanisms, corrosion resistance, self-repairing capabilities

- Top Applications: Industrial workwear, military gear, marine equipment, aerospace components

- Critical Specs: Gauge matching, pull strength ratings, temperature resistance

Whether you’re manufacturing firefighter suits, astronaut gear, or heavy-duty luggage, the slider is what makes or breaks your zipper’s performance. A failed slider means a failed product – and potentially dangerous situations for end users.

The difference between standard and heavy-duty sliders isn’t just about strength. These components feature larger teeth sizes, stiffer tape construction, and specialized coatings that resist salt water corrosion, UV damage, and extreme temperatures.

This guide breaks down exactly what makes a slider “heavy-duty” and where to source the most reliable options for your manufacturing needs.

What Defines a “Heavy-Duty” Zipper Slider?

Think of the difference between a regular house key and a bank vault key. Both open locks, but one is built for everyday use while the other needs to handle serious security demands. That’s exactly the gap between standard and heavy duty sliders.

Robust materials are what separate the champions from the wannabes. Heavy duty sliders rely on powerhouse materials like zinc-plated steel, stainless steel, and hard anodized aluminum. These aren’t random choices – each material brings serious resistance to corrosion, wear, and the kind of punishment that would make a standard slider wave the white flag.

When you’re choosing between metal sliders and plastic sliders, think about your application. Plastic works fine for lightweight jobs, but when things get tough, metal takes the crown. Metal sliders deliver superior tensile strength and can handle the constant friction of thousands of open-close cycles without breaking a sweat.

The superior construction goes way beyond just picking tough materials. Heavy duty sliders feature beefier profiles with thicker walls, reinforced stress points, and pull tabs that won’t snap off when you need them most. These design choices spread stress evenly across the slider body, preventing those frustrating failures that always happen at the worst possible moment.

Here’s where heavy duty sliders really shine in their performance characteristics:

Strength comes first – these sliders handle significant pull forces and side loads that would destroy regular zippers. They require about 30% more force to operate, which isn’t a bug, it’s a feature. That extra resistance means they’re gripping those zipper teeth with serious authority.

Durability means they’re built for the long haul. Whether facing harsh chemicals, extreme temperatures, or constant exposure to dirt and debris, these sliders keep performing. Some industrial applications test sliders for 10,000 cycles, and quality zipper sliders aim for that same reliability.

Friction resistance ensures smooth operation even under heavy loads. Nobody wants a zipper that fights them every step of the way. Quality heavy duty sliders glide efficiently along the zipper chain through precision manufacturing and specialized coatings when needed.

Temperature resistance keeps everything working whether it’s arctic cold or desert hot. The materials maintain their structural integrity across extreme temperature ranges without becoming brittle or losing their grip.

Understanding these fundamentals helps you appreciate why heavy duty sliders are so critical for demanding applications. They’re the reliable workhorses that keep your products functioning when failure isn’t an option.

For more detailed information about zipper components and terminology, check out our comprehensive guide: More info about zipper components.

A Guide to Different Types of Heavy Duty Sliders

Think of choosing a heavy duty slider like picking the right tool for a job. You wouldn’t use a butter knife to cut through rope, and you shouldn’t use just any slider for demanding applications. After 80 years in the zipper business, we’ve learned that matching the right slider to the right job makes all the difference.

When we design heavy duty sliders, we consider three main factors: how they function, what they’re made from, and where they’ll be used. Each of these elements plays a crucial role in determining which slider will serve you best.

Functional classification is all about how the slider behaves on the zipper chain. Two-way sliders are perfect for applications like sleeping bags, tents, and luggage where you need access from both ends. These sliders can move independently or meet in the middle, giving you incredible flexibility.

Separating zippers require sliders that can completely disconnect one side of the zipper from the other – think jacket fronts or tent doors. The slider needs to smoothly guide the teeth apart and back together without binding or catching.

Material differences dramatically impact performance and cost. Steel sliders offer incredible strength at a reasonable price point. We typically zinc-plate them for corrosion resistance, making them ideal for industrial workwear and heavy-duty bags.

Stainless steel sliders are our go-to recommendation for marine applications and outdoor gear. They laugh off saltwater, humidity, and harsh weather conditions. Yes, they cost more upfront, but they’ll outlast standard sliders by years in challenging environments.

Aluminum sliders shine when weight matters. Hard anodized for durability, they provide excellent strength without the bulk. Aerospace applications and high-end outdoor gear often specify aluminum for this reason.

Application-specific designs mean we tailor each slider to its intended use. A slider for a firefighter’s protective suit faces different challenges than one for a museum storage container. We consider the specific stresses, environmental exposures, and user needs for each application.

Key Features of Heavy duty sliders

The devil is in the details when it comes to heavy duty sliders. These key features separate good sliders from great ones.

Locking mechanisms prevent accidental opening when it matters most. Imagine a critical equipment bag popping open at the worst possible moment – not something you want to experience! Our locking sliders use internal spring-loaded components that engage with the zipper teeth. You need deliberate action to open up them, providing security and peace of mind.

Non-locking sliders serve a different purpose entirely. When you need quick, frequent access – like utility pouches or tool bags – a smooth-operating non-locking slider is your friend. No fumbling with locks when time is critical.

Slider size must match the zipper’s gauge perfectly. Larger, more substantial sliders handle the bigger teeth of heavy-duty zippers. This isn’t just about fit – it’s about distributing stress evenly and preventing deformation under heavy loads.

Gauge matching is absolutely non-negotiable. A mismatched slider will bind, slip, or fail prematurely. After eight decades of manufacturing, we’ve learned this lesson well – precision in matching saves headaches later.

Tab styles might seem like a small detail, but they make a huge difference in real-world use. Our heavy duty sliders feature robust, often oversized tabs that work even with gloved hands. Whether you’re on a construction site or climbing a mountain, you need a tab you can actually grip and use.

Pull strength ratings tell you how much force the slider can handle before breaking or detaching. Our heavy duty sliders are engineered to withstand significant pulling forces. That’s why they require more operating force – it signals a stronger, more secure connection.

Specialized Heavy duty sliders for Extreme Conditions

Some environments don’t just demand strength – they require sliders that can handle specific extreme conditions while maintaining smooth operation.

Water-resistant sliders keep performing even when soaked. While the slider alone doesn’t make a zipper waterproof (that’s the job of the tape and coatings), the right slider design minimizes water intrusion and prevents binding when wet.

Marine-grade sliders represent the pinnacle of corrosion resistance. Crafted from high-grade stainless steel, these sliders shrug off saltwater, constant humidity, and UV exposure. Boat covers, marine enclosures, and coastal equipment rely on these specialized sliders to keep functioning season after season.

Corrosion resistance extends beyond just marine applications. Industrial environments with chemicals, high humidity, or temperature extremes all benefit from sliders that won’t rust, pit, or degrade over time.

UV protection matters more than most people realize. Prolonged sun exposure can weaken plastic components and even affect certain metals. Our specialized sliders maintain their strength, color, and smooth operation despite years of UV bombardment.

Self-repairing features work hand-in-hand with the zipper teeth to create systems that can realign themselves after minor separations. While the zipper teeth do most of the work, a precisely engineered slider helps guide everything back into proper alignment, extending the overall life of the zipper system.

Top Applications for Heavy-Duty Zippers

When you think about where heavy duty sliders make their mark, you might picture construction sites or military bases. But the truth is, these tough little workhorses show up in some pretty surprising places! From protecting astronauts in space to keeping your camping gear dry on a rainy weekend, our heavy duty sliders are quietly doing their job everywhere reliability matters.

Let’s start with industrial apparel, where failure simply isn’t an option. Picture a firefighter rushing into a burning building – their gear needs to work perfectly every single time. The same goes for factory workers, utility crews, and yes, even astronauts suiting up for a spacewalk. These folks put their gear through incredible stress, and their heavy duty sliders need to handle constant opening and closing while enduring heat, chemicals, and rough handling. When someone’s safety depends on a zipper staying closed (or opening quickly when needed), that’s where our sliders truly shine.

The world of military gear and tactical equipment presents its own unique challenges. Combat uniforms, protective vests, and specialized equipment cases face conditions that would destroy ordinary zippers in no time. Whether it’s desert sand, arctic cold, or the chaos of field operations, heavy duty sliders keep performing when lives depend on it. That quick access to a medical pouch or the secure closure of a communication device? That’s our slider technology at work.

For outdoor enthusiasts, heavy duty sliders are the unsung heroes of trip. Your tent zipper working smoothly during a sudden storm, your backpack staying securely closed during a challenging hike, or your sleeping bag sealing out the cold – these moments define the difference between a great outdoor experience and a miserable one. We’ve seen too many camping trips ruined by failed zippers, which is why we engineer our sliders to handle whatever nature throws their way.

Travel presents its own set of challenges, making luggage and bags another prime application for our technology. Think about what your suitcase endures – overpacking, rough baggage handlers, and countless trips through airport security. Those two-way zippers on your duffel bag work overtime, and our heavy duty sliders ensure your belongings stay protected no matter how many miles you travel.

The marine world is particularly demanding, which makes marine applications perfect for showcasing our expertise. Boat covers face relentless sun, salt spray, and constant wind. Yacht interiors need zippers that look great while resisting humidity and corrosion. Our stainless steel sliders don’t just survive these conditions – they thrive in them, maintaining smooth operation season after season.

But here’s where it gets really interesting – heavy duty sliders show up in places you’d never expect. Fire trucks and RVs rely on them for secure storage compartments. Museums use them in specialized storage systems for priceless artifacts. Even some banking equipment depends on our slider technology for secure access to internal components.

The beauty of heavy duty sliders lies in their versatility. Whether we’re talking about a construction worker’s tool pouch, a paramedic’s equipment bag, or a research station’s weatherproof enclosure, the same principles apply: reliability, durability, and performance when it matters most.

At Lenzip, we’ve spent 80 years perfecting these applications because we understand that behind every heavy duty slider is someone who depends on it working perfectly. That’s not just our job – it’s our responsibility.

Frequently Asked Questions about Heavy-Duty Zipper Sliders

We love hearing from customers about heavy duty sliders – and honestly, we get asked the same great questions over and over again. That tells us you’re thinking smart about these critical components! Getting the details right can make or break your product’s performance, so let’s dive into the most common questions we field every day. For even more answers to questions you might have, check out our comprehensive FAQ section: More info about common questions

How do I choose the right size heavy-duty slider?

Think of choosing the right slider size like finding the perfect pair of shoes – it needs to fit just right, or you’re going to have problems. The golden rule here is all about zipper gauge, which is basically the size of your zipper’s teeth measured in millimeters when the chain is closed.

Here’s where it gets interesting: a No. 10 heavy-duty zipper has teeth that measure about 10mm wide when closed. That slider needs to be engineered specifically for those 10mm teeth – no exceptions.

Matching your slider to the teeth isn’t just important, it’s absolutely critical. We’ve seen what happens when people try to force a slider that’s too small onto heavy-duty teeth – it binds up, breaks, or just refuses to budge. On the flip side, a slider that’s too big will slide around loosely, never giving you that secure closure you need.

The chain width grows along with the gauge, which means bigger zippers need bigger, stronger sliders. That’s actually a good thing for heavy-duty applications because that extra size translates directly into more strength and durability.

Don’t forget to think about your specific application needs too. The gauge match is non-negotiable, but the style and material can vary based on how you’ll use it. If your workers will be operating that zipper with thick gloves on a fire truck, you’ll want a chunky pull tab that’s easy to grab. For a boat cover that’ll face years of salt spray, stainless steel becomes your best friend.

Can a broken heavy-duty slider be replaced?

This is probably our most popular question, and the short answer is usually yes – but there’s a catch you need to know about.

Replacing a broken heavy duty slider is definitely doable with the right approach. The replacement process involves carefully removing the old slider and sliding a new one into place. You’ll typically need to work with the top or bottom stop of the zipper chain to get the old slider off.

For the necessary tools, keep it simple: good pliers, wire cutters, and maybe a specialized zipper repair kit if you’re doing this regularly. It’s not rocket science, but it does require a gentle touch – especially with heavy-duty components that don’t forgive rough handling.

Here’s the important part though: if the teeth on your zipper are damaged, bent, or missing, replacing just the slider won’t fix your problem. We always tell customers that individual teeth on a heavy-duty zipper can’t be replaced if they’re broken – the whole zipper needs to go.

So when should you replace the whole zipper? Any time you see damaged teeth, torn tape, or if your slider is built into a specialized system that can’t be separated. While sliders can often be swapped out, we recommend taking a hard look at the overall condition first. For mission-critical applications, sometimes starting fresh with a complete zipper replacement is the smart move.

What is the best way to maintain a heavy-duty zipper?

Taking care of your heavy duty sliders is like maintaining any other high-performance equipment – a little attention goes a long way toward keeping them working smoothly for years.

Cleaning debris is your first line of defense. Dirt, sand, lint, and other crud love to build up in slider mechanisms and between zipper teeth. This creates friction and makes everything harder to operate. A simple wipe-down with a damp cloth works wonders for regular maintenance. For stubborn grime, try a mild soap solution, but make sure to rinse thoroughly and let everything dry completely.

Lubrication can work miracles on metal heavy duty sliders. A tiny amount of zipper-specific lubricant (usually wax-based or silicone-based) applied to the teeth can transform a sticky zipper into one that glides like butter. Just remember – less is more here. Apply it sparingly, run the slider back and forth a few times to spread it around, and avoid petroleum-based products that can attract dirt or damage the zipper tape.

Proper usage might be the most important maintenance tip we can share. Never force a stuck slider – instead, gently work it back and forth until it frees up. Always make sure fabric or other material is clear of the teeth before zipping. Pull the slider straight, not at an angle, and with two-way zippers, make sure both sliders are properly engaged before closing.

Good storage habits can extend your zipper’s life significantly. Keep zippers in clean, dry places when not in use. Avoid cramming items into tight spaces where the zipper might get stressed or bent. When possible, store items with zippers fully closed – this keeps the teeth properly aligned and ready for action.

Follow these simple steps, and your heavy duty sliders will keep performing like champions for years to come.

Conclusion: Choose Quality for Unbreakable Performance

When you really think about it, heavy duty sliders are pretty amazing little workhorses. We’ve taken quite a journey together exploring these seemingly simple components, and what we’ve finded is that there’s nothing simple about them at all. They’re precision-engineered marvels that quietly hold our world together – from the gear that keeps our first responders safe to the luggage that protects our vacation memories.

Throughout this guide, we’ve seen how the right materials make all the difference. Whether it’s zinc-plated steel for industrial strength, stainless steel for marine environments, or aluminum when weight matters, every choice is deliberate. The superior construction with reinforced stress points, larger profiles, and specialized coatings isn’t just engineering showing off – it’s the foundation of reliability when everything is on the line.

Think about all those applications we covered. The firefighter whose life depends on their gear staying secure. The soldier whose tactical equipment must never fail. The family whose tent zipper keeps them dry during a storm. In every case, the heavy duty slider is the unsung hero making it all possible.

Here’s what really strikes us: the importance of quality in these components goes far beyond convenience. When a standard zipper fails, you might get a little frustrated. When a heavy-duty zipper fails, people can get hurt. Equipment can be lost. Missions can fail. That’s why reliability and safety aren’t just nice features – they’re absolute requirements.

At Lenzip, we’ve spent 80 years perfecting our craft because we understand this responsibility. We don’t just manufacture zippers here in Rolling Meadows, Illinois – we create custom commercial and industrial zippers that become part of critical systems. Our commitment to unparalleled quality, integrity, and reliable on-time delivery isn’t marketing speak. It’s our promise that when you choose our products, you’re choosing components that won’t let you down when it matters most.

The next time you’re designing a product that needs to perform under pressure, the slider might be small, but its impact is enormous. Choose quality. Choose reliability. Choose heavy duty sliders that are built to last.

Ready to experience the Lenzip difference? Explore our custom zipper products and find what 80 years of American manufacturing excellence can do for your next project.