Why Coating Chemistry Defines Performance

In modern zipper engineering, the chemistry of the coating determines far more than surface appearance—it defines flexibility, sealing integrity, environmental resistance, and overall longevity. Every zipper used in outdoor gear, industrial curtains, or marine fabrication is only as good as its tape coating. Between thermoplastic polyurethane (TPU) and polyurethane (PU), the difference is substantial. TPU delivers exceptional strength and weldability under stress, while PU remains valued for its soft, matte finish and cost efficiency.

LenZip USA, one of America’s most trusted zipper manufacturers, engineers both TPU- and PU-coated zipper tapes for high-performance applications that require reliable sealing, temperature endurance, and long-term flexibility. Their in-house extrusion and coating lines are designed to meet ASTM and ISO standards, ensuring every tape is tested for durability, hydrolysis resistance, and adhesion strength. For more on zipper coatings and finishes, explore Zipper Materials & Finishes.

What Are TPU and PU Coatings?

From a polymer science perspective, TPU (Thermoplastic Polyurethane) belongs to the thermoplastic elastomer family, composed of alternating hard and soft molecular segments. This structure allows TPU to soften with heat, harden upon cooling, and be repeatedly reshaped without losing structural integrity. Because of this, TPU can be RF-welded or heat-sealed, forming seamless bonds with compatible textiles—a critical property for airtight or water-resistant zipper applications.

PU (Polyurethane) coatings, in contrast, are typically thermoset polymers. Once cured, their chemical crosslinks lock into a permanent structure that cannot be re-melted or reprocessed. PU coatings offer a uniquely smooth, soft hand-feel and an elegant appearance, which is why they remain common in apparel, upholstery, and decorative accessories. However, their lack of weldability and reduced flexibility under repeated stress limits their use in heavy-duty or sealed applications.

For additional context on textile and polymer performance, visit Polypropylene vs. Polyester and Unraveling the Differences: Nylon and Polyester Explained.

TPU vs. PU: Key Physical & Chemical Differences

When evaluating coated zipper tapes, engineers analyze properties such as elongation, weldability, heat resistance, and hydrolytic stability. TPU consistently outperforms PU in mechanical strength and flexibility, while maintaining superior adhesion and chemical resistance.

| Property | TPU (Thermoplastic Polyurethane) | PU (Polyurethane – Thermoset) |

|---|---|---|

| Flexibility | Excellent (>500% elongation) | Moderate (100–300%) |

| Heat Resistance | Up to 200 °F (93 °C) | About 160 °F (71 °C) |

| Weldability | RF & heat sealable | Limited (stitch-only) |

| Hydrolysis Resistance | High | Moderate |

| Mechanical Strength | High (Tensile: 40–55 MPa) | Moderate (20–35 MPa) |

| Adhesion/Peel Strength | Strong fabric bond | Moderate; degrades when wet |

| Abrasion Resistance | Excellent | Good |

| UV Resistance | High | Moderate—tends to yellow |

| Cyclic Flex Performance | Exceptional; >1 M cycles | Weakens after ~100 K cycles |

| Environmental Impact | Recyclable thermoplastic | Limited recyclability |

| Service Lifespan | Long-term | Shorter (1–2 years typical) |

For deeper data on test parameters, see Zipper Testing Standards and Inside Zipper Testing.

Environmental Stress and Real-World Performance

TPU-coated zipper tapes are built to withstand demanding conditions that destroy conventional coatings. They remain flexible and elastic even at –40 °F, resist cracking through repeated freeze–thaw cycles, and retain sealing capability after years of exposure to sunlight and moisture. TPU’s superior chemical resistance prevents degradation from fuels, oils, and industrial cleaning agents, making it ideal for use in marine enclosures, inflatable shelters, containment suits, and cleanroom barriers. Its UV stability ensures minimal yellowing and no surface chalking even under prolonged outdoor use.

PU coatings, while softer to the touch, are more vulnerable to long-term environmental wear. Under extended sunlight or frequent cleaning, PU tends to harden, yellow, and eventually develop surface cracks. While its texture is excellent for fashion zippers, upholstery, or luggage, it is less suited for industrial or marine applications where heat, chemical exposure, and moisture are constant. For a broader look at how different coatings age, explore Zippers in Harsh Chemical Environments and Temperature Resistant Zippers.

Industrial Applications and Material Selection

Across industries, the coating choice dictates long-term performance. TPU-coated zipper tapes are preferred for marine, medical, outdoor, and industrial environments where weldability and endurance matter most. They are used in inflatable shelters, industrial curtains, containment barriers, and cleanroom partitions, where seams must remain airtight and flexible through constant stress. TPU’s ability to fuse directly with PVC, TPU, or PU-coated fabrics allows for seamless integration through RF welding, eliminating needle holes and potential leak paths.

PU-coated tapes, by contrast, serve best in soft goods that emphasize touch and appearance over mechanical performance. They are frequently chosen for decorative apparel, fashion jackets, and upholstery projects, offering a smooth surface with modest water resistance. Although PU cannot be RF-welded, it provides an attractive finish that aligns with consumer-oriented products. More about these use cases can be found under Industry Applications and Zippers for Protective Covers, Curtains & Enclosures.

Testing TPU and PU Coatings for Strength and Flex

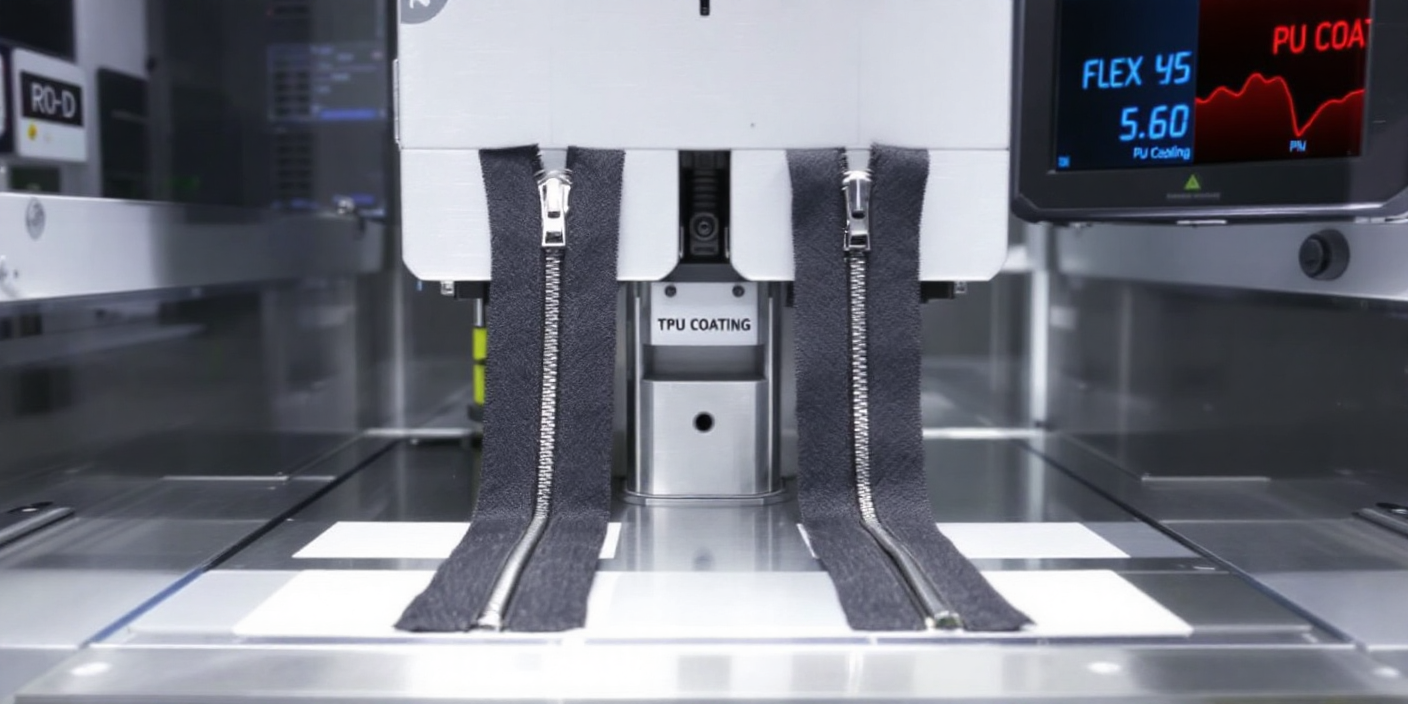

At LenZip’s in-house laboratories, coated zipper tapes undergo a series of mechanical and environmental tests to validate performance under load and stress. ASTM D412 tensile testing measures breaking strength, while ISO 527 assesses elongation at break. Adhesion and peel tests evaluate how well the coating bonds to the underlying tape, ensuring that the coating remains intact through cycles of flexing and exposure to water or chemicals.

Accelerated UV, hydrolysis, and fatigue tests simulate years of service in a controlled timeframe. TPU consistently demonstrates resilience, enduring more than one million flex cycles without failure, while PU tends to exhibit surface cracking and stiffness after roughly 100,000 cycles. For more insight into testing methodology and case studies, visit How Zippers Are Tested for Strength, Corrosion, and Fatigue.

LenZip’s Engineering Approach to Coated Zipper Tapes

Engineering excellence at LenZip USA begins with process precision. Each coated zipper tape is produced with controlled layer deposition, maintaining consistent TPU or PU thickness between 50 and 150 microns. This ensures flexibility without compromising sealing power. Substrate materials, including nylon coil and molded plastic chains, are carefully matched with the appropriate coating to maximize adhesion and bending endurance.

All testing is conducted in LenZip’s U.S.-based facilities, ensuring that each product meets ASTM and ISO standards for tensile strength, abrasion resistance, and hydrolysis stability. LenZip’s R&D team also develops custom TPU blends for medical and marine use, providing RF-weldable and non-leaching films compatible with sterilization and cleanroom protocols. The same engineering rigor extends to temperature-resistant and chemical-resistant zippers, designed to survive extremes of heat, cold, and pressure.

For an overview of zipper anatomy and part function, see Guide to Zipper Teeth, Sliders, and Their Parts.

Sustainability and Lifecycle Considerations

Sustainability has become a decisive factor in material selection, and TPU offers clear advantages. As a thermoplastic, TPU can be reheated and recycled, reducing waste and environmental impact. Some bio-based TPU grades now incorporate renewable carbon content while maintaining the same durability. PU, being a thermoset, cannot be remelted and is generally non-recyclable.

LenZip’s Eco-Engineered Zippers program promotes recyclable TPU materials and energy-efficient production lines, aligning performance engineering with environmental responsibility.

Design and Aesthetic Flexibility

Both TPU and PU coatings allow creative freedom in color, surface texture, and branding. TPU provides a high-gloss, transparent finish that pairs well with technical fabrics, while PU offers a matte, leather-like look ideal for apparel or decorative goods. LenZip can color-match zipper tapes to customer fabrics, apply branding elements, or integrate custom logos directly into coated surfaces. This fusion of aesthetic and engineering precision reflects the company’s expertise in balancing performance with design appeal. For related guidance, see How to Match Zipper Color and Tape to Fabric.

Beyond “Waterproof”: Advanced Uses for Weldable Zippers

Today’s market demands zippers that deliver more than water resistance—they must maintain airtight performance, chemical resilience, and thermal stability. TPU-coated zippers are the standard for RF-welded and heat-sealed systems, used in inflatable shelters, medical tents, and containment suits where seals must hold pressure and block contaminants. Their ability to retain flexibility between –40 °F and 200 °F allows them to perform reliably in both cold-weather zippers and industrial enclosures.

LenZip’s innovation in TPU-coated systems also supports marine fabricators, aerospace textiles, and industrial curtains requiring long-term strength under environmental exposure. To explore examples of these weldable systems, visit RF-Weldable Zippers for Inflatable Shelters & Medical Tents.

Conclusion: Selecting the Right Coating for the Job

Choosing between TPU and PU coatings requires balancing performance demands, aesthetic goals, and cost considerations. TPU is the clear choice when applications call for flexibility, durability, weldability, or chemical and UV resistance—making it ideal for industrial, marine, and technical apparel sectors. PU remains relevant for projects emphasizing softness, cost efficiency, or decorative appeal in fashion and upholstery markets.

LenZip’s engineering team works directly with OEMs and designers to match coating type to application, ensuring every zipper performs under expected load and environment. To request detailed specifications or begin a custom project, visit LenZip’s Request a Quote page or explore their Products lineup for coated, custom, and specialty zippers.

Frequently Asked Questions

Are TPU zipper coatings recyclable?

Yes. TPU is a recyclable thermoplastic that can be reprocessed and re-molded, making it a sustainable choice for industrial manufacturing.

Can PU-coated zippers be RF-welded?

No. PU is a thermoset polymer that cannot be re-melted or fused through RF welding. TPU, however, can be seamlessly bonded to compatible fabrics during heat sealing.

What temperature range can TPU-coated zippers handle?

TPU zippers remain flexible and strong from –40 °F to 200 °F, ideal for both cold storage and high-heat industrial environments.

Which coating lasts longer outdoors?

TPU coatings outperform PU in UV resistance, hydrolysis stability, and flex life, making them the superior option for marine, outdoor, and industrial use.

Does LenZip customize coating formulations?

Yes. LenZip engineers tailor TPU and PU coatings to meet application-specific needs, from medical-grade sterility to saltwater durability.