Why Webbing Terminology Matters

In industrial and commercial textile manufacturing, understanding webbing terminology is essential for ensuring precision, safety, and reliability. From aerospace and defense systems to outdoor equipment and automotive assemblies, webbing straps and webbing fabric form the load-bearing backbone of modern design. Yet the language surrounding webbing—terms like tensile strength, denier, warp, or weft—can be confusing without a proper reference.

Just as zipper terminology defines how closure systems function, webbing terms establish how materials perform under stress. The right understanding leads to better decisions, improved specifications, and safer end products. For related insight into closure component vocabulary, see Zipper Terms You Should Know.

At LenZip, terminology isn’t just technical—it’s the foundation of engineering communication. As a U.S.-based webbing and zipper manufacturer, LenZip helps OEMs translate material data into practical, tested results through integrated webbing, zipper web spider, and 2-way zipper assemblies. To explore compatible products, visit LenZip’s Products.

Webbing Basics: Warp, Weft, and Weave Structure

To understand industrial webbing, it’s important to grasp its core structure. Every webbing strap begins with two thread systems: warp threads, which run lengthwise on the loom, and weft threads, which interlace across the width. The combination of these two directions determines both strength and flexibility.

Different weave patterns create distinct performance characteristics. A plain weave follows a simple over-under structure for balanced durability. Twill weave produces a diagonal rib that improves flexibility and abrasion resistance. Satin weave creates a smoother surface, preferred for comfort or aesthetic applications.

These structural decisions affect how webbing handles stress, elongation, and friction—just as zipper chain gauges influence how zippers engage. Designers who understand the relationship between weave type and material behavior can better specify components for their applications. For cross-reference of dimensional sizing systems, view LenZip’s Zipper Gauge & Chain Size Chart.

Common Webbing Terms: The Essential Glossary for Engineers

Understanding webbing glossary terms allows designers and engineers to specify materials accurately, prevent production errors, and maintain quality control.

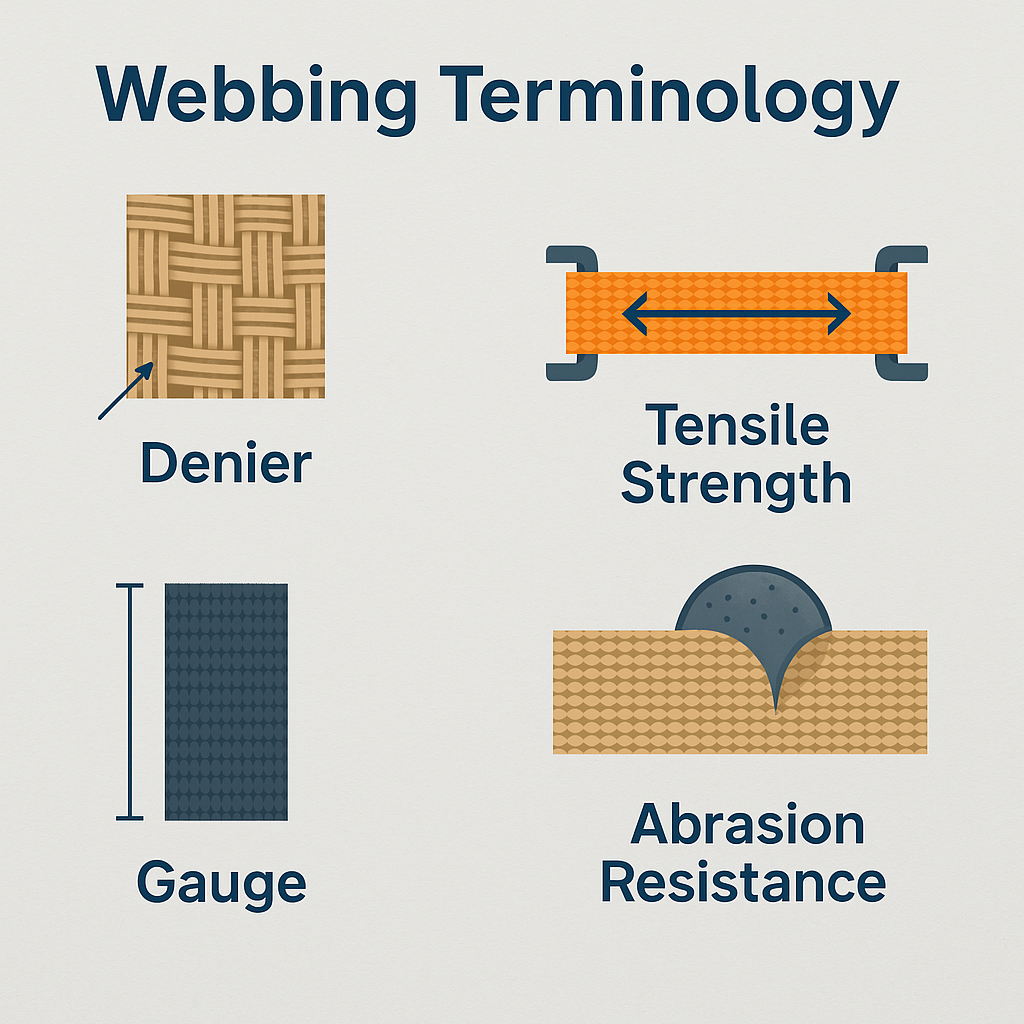

- Denier: Measures fiber thickness—the weight in grams per 9,000 meters of thread. A higher denier indicates thicker, heavier yarns with greater strength.

- Tensile Strength: The maximum load a webbing strap can handle before failure, often measured in pounds-force or newtons according to ASTM D6775 standards.

- Coating: A surface treatment (like polyurethane or PVC) applied after weaving to enhance resistance to UV, flame, or chemical exposure.

- Abrasion Resistance: The ability of webbing fabric to withstand repeated friction or bending cycles.

- Gauge: The thickness or density of a webbing strap, comparable to zipper gauge systems.

- Breaking Point: The stress level at which webbing fibers rupture.

- UV Stability: Resistance to degradation caused by sunlight—critical for outdoor and marine applications.

- Mil-Spec: Military specification; defines standardized quality, strength, and testing criteria for defense-grade materials.

Each of these attributes forms the basis of technical evaluation during quality testing and product certification. Zipper products undergo similar assessments—see Zipper Testing Standards for comparison.

Specialized Terminology: Application-Based Webbing Definitions

Beyond general vocabulary, certain industries use specialized terminology to define webbing built for unique environmental or safety conditions.

Marine-Grade Webbing:

Designed for resistance to saltwater, sunlight, and mildew. Typically woven from polyester webbing or polypropylene webbing, marine-grade options maintain structure and color even after long-term UV exposure. They often incorporate surface coatings detailed in Zipper Materials & Finishes.

Flame-Retardant Webbing:

Created to withstand high heat and flame, commonly found in PPE, firefighter gear, and industrial uniforms. It may use aramid fibers (like Kevlar® or Nomex®) or be chemically treated with fire-resistant coatings.

Anti-Static Webbing:

Includes conductive yarns that safely dissipate static electricity, protecting sensitive electronics and preventing charge accumulation in aerospace environments.

Through close collaboration, LenZip helps OEMs customize heavy-duty webbing for these and other specialized purposes—matching fiber choice, coatings, and finishing methods to precise performance goals.

How to Read Webbing Specifications

Webbing specification sheets can appear overwhelming at first glance, but learning how to interpret them is key to safe product design. Each document outlines construction details that predict field performance.

- Fiber Material: Indicates base polymer—nylon, polyester, or polypropylene—each with unique stretch, water-resistance, and chemical properties.

- Weave Type: Describes pattern (flat, tubular, herringbone) and how it distributes load or flexibility.

- Tensile Rating: Defines maximum load capacity, expressed in lbf or N.

- Finish or Coating: Lists treatments like UV inhibitors, flame retardants, or waterproof layers that enhance lifespan.

When assessing these attributes, designers should match fiber properties and weave strength with intended use—marine straps, PPE harnesses, or industrial tie-downs. LenZip’s engineers can review specs and recommend compatible zipper-webbing assemblies; start with a consultation at LenZip’s Request a Quote.

Why Webbing Standards Matter

Every safety-critical industry—from firefighting to aviation—relies on verified webbing standards. Proper terminology ensures materials are tested, rated, and traceable.

The ASTM D6775 standard specifies how to determine the breaking strength and elongation of textile webbing using calibrated test grips. Results establish the tensile performance profile, confirming that webbing meets its rated capacity. These tests mirror those used for zipper tapes and closure systems during Zipper Testing Standards.

Other international benchmarks include ISO 13934, NFPA 1971, and MIL-W-4088, which outline performance levels for elongation, chemical resistance, and environmental exposure. For reference, explore ASTM International to see how industry standards are developed and maintained.

By adhering to these frameworks, LenZip ensures every U.S.-made webbing product delivers verified strength, consistent weave integrity, and full material traceability. Domestic manufacturing not only supports sustainability but also enables faster lead times and dependable quality assurance. Visit the About Us page to learn how LenZip maintains its American manufacturing legacy.

FAQs

- What does “denier” mean in webbing?

Denier measures fiber thickness by weight—the grams per 9,000 meters of thread. Higher denier webbing straps are thicker, stronger, and more abrasion-resistant. - How do I measure webbing strength?

Webbing strength is determined by tensile testing, which applies force until failure. Official methods are defined in ASTM D6775, providing accurate load ratings for industrial webbing. - What’s the difference between warp and weft?

Warp threads run the length of the webbing; weft threads run across its width. Their intersection defines the weave structure, influencing flexibility and load capacity. - Are there industry standards for webbing testing?

Yes. Standards such as ASTM, ISO, and MIL-SPEC ensure that industrial webbing meets strict performance and safety criteria before approval. - How can LenZip help with custom webbing specs?

LenZip works directly with OEMs to engineer custom polyester webbing and integrated zipper-webbing systems tailored to tensile, environmental, and design requirements.

Learn more in Webbing Terminology, or explore related materials in Zipper Materials & Finishes.