Zippers might appear simple, but behind every smooth glide and secure closure lies decades of engineering refinement. From tooth geometry and slider pressure to tape construction and material science, each element is meticulously designed to balance flexibility and strength. At LenZip, zipper performance is the outcome of controlled precision and continuous innovation. Every zipper must operate flawlessly under stress, cycle after cycle, without deformation or corrosion.

Understanding the mechanical principles behind zipper design can help OEMs, manufacturers, and designers choose the right configuration for their product—whether it’s a marine enclosure, automotive interior, or industrial cover.

The Science Behind Zipper Strength

Zipper strength comes down to how effectively each component carries load across the system. When a zipper is engaged, the slider compresses each element, forcing the teeth or coils into interlock. The material must withstand both tensile stress (pulling apart) and compressive stress (teeth biting together).

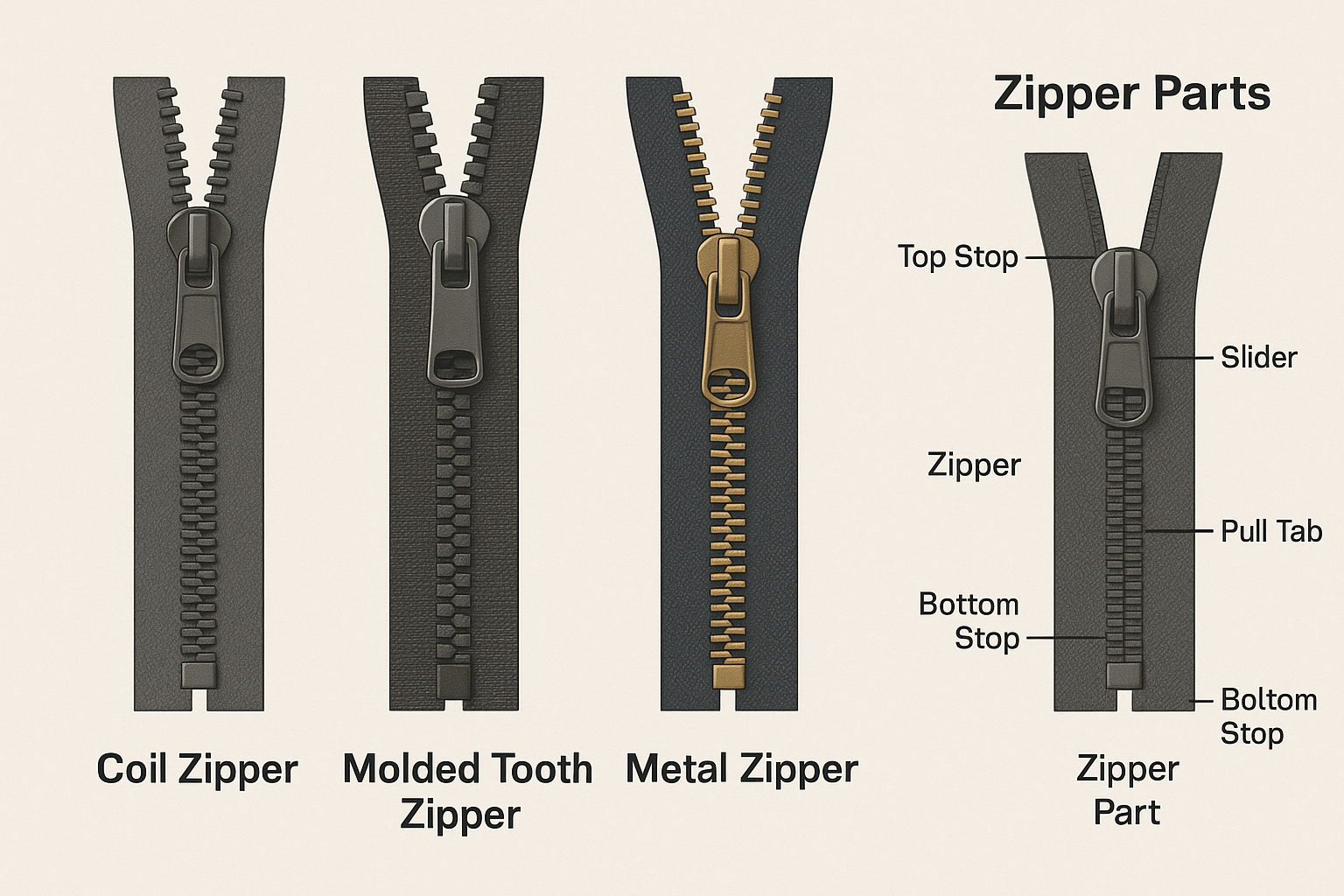

In coil zippers, helically wound nylon or polyester filaments absorb load elastically, distributing stress uniformly along the spiral. Metal and molded-tooth zippers behave differently—they rely on rigid interlocking points, where misalignment or wear can create stress concentrations. That’s why manufacturing tolerance is critical.

At LenZip, engineers test every zipper design to ASTM D2061, which measures chain strength, slider resistance, and stop retention. Zippers are repeatedly pulled until failure to calculate their true tensile load capacity. This level of testing ensures a zipper not only closes securely but maintains functionality after thousands of open–close cycles.

LenZip’s laboratories also apply fatigue testing and environmental cycling—subjecting zippers to alternating humidity, UV light, and temperature extremes—to replicate real-world wear. These evaluations provide the data that drive material and coating decisions.

Design Variables That Affect Durability

Durability begins with choosing the right material combination. Nylon and polyester tapes dominate the zipper world, each with specific mechanical advantages. LenZip’s nylon vs. polyester analysis notes that nylon offers higher elongation and impact resistance, while polyester provides superior UV and dimensional stability.

For outdoor, marine, or safety applications, polyester’s low moisture absorption makes it ideal. For flexible seams, curved edges, or garments requiring mobility, nylon tapes and coils excel.

Zipper teeth materials also determine long-term strength:

- Metal teeth (brass, aluminum, nickel) are extremely strong in tensile and bite force.

- Molded plastic teeth offer corrosion resistance and reduced weight.

- Coil teeth provide flexibility for contoured seams.

The interface between teeth and tape—called the anchor zone—is another point of engineering focus. LenZip’s review of zipper materials and finishes explains how specialized adhesives and weaving patterns keep the tape and chain aligned under stress.

Gauge size, or the width of closed teeth, influences load distribution. A #10 zipper can handle roughly four times the tensile force of a #3. For heavy canvas, luggage, or marine fabric, a larger gauge is essential. Lighter applications—like apparel or technical packs—favor #3 to #5 for drape and flexibility. Refer to LenZip’s Zipper Gauge & Chain Size Chart for load correlations.

Tape construction is equally important. Polyester warp threads and dense weft spacing prevent seam distortion. Stitch integration must follow precise guidelines to maintain structural balance. Incorrect thread tension can reduce zipper lifespan by 40%.

Protective coatings add another layer of defense. Nickel-free plating prevents oxidation in humid environments. For marine fabricators, LenZip’s polypropylene vs. polyester comparison highlights polymer options that maintain strength after prolonged UV and salt exposure.

How Zipper Design Translates to Real-World Longevity

Longevity depends not just on raw strength but on a zipper’s ability to resist fatigue, corrosion, and dimensional distortion. During thousands of open–close cycles, the slider acts like a traveling press. Each pass exerts compression and shear along the chain. The best zippers manage these forces through micro-engineered curvature and surface finish.

In LenZip’s heavy-duty product line, sliders are designed with precision chamfers that maintain consistent contact pressure across teeth. This prevents torque build-up and uneven wear—a common cause of jamming or slider spread.

Environmental resilience defines how long a zipper will survive outside the lab. Exposure to UV rays, salt air, or temperature fluctuations accelerates degradation. That’s why LenZip uses stabilized polymers and anti-corrosion plating that meet both ASTM D6775 tensile tests and MIL-SPEC durability standards.

For apparel and gear makers, longevity also means maintaining the right aesthetic over time. Discoloration, oxidation, or material stiffness can all signal chemical imbalance. LenZip’s finishing processes ensure consistent sheen and color retention across production batches—vital for OEM consistency.

Comparing Zipper Designs by Application

Different environments impose unique mechanical and chemical stresses on zippers. Designing with these factors in mind ensures longevity and compliance.

Application | Design Priorities | Ideal Construction | Gauge | Common Uses |

Marine | Salt, UV, moisture protection | Polyester or nylon coil with Delrin® sliders | #8–#10 | Boat covers, marine enclosures |

Automotive | Heat stability, precise alignment | Brass or plated-metal teeth on polyester tape | #5–#8 | Seat covers, dashboards, convertible tops |

Outdoor Gear | Lightweight flexibility | Nylon coil with UV-stable coating | #3–#5 | Tents, bags, performance apparel |

Industrial | Maximum tensile load, abrasion resistance | Molded plastic or metal teeth on reinforced tape | #10+ | Canvas shelters, machinery covers |

As LenZip’s marine industry overview emphasizes, using the correct tape and slider for the environment can double product lifespan. For example, Delrin sliders in coil zippers outperform standard metal sliders in saltwater because they resist oxidation.

Automotive interiors often use LenZip’s engineered brass zippers, chosen for precise tooth tolerances that ensure silent operation and resistance to heat cycling.

Outdoor products benefit from coil zippers’ flexibility, especially in curved seams. The light coil construction allows seamless integration into tent fabric, backpacks, or technical jackets without warping under tension.

Testing and Standards That Define Zipper Quality

Testing is where engineering meets reality. A zipper may look perfect, but only controlled data reveals whether it will perform over time.

The ASTM D2061 test suite defines more than nine distinct evaluations, including chain tensile strength, stop holding power, slider fatigue, and resistance to cushioned compression. These tests simulate years of real-world wear within days.

Some sectors require additional certifications. Marine applications reference ISO 12402 for buoyancy and safety gear. Fire-retardant clothing adheres to NFPA 1971 and 16 CFR Part 1610 for flammability. LenZip zippers often meet or exceed these through proprietary coatings and alloy treatments verified in-house.

LenZip’s Zipper Testing Standards detail how zippers are evaluated through multi-axis load simulations. Beyond static pulls, engineers test sliders under repetitive stress at varying angles, replicating how garments or covers move in use. The data informs continuous process improvement and ensures every production lot aligns with previous performance results.

Because all production is domestic, LenZip can adjust parameters rapidly—tape tension, slider clearance, tooth pitch—to meet client-specific loads. That’s one advantage of U.S.-based manufacturing that global competitors can’t match, as discussed in U.S.-Made Zippers Are Gaining Ground Against Global Brands.

Engineering Insights: Why Zipper Failures Happen

Even top-quality zippers can fail if mismatched to their application. Most failures stem from predictable causes that engineering can prevent.

- Tooth fracture or pull-off: Often due to excessive transverse loads or shallow tooth undercuts. Proper gauge selection and alloy choice prevent this.

- Slider distortion: Caused by unbalanced pull angles or torsional twisting at the tab pivot. Reinforced slider geometry helps maintain alignment.

- Tape fraying or detachment: Results from overstitching or incompatible thread tension. LenZip’s tape specifications define stitch density to minimize this risk.

LenZip’s failure analysis process isolates each variable—load angle, temperature, and stitch pattern—to determine exact break points. This feedback loop allows continual refinement of tooth shape, tape bonding, and plating composition.

Corrosion is another enemy of longevity. When dissimilar metals meet moisture, galvanic reactions erode the joint. LenZip’s materials guide details how stainless, nickel-free, and polymer coatings neutralize these reactions before they start.

How LenZip Engineers Reliability

Reliability at LenZip is rooted in vertical integration. Controlling every stage—from alloy casting to synthetic tape weaving—gives engineers command over performance variables. Every zipper is built under consistent environmental conditions, eliminating the inconsistencies seen in offshore production.

In LenZip’s Custom-Fit Program (link), OEM partners collaborate directly with engineering teams to fine-tune gauge, slider composition, and tape flexibility. That hands-on customization ensures precise performance whether the zipper is destined for a boat enclosure, protective suit, or industrial shelter.

LenZip also invests in sustainability. By researching bio-based polymers and recycled metal alloys, the company continues to reduce environmental impact without sacrificing durability. This philosophy—performance and responsibility combined—is central to Why Choose LenZip.

Quality assurance doesn’t stop after production. Random samples from each batch undergo stress-to-failure testing, UV exposure, and corrosion cycles to confirm performance benchmarks. If one variable drifts outside tolerance, corrective adjustments occur before shipment. That’s what makes LenZip one of the most trusted names in zipper engineering across North America.

Conclusion — Engineering Strength from the Start

The strength and lifespan of a zipper begin with design, not assembly. Every variable—geometry, gauge, slider pressure, and coating—works together to create reliability. When engineered correctly, a zipper doesn’t just close; it performs as an integral structural component of the product.

At LenZip Manufacturing, every zipper is built to meet specific environmental and mechanical conditions, whether for marine fabricators, industrial gear, or technical apparel. OEM partners benefit from decades of American engineering experience, responsive production, and rigorous ASTM-verified testing.

For a deeper look into zipper performance standards, explore LenZip’s Zipper Testing Standards and Zipper Materials & Finishes.

Learn more: Visit LenZip’s Technical Resources to see how U.S. engineering, testing, and customization come together to deliver zippers that last a lifetime.

Frequently Asked Questions

What determines a zipper’s tensile strength?

Tooth geometry, slider pressure, and tape construction define tensile strength. ASTM D2061 outlines the test method for measuring maximum load before failure.

How do material choices affect longevity?

Metals resist wear but can corrode; nylon resists flexural fatigue; polyester holds its shape under heat but may degrade under prolonged UV. LenZip’s material comparisons help match materials to environment.

What standards govern zipper quality?

ASTM D2061 remains the gold standard for strength testing, supplemented by ISO and NFPA protocols for specialized environments.

Why do marine zippers corrode?

Salt triggers electrochemical reactions between metals. LenZip’s marine zippers use polymer teeth and hydrophobic coatings to resist oxidation.

Can zippers be tested before full production?

Yes. LenZip performs pre-production tensile and fatigue tests to confirm design strength before scaling up.

How does LenZip maintain quality across batches?

Through in-house testing, strict gauge control, and full traceability of materials—from alloy batches to tape rolls—ensuring identical performance from the first unit to the last.