Where to Find Top-Quality American Zipper Manufacturers

Discover why American made zippers offer superior quality, reliability, and support US jobs. Explore types & find suppliers.

Discover why American made zippers, U.S. zipper manufacturers, and domestic heavy-duty zipper suppliers continue to outperform overseas competition in durability, engineering precision, and supply chain reliability. If you’re searching for high-performance metal zippers, molded plastic zippers, coil zippers, or Berry Amendment compliant fasteners, American manufacturers like LenZip deliver unmatched value rooted in technical expertise and long-standing craftsmanship.

American made zippers offer superior quality, reliability, and supply chain advantages that make them the preferred choice for manufacturers. By choosing domestic zippers, you benefit from superior materials like high-grade metals and premium polymers, a reliable supply chain with shorter lead times, and custom capabilities for orders of any size. For government contracts, these zippers also ensure Berry Amendment compliance. For deeper information on zipper materials, explore Zipper Materials & Finishes.

When you choose American-manufactured zippers, you’re not just buying a fastener—you’re investing in decades of manufacturing expertise and quality control standards that outperform imported alternatives.

The zipper industry has seen major shifts toward overseas production, but several U.S. companies continue to maintain domestic facilities and uphold the craftsmanship that built America’s reputation for quality. These companies serve critical industries including aerospace, automotive, marine, and military applications where failure isn’t an option. Many of these environments require high tensile strength, corrosion resistance, flame resistance, or chemical-resistant zipper options — areas where U.S. manufacturers excel. Learn more about how American-made options compare at U.S.-Made Zippers Are Gaining Ground.

For manufacturers dealing with unreliable overseas suppliers and inconsistent quality, American zipper companies offer a refreshing alternative. As one customer noted about LenZip zippers found on a decade-old gear pack: they were “still in great shape” after heavy use.

Why Choose American Made Zippers?

When you choose American made zippers, you’re investing in a tradition of craftsmanship, supporting your local community, and getting a product that simply works better. We’ve all experienced the frustration of a broken zipper. With American made zippers, those moments become rare exceptions rather than expected disappointments.

Supporting the local economy has a real impact. Buying American-made products helps create jobs, keeps manufacturing skills in our communities, and builds a stronger industrial foundation. But the benefits go deeper than economics. Superior quality is built into every American zipper through decades of refined manufacturing processes, ensuring the durability and reliability you need. To better understand zipper fundamentals, review the Zipper Parts & Teeth Guide.

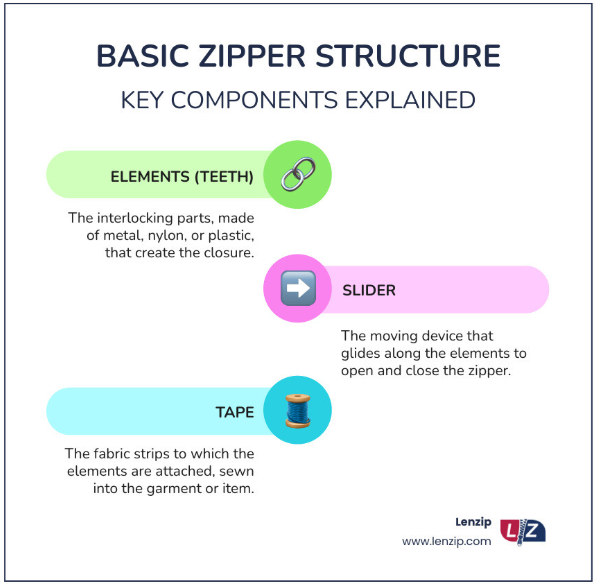

The difference is clear when you look at the structure of a quality zipper—every component works in harmony to create something that lasts. Domestic zippers also undergo tighter testing standards, which improves lifecycle performance across apparel, industrial covers, marine fabrications, and tactical gear.

Unpacking the Quality: Materials and Manufacturing

What makes American zippers different? It starts with high-grade metals like brass and aluminum and premium polymers that won’t corrode or crack under pressure. Domestic manufacturers use tighter tolerances, consistent element spacing, stronger tapes, and higher-quality sliders.

The real refinement happens inside U.S. facilities. American-made zippers are tested for tensile strength, fatigue, corrosion, and environmental exposure using standards such as ASTM, ISO, and military-grade testing protocols. If you want to see what real American zipper testing looks like, visit Inside Zipper Testing or How Zippers Are Tested.

At LenZip, our Los Angeles facility has been perfecting this craft for over 80 years. Our team’s experience ensures we can promise on-time delivery without the headaches of dealing with overseas suppliers. Our zipper testing and inspection methods catch problems before they reach you. In applications ranging from military gear to outdoor apparel, failure isn’t an option.

Want to learn more about how we maintain these standards? Explore additional manufacturing insights at LenZip vs YKK.

The Economic and Supply Chain Advantage

Choosing American is practical. Supporting U.S. jobs builds a supply chain you can rely on. When your supplier is a few states away instead of halfway around the world, everything is simpler.

Shorter lead times mean you’re not waiting months for an order. Need a rush order or an adjustment? Domestic manufacturers can respond quickly. Reduced shipping costs add up, especially when avoiding overseas freight, customs delays, and international uncertainty.

Environmental benefits also matter — domestic sourcing reduces carbon emissions associated with long-distance shipping.

Perhaps the biggest advantage is building strong relationships. As a family-run business, LenZip understands the importance of real communication. Customers continue working with us for decades because they know we deliver consistent quality. Learn more about the value of domestic sourcing at U.S.-Made Zippers Are Gaining Ground.

A Guide to Zipper Types from U.S. Manufacturers

Choosing the right zipper is crucial. Understanding the different types available from American zipper manufacturers makes all the difference. Whether you need something rugged for industrial gear or elegant for luxury fashion, American made zippers deliver dependable performance.

Every zipper has teeth (or elements), a slider that opens and closes the chain, and tape that holds everything together. Knowing these basics helps streamline communication with suppliers. Explore zipper terminology in the LenZip Zipper Glossary.

American manufacturers excel in customization — they can produce small quantities, unusual lengths, specialty pullers, and rare finishes. LenZip can make virtually any zipper in any length and color, even quantities as small as one. For cut-to-length zipper needs, see Custom Fit: Cut-to-Length Zippers.

Metal Zippers

Metal zippers are the toughest in the zipper family, built from individual metal teeth crimped onto strong tape. These zippers handle extreme stress and deliver classic appeal. LenZip crafts them from brass, aluminum, nickel, and gunmetal finishes.

For a comparison of brass vs aluminum, visit:

Brass vs Aluminum Zippers.

You’ll find these zippers on heavy-duty jackets, rugged luggage, industrial gear, and applications where failure isn’t an option.

Key Industries Relying on U.S.-Made Zippers

Industries relying on high-performance fasteners choose American zippers for consistency and safety. These include:

Military & tactical

Firefighting & protective apparel

Aerospace flight textiles

Marine fabrication

Automotive interiors

Industrial covers & tents

Outdoor gear & technical apparel

To explore industrial applications, visit Zippers for Protective Covers & Enclosures.

For aerospace applications, refer to:

Aerospace Zippers.

The Berry Amendment and Military-Grade American Made Zippers

For DoD contracts, the Berry Amendment requires 100% U.S. sourcing for textiles and components, including zippers. That means tactical gear, firefighting equipment, protective suits, and uniforms must use American-made zippers.

LenZip manufactures fully compliant Berry Amendment zippers. Learn more at:

Military-Grade Zippers.

Coil Zippers

Coil zippers bring flexibility and smooth operation. Made from continuous spirals of nylon or polyester, they work well for lightweight apparel, gear pockets, upholstery, and curved seams.

For comparisons, visit Coil vs Molded Zippers.

To compare coil materials, visit:

Nylon vs Polyester vs Polypropylene.

Molded Plastic Zippers

Molded plastic zippers are engineered for extreme durability. Each plastic tooth is molded directly onto the tape, creating a strong, corrosion-resistant chain ideal for marine, outdoor, and industrial applications.

Learn more about marine-grade zippers here:

Marine & Outdoor Zippers.

Aerospace, Automotive, and Marine

Aerospace requires zippers that withstand temperature extremes and pressure changes. Automotive interiors need durable, fade-resistant zippers. Marine environments require corrosion-proof, UV-resistant molded zippers.

See aerospace-grade solutions at:

Aerospace Zippers.

For automotive, refer to:

Why Zipper Quality Matters in Automotive Interiors.

Request custom solutions at

Request a Quote.

High-End Apparel and Outdoor Gear

High-end designers and technical outdoor gear brands choose American-made zippers because premium products demand premium components.

Outdoor performance requires zippers that withstand abrasion, moisture, freezing conditions, and repeated strain. Visit Choosing the Right Zipper for Jackets & Outerwear for guidance.

How to Source and Identify Genuine American Zippers

Many companies claim to be “American” while manufacturing overseas. True U.S. zipper manufacturers disclose their physical facilities, staff, and production capabilities. Verify the origins by reviewing the About Us page.

What to Look for in a Supplier

Look for decades of experience, domestic manufacturing, technical expertise, open communication, accurate lead times, and the ability to produce custom zippers in both small and large quantities.

Anatomy of a Tough Zipper: Materials and Types

Material selection determines whether a zipper handles UV, salt water, chemicals, extreme heat, or heavy mechanical loads. Heavy-duty zipper engineering begins with choosing the right material.

Explore more in the Zipper Material Guide.

Certifications and Verifying “Made in the USA”

Berry Amendment compliance and FTC “Made in USA” claims ensure authenticity and trustworthy domestic production. See additional insights at:

U.S.-Made Zipper Guide.

Conclusion: Invest in Quality with an American Zipper Company

Choosing American made zippers is a smart investment in quality, reliability, and the future of American manufacturing. Domestic zipper manufacturers deliver superior materials, craftsmanship, and performance.

Explore American-made zipper options here:

LenZip Products

Start your project today:

Request a Quote

FAQ — American-Made Zippers & U.S. Zipper Manufacturers

1. What makes American-made zippers better than imported ones?

American-made zippers are manufactured with higher-grade metals, stronger polyester or nylon tapes, and more durable molded polymers. U.S. zipper manufacturers follow strict ASTM and ISO testing standards, ensuring consistent tensile strength, corrosion resistance, and long-term reliability. Domestic production also eliminates the quality fluctuations common in overseas imports.

2. Are American-made zippers Berry Amendment compliant?

Yes — many U.S. zipper manufacturers, including LenZip, produce Berry Amendment compliant zippers. These are required for Department of Defense (DoD) textile procurement and must be sourced entirely within the United States.

3. Which industries rely most on American-made zippers?

Industries with high safety or performance requirements rely heavily on U.S.-made zippers, including:

• Military & tactical gear

• Fire-resistant and protective apparel

• Aerospace and aviation textiles

• Automotive interiors and RV components

• Marine fabrication and outdoor equipment

• Industrial covers, containment curtains, and tents

These sectors choose domestic zippers due to their reliability under stress, heat, cold, corrosion, chemicals, and UV exposure.

4. Can I order custom U.S.-made zippers in small quantities?

Yes. American manufacturers like LenZip can produce custom zippers in quantities as low as one. This includes custom lengths, colors, sliders, pulls, tape materials, and specialty configurations — ideal for prototypes, repairs, limited runs, or specialty equipment.

5. What types of zippers do American manufacturers make?

Domestic zipper companies produce:

• Metal zippers (brass, aluminum, nickel, stainless steel)

• Molded plastic zippers for marine and outdoor use

• Nylon and polyester coil zippers

• Invisible and reverse-coil zippers

• Heavy-duty industrial zippers

• Fire-resistant, airtight, and chemical-resistant closures

This range supports everything from high-end fashion to industrial-grade equipment covers.

6. How do I verify that a zipper is truly made in the USA?

Check the manufacturer’s website for clear statements about domestic production, review their About Us page, and confirm whether they follow FTC “Made in USA” guidelines. For military applications, look for Berry Amendment certification. If you’re unsure, contact the manufacturer directly — legitimate domestic companies will gladly confirm.

7. Are U.S.-made zippers more expensive?

They may cost slightly more upfront, but the long-term value is higher. U.S.-made zippers last significantly longer, reduce failures, prevent returns, and eliminate supply chain complications. Many manufacturers report American zippers lasting 10+ years in heavy-use environments — something rarely seen in offshore alternatives.

8. Are American-made zippers better for marine and outdoor applications?

Yes. U.S. manufacturers produce high-performance molded plastic zippers that withstand UV exposure, saltwater corrosion, temperature extremes, and heavy abrasion. Marine fabricators and outdoor gear brands consistently choose American molded zippers for their longevity.

9. Can American manufacturers produce Berry-compliant zippers for tactical gear?

Absolutely. Companies like LenZip specialize in Berry-compliant military zippers, used for plate carriers, flight suits, field shelters, FR gear, PPE, and other tactical textiles. These zippers meet strict performance and sourcing requirements.

10. What is the lead time for American-made custom zippers?

Lead times are significantly faster than overseas production. While offshore orders may take months, domestic suppliers can often deliver prototypes in days and production runs in a few weeks — with more consistent scheduling and communication.

Your Partner in Production

We understand that every project is unique, which is why we offer the flexibility you need. Our B2B focus means we can support your business with options that work for you, including minimums as low as 25 units. We are not just a supplier; we are your partner, committed to helping you find the right solution to fit your specific requirements.

Let’s Find the Right Solution for You

Ready to upgrade to the Lenzip standard? We’re here to help.

Talk to a representative today. We’ll help you find the right solution for your project

Call us at (847) 368-9000 or request a quote today.