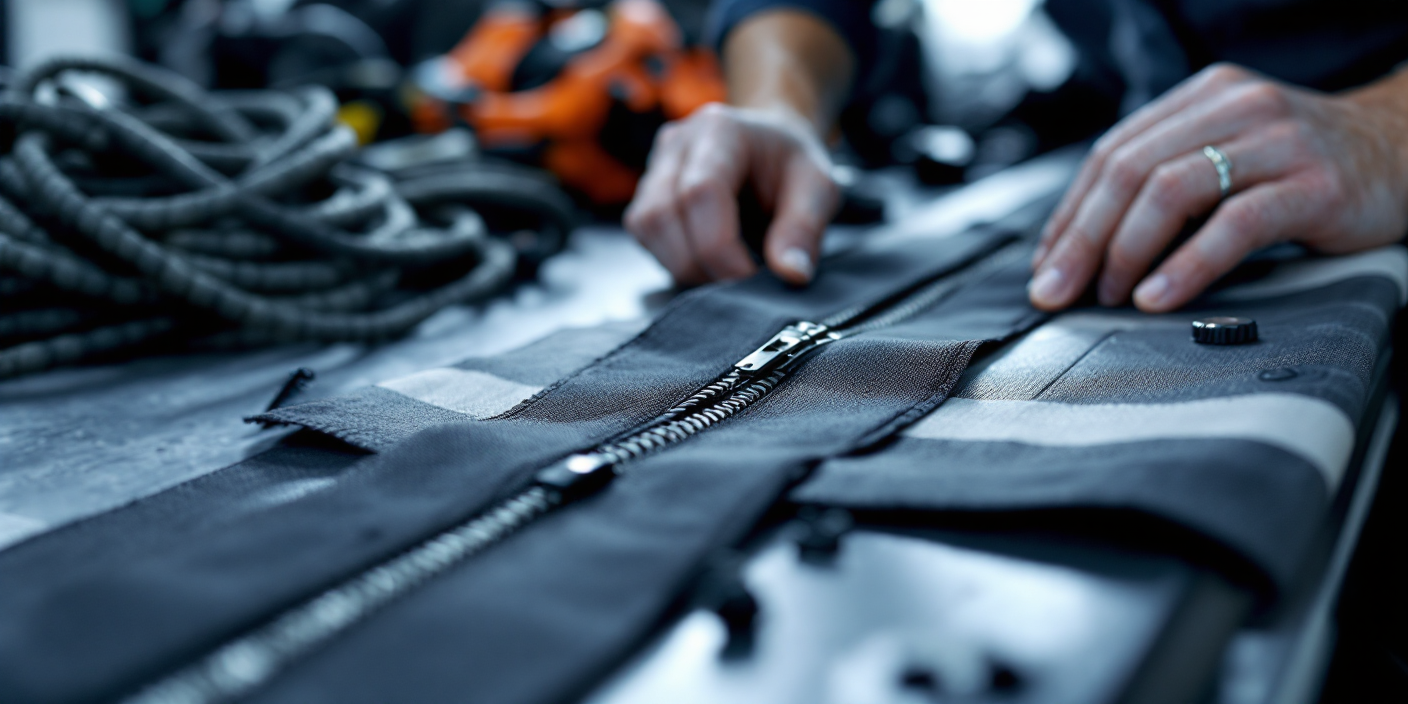

When a boat-cover zipper seizes or a dry-suit entry jams with sand, you don’t just replace parts—you lose days, quality, and trust. Lenzip engineers marine-grade closures that keep operating through salt spray, UV exposure, grit, and freeze-thaw cycles—so your covers, enclosures, and gear perform as long as your brand promises.

- Corrosion-resistant hardware (stainless or zinc-free alloys) on ASTM B117: 500+ hrs salt fog with no functional impairment.

- UV-stable TPU/PU-coated, low-wick polyester tapes on ASTM G154: ≥85% tensile retention after 1,000 hrs.

- Cold-flex validated: smooth operation through −25 °C cycling; target glide forces 50–75 N open / 40–60 N close (clean/dry), with acceptable increases when wet or lightly contaminated.

Explore: Marine Fabricators · Outdoor Gear · Tents & Shelters

Built for Salt, Sun, and Sand

Marine environments combine three destructive forces: chloride ions, high-energy UV, and abrasive grit. Standard zippers fail from galvanic corrosion, UV-embrittled tapes, and debris that binds sliders. Lenzip changes the equation with materials and geometries designed to resist those exact stressors.

- Corrosion-safe metals & finishes (stainless, zinc-free alloys, passivation) help prevent seizing in salt exposure. See: Preventing Marine Corrosion

- UV-stable TPU/PU coatings over low-wick polyester minimize capillary ingress and extend outdoor life. See: UV Impacts on Outdoor Zippers

- Anti-jam element profiles + polished slider interiors lower glide force even with light sand or salt residue.

Related resources: Heavy-Duty Zippers · Zipper Materials & Finishes

Smooth Operation—Wet or Dry

A good marine zipper isn’t “good” if it only works on a bench. We design for contamination, fabric tension, misalignment at corners, and temperature swing.

- Low-friction tooth faces and tuned slider channels reduce binding under load.

- Wide-entry sliders help forgive misalignment on canvas/vinyl.

- Field-safe lubricants (paraffin/beeswax or dry-film fluoropolymer) maintain glide without trapping grit. See care notes: Zipper Maintenance & Care

Choose the Right Seal & Gauge

Match seal performance to the job (avoid over- or under-specifying).

- Water-resistant chain for covers/enclosures that must shed rain/spray (IPX4–IPX6-type exposure).

- Airtight/watertight constructions for dry suits/inflatables where pressure or submersion matters (up to application-specific kPa).

Gauges: #5 for lighter gear/cushions · #8/#10 for marine canvas and enclosures · larger formats for long spans/high wind load.

Parts & formats: Open-End · Closed-End · Two-Way Open-End · Right-Hand Open-End

Integration with Canvas, Vinyl, and Coated Fabrics

We support both sewn and welded builds—pick what your product and process demand.

- Sewn: UV-resistant polyester/PTFE thread, double/triple rows, edge sealing to block stitch-line wicking.

- RF/heat-sealed: TPU/PU-coated tapes bond to TPU/PU/PVC-coated substrates for needle-hole-free seams. Guidance: RF-Weld Integration · Continuous vs. Finished

Chain supply & components: Continuous Zippers · Sliders · All Products

Tested for Marine & Outdoor Reality

We publish methods and acceptance targets so engineering and QA can qualify with confidence.

- Environmental: salt/fog exposure (ASTM B117), UV/weathering (ASTM G154), cold-flex, heat aging

- Mechanical: cycle/glide-force, abrasion at tape edges (Taber/Martindale), seam retention

- Documentation: acceptance targets, lot traceability, CAD/datasheets

See how we test: Zipper Testing Standards · How Zippers Are Tested · Zipper Load Testing Explained

Applications We Support

- Boat covers/enclosures, dodgers & biminis (wind load + UV + spray)

- Sail covers & rigging bags (abrasion + salt + packability)

- Expedition tents & outdoor structures (UV, cold-flex, high cycles)

- Dry suits & marine PPE (airtight/watertight seams under pressure)

Browse industries: Marine Fabricators · Tents · Outdoor Gear

Care & Serviceability (Field-Smart)

Rinse after salt exposure; brush teeth/slider; dry before storage. Use wax (metal) or dry-film (coil/resin); avoid silicone in sandy use. Replace worn sliders to extend chain life; keep spares on hand. More: Maintenance & Care

Seal Your Marine/Outdoor Spec with Lenzip

Send your fabric, environmental conditions (salt/UV/cold), and target performance (water-resistant vs airtight, gauge, cycle expectations). We’ll return a spec-matched construction (tape/coating, chain size, slider/hardware), integration guidance (sewn or RF/heat-sealed), and QC targets you can hand to production. U.S.-owned • Engineering support • Minimums as low as 25 units.

- Request a Marine/Outdoor Spec Match → https://lenzip.com/request-a-quote/

- Quick help: Customer Support → https://lenzip.com/customer-support/

Explore components: Custom Zippers · Sliders · Continuous Zippers · All Products