When hardware sees 30,000 ft, rapid pressurization cycles, and thermal swings that can exceed 180 °C in minutes, closures become performance parts—not conveniences. Lenzip engineers aerospace-grade custom zippers for temperature extremes, pressure control, vibration, and corrosion exposure, validated with environmental testing, and built to tight tolerances. Whether you’re integrating into coated technical fabrics, designing pressure interfaces, or managing thermal shock, we deliver consistent sealing, documented performance, and lot-level traceability—plus compatible sliders and continuous chain from the same source.

Built for Altitude, Thermal Swing, and Vibration

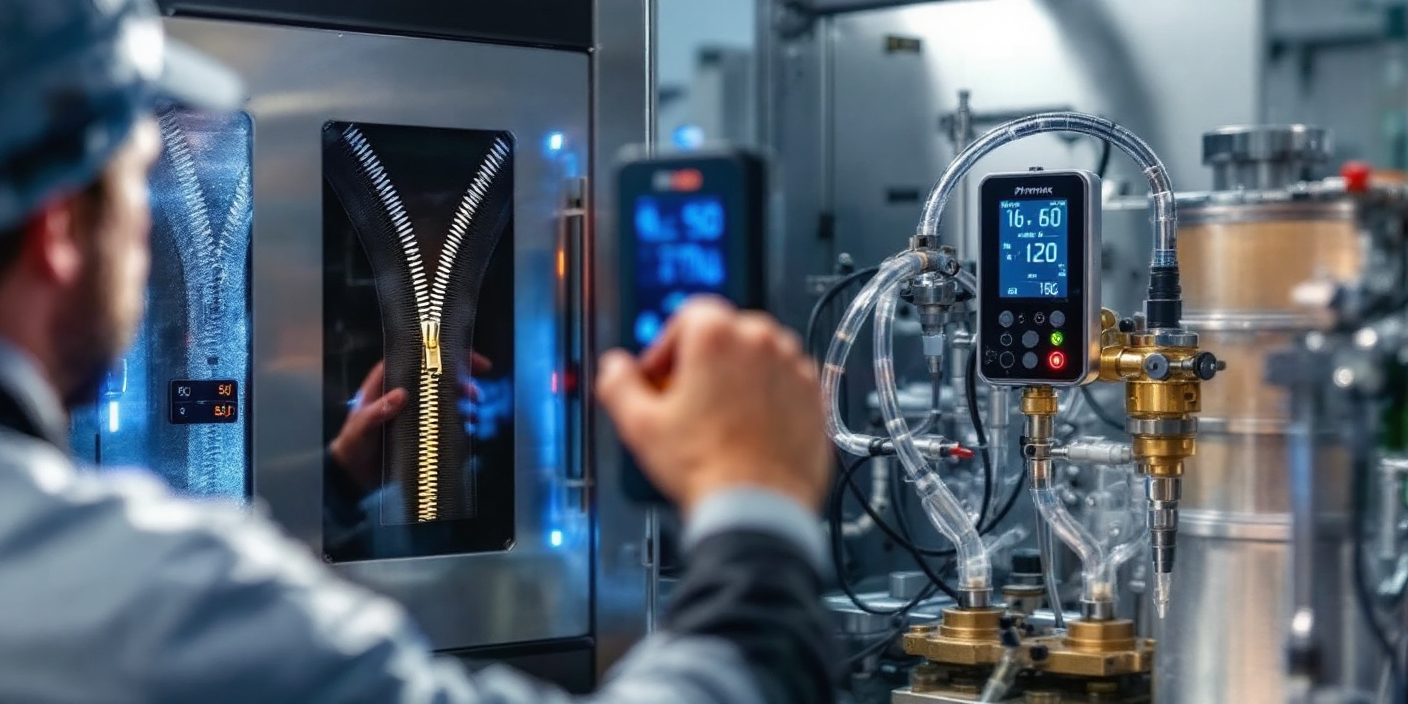

- Validated thermal cycling between −60 °C and +120 °C with controlled ramp/hold profiles.

- Cold-flex at low temps to verify no cracking and preserved interlock; heat aging to confirm dimensional stability after hundreds of hours >100 °C.

- Glide-force stability tracked pre/post exposure (thermal, vibration, humidity, salt fog) to keep operation within tight bands across service life.

Thermal Cycling & Shock Resilience

Aerospace assemblies face gradual cycling and abrupt shock. We qualify closures under both: gradual cycles expose material drift; shock protocols surface interface weaknesses. Result: geometry and function remain within spec through rapid altitude changes and emergency decompression scenarios.

Glide Force—Stable When It Matters

Operators wear gloves and work against the clock. We tune tooth geometry, finishes, and tolerances so opening/closing effort stays predictable after environmental exposure—typically maintaining variation within low single-digit newtons from baseline after test sequences.

Pressure-Capable When Required

Not every application needs airtightness. We help you match seal level to mission:

- Water-resistant: moisture protection for covers and bags—no pressure hold.

- Waterproof: liquid exclusion under hydrostatic load—limited gas leakage acceptable.

- Airtight/pressure-rated: precision seals + tight-tolerance chain for leak-hold performance; validated via pressure-decay/tracer gas and burst testing with documented acceptance criteria.

Materials That Cut Mass and Fight Corrosion

Weight matters—and so does longevity. Pair the right custom zipper construction with:

- Hardware options: passivated stainless (marine-grade available), anodized aluminum, or engineered polymers for mass-critical builds.

- Surface treatments: passivation and anti-seize to prevent galling and preserve serviceability after exposure.

- Tapes: UV-stabilized TPU/PU over low-wick substrates; accelerated UV/condensation testing (QUV/QUVA) for multi-year equivalence; hydrophobic constructions to limit capillary moisture migration.

Tolerances & Repeatability for OEM Programs

Interchangeability depends on control.

- Chain pitch held to ±0.1 mm (tighter available per program).

- Tape width/flatness controlled (typ. ±0.5 mm) to support RF/heat-seal envelopes.

- SPC, in-process inspection, and vision metrology back every lot.

Integration to Technical Fabrics (Stitch vs Weld)

Stitching is robust for breathable builds; sealed systems demand welding.

- RF welding to PVC/PU-coated fabrics for hermetic seams—no needle perforations.

- Heat-seal/hot-air/impulse pathways for compatible thermoplastics.

- We provide parameter windows and destructive testing targets (peel 3–10 N/cm typical; shear specified per substrate/geometry) after environmental conditioning.

QA, Documentation & Traceability

Lot-unique IDs tie finished goods to raw-material certs, in-process checks, and final tests. Shipments include Certificates of Conformance; extended packages (test reports, REACH/RoHS statements, material data) are available for program qualification.

Seal Your Aerospace Spec with Lenzip

Share your thermal targets, pressure/airtight requirements, substrates, and gauge/format constraints. We’ll return a spec-matched construction (tape/coating, chain size, slider/hardware), weld/assembly guidance, and QC targets your team can hand to production. U.S.-owned • Engineering support • Minimums as low as 25 units.

- Request an Aerospace Spec Match → Request a Quote

- Quick help: Customer Support

- Browse components: Custom Zippers · Sliders · Continuous Zippers · All Products