Why Zipper Testing Frequency Determines Product Quality

Across apparel, marine fabrication, luggage manufacturing, protective covers, and industrial soft goods, zipper failure is one of the most expensive—and completely preventable—quality problems. A zipper that jams, separates, corrodes, or loses slider retention prematurely can ruin an entire production run or generate costly warranty claims. The best-designed textiles still fail in the field if the zipper test procedure, audit frequency, and measurement standards are not aligned with the product’s intended use.

This is why understanding how often zippers should be tested is a critical part of quality assurance. Zipper test frequency varies dramatically by industry, environment, material type, and expected load cycles. A zipper on a marine enclosure might require monthly corrosion audits, while an apparel zipper may only need quarterly fatigue testing. Heavy-duty industrial covers often require tensile testing on every batch.

Manufacturers rely on structured zipper quality audits—designed around risk, environment, and expected lifespan—to avoid zipper chain separation, slider fatigue, tooth deformation, and corrosion-related failures. Brands that require consistent performance increasingly turn to U.S. manufacturing expertise from LenZip, whose in-house testing, materials engineering, and technical standards exceed global benchmarks.

For a deeper look at the science behind failure modes, review How Zippers Are Tested for Strength, Corrosion, and Fatigue and the technical frameworks established through Zipper Engineering 101.

What a Zipper Test Measures: The Engineering Behind Test Scores

A zipper test is a standardized set of procedures used to measure zipper durability, zipper test score performance, fatigue resistance, corrosion tolerance, slider retention strength, and long-term reliability. These tests follow strict international protocols, commonly drawn from ASTM and ISO technical specifications.

Leading global standards include:

ASTM D2061 — Tensile strength, slider pull-off, chain separation

ASTM D2050 — Slider locking performance

ASTM D3477 — Corrosion and environmental resistance

ISO 12402-7 — Marine-grade hardware performance

ISO 9001/17025 — Auditing and quality management frameworks

Authoritative documentation can be reviewed through ASTM and the global standards catalog at ISO.

A zipper test evaluates mechanical behaviors such as:

Tensile Strength

Measured by the force required to break teeth, tape, or stops.

Cycle (Fatigue) Testing

Simulates real use by opening and closing the zipper 10,000–30,000 times.

See extended testing details at Zipper Load Testing Explained.

Salt-Spray / Corrosion Testing

Exposes zippers to high-salinity environments to replicate marine conditions.

Flex Testing

Determines whether coil, molded, or metal teeth deform under repeated bending.

Slider Retention & Pull-Off

Measures the force needed to detach or damage the slider.

Environmental Stress Simulation

UV exposure, humidity cycling, and temperature extremes can be added to custom test runs.

For a complete glossary of terms used in these procedures, consult the Zipper Terms You Should Know reference library.

How Zipper Test Scores Are Measured & Interpreted

To make zipper test results meaningful, measurements are evaluated against standardized pass/fail thresholds. These thresholds vary by industry and end-use.

Cycle Count (Fatigue)

A zipper test procedure may run 10,000, 20,000, or 30,000 cycles depending on product category. Marine-grade products often demand higher cycle counts.

Pull Force Values (Tensile)

Measured in pounds or Newtons. ASTM D2061 defines minimum acceptable forces for teeth, slider, stops, and tape.

Corrosion Results

After salt-spray exposure, the zipper must remain functional with no rust that impairs operation.

Slider Retention Measurements

A test confirms the slider does not unintentionally detach under defined force loads.

Visual Assessment

Inspectors evaluate tooth wear, tape fraying, chain waving, slider distortion, and surface degradation.

All of these results align with the guidance found in Zipper Testing Standards and the detailed specifications outlined in the How to Read Zipper Spec Sheets resource.

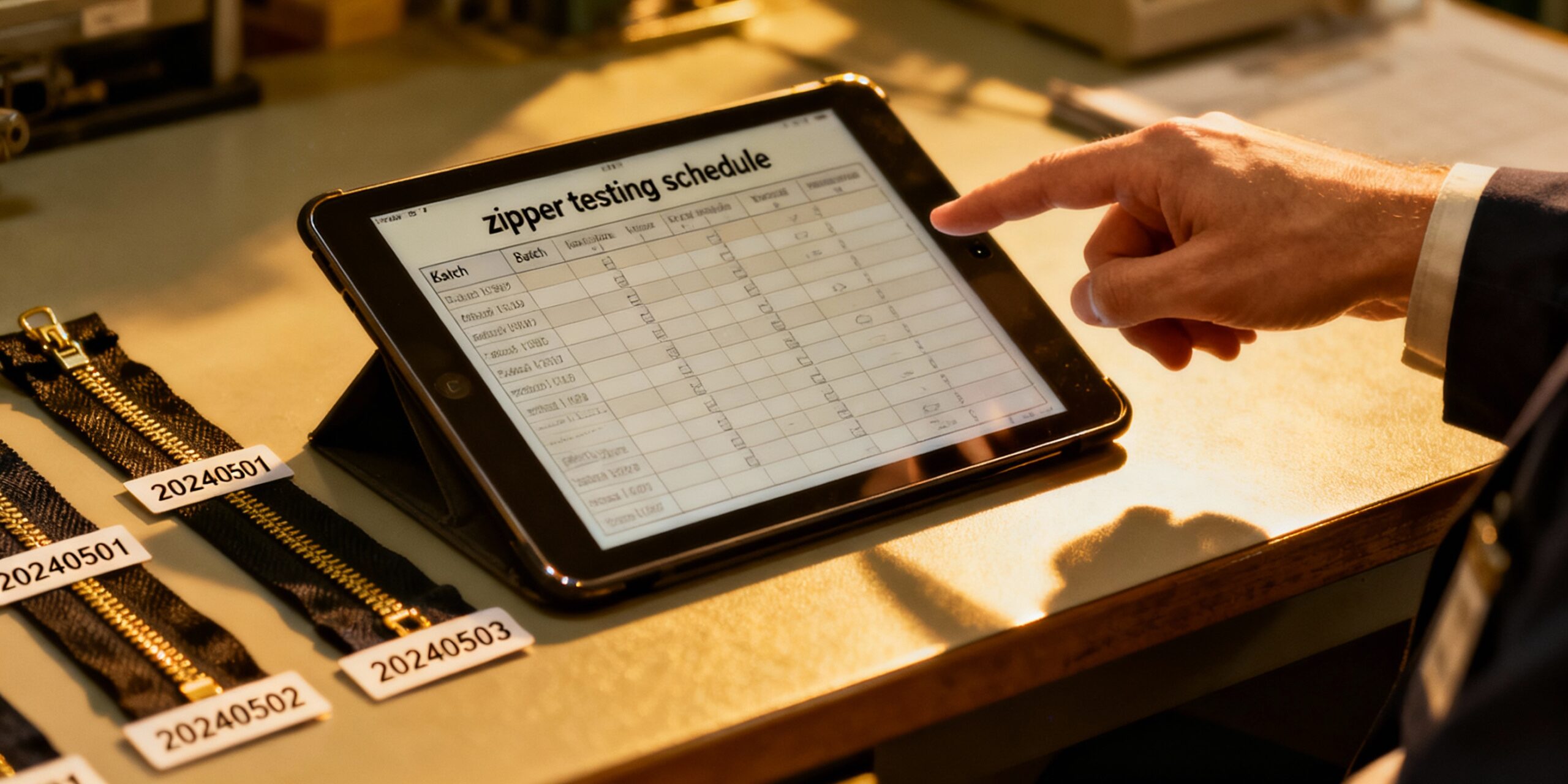

How Often Should Zippers Be Tested? Audit Frequency by Industry

Testing frequency depends heavily on environment, load, and product category. Below is an industry-specific breakdown.

Apparel & Fashion Manufacturing

Quarterly testing is standard.

Most apparel zippers use mid-weight fatigue cycles and tensile tests appropriate for jackets and outerwear. Supplemental testing is needed for coated tapes or water-resistant zipper constructions.

Explore apparel-related zipper types in Choosing the Right Zipper.

Outdoor Gear (Backpacks, Tents, Technical Packs)

Outdoor gear requires more aggressive fatigue testing.

Run tensile and cycle tests for every production batch, particularly for load-bearing seams.

Designers should evaluate gauge and material choices using the Zipper Gauge Chain Size Chart and Zipper Types Explained.

Marine & Saltwater Applications

Marine zippers require the most frequent testing—usually every batch or monthly.

Salt-spray and UV testing are essential.

Fabricators can reference guidelines at Marine Fabricators Industry Page.

Industrial Covers, Curtains & Protective Enclosures

Industrial soft goods require monthly tensile and cycle audits.

These applications often use #10 molded or metal zippers with extreme tension loads.

Integrate technical insights from Finding Industrial Strength Zippers.

Automotive & Transportation Interiors

Quarterly or per style cycle testing is common, especially for seat covers and restraint systems.

Design principles may resemble those outlined in Zipper Engineering 101.

Luggage, Duffel Bags & Travel Gear

High-duty-cycle products need fatigue tests per batch.

Handle stress, zipper length, and gauge selection should be validated using tools in the Zipper Materials & Finishes section.

Tactical, Military & High-Risk Environments

The strictest testing frequencies apply here. Zippers in tactical packs, field shelters, or protective suits require both batch testing and additional tensile/cycle audits.

Browse the specialized page for field-grade performance at Military & Tactical Zippers.

All industries benefit from structured testing cycles, supported by technical insights across additional resources like the Zipper Tape Construction Guide and the Continuous Chain vs. Finished Zippers Overview.

Setting Up a Zipper Quality Audit Schedule for OEMs

A zipper audit plan must be structured, repeatable, and grounded in mathematical sampling logic. A thoughtful testing plan reduces failures, increases product reliability, and ensures supplier accountability.

Steps to Build a Quality Audit Schedule

Define a Sampling Framework: Establish batch sizes, production intervals, AQL thresholds, and risk categories.

Assign Test Methods: Use ASTM/ISO tensile, fatigue, corrosion, and slider retention tests appropriate for the product segment.

Set Routine Testing Cadence: Monthly for high-risk categories; quarterly or per run for apparel and luggage.

Use Pre-Shipment Verification: Validate zipper test scores before outbound shipment.

Collect Supplier Documentation: Require test certificates, measurement logs, and QC documentation.

Perform Annual Factory Audits: Validate supplier consistency using guidelines found on the LenZip Industry Page.

Revise Schedule Based on Failures: If field complaints increase, increase test frequency until stability returns.

Manufacturers seeking more detailed QC strategies often reference the advanced breakdowns in How Zippers Are Tested and application-specific insights in Choosing the Right Zipper.

Common Problems Identified Through Routine Testing

Zipper testing is effective because it exposes early signs of mechanical or environmental failure:

Slider Wear & Deformation

Slider fatigue often appears after high-cycle use.

Insights into slider geometry and compatibility appear in the Guide to Zipper Teeth, Sliders and Their Parts.

Tooth Fatigue & Breakage

Repeated stress can cause molded or metal teeth to deform or fracture.

Chain Separation

When the gauge is undersized or material is mismatched, teeth disengage under stress.

See examples in Zipper Teeth Not Closing.

Corrosion or Salt Damage

Marine environments accelerate oxidation and surface degradation.

Tape Wear or Delamination

UV, chemicals, or seam stress can cause the tape to unravel or weaken over time.

Routine audits help manufacturers pinpoint failure modes before they become widespread. Engineering references such as the Zipper Glossary and Zipper Engineering 101 deepen understanding of these mechanical phenomena.

When to Increase Testing Frequency

Some production environments require accelerated testing schedules:

New Materials, Designs, or Tape Substrates

Whenever a new polymer, slider design, or finishing method is introduced, testing frequency should increase temporarily—often to every lot.

New Supplier or Region Shift

Moving production to a new facility requires batch-by-batch auditing until statistical confidence is established.

Unexpected Field Failures

If warranty claims increase, fatigue and tensile tests should double until failure analysis confirms stability.

Extreme Climates or Harsh Use Cases

Arctic cold, tropical humidity, desert heat, or saltwater exposure justify additional corrosion, UV, and fatigue testing.

High-Tension or Load-Bearing Applications

Heavily loaded gear must be tested more frequently to mitigate chain separation and slider wear.

Relevant guidance appears throughout Finding Industrial Strength Zippers.

How LenZip Ensures Zippers Pass the Strictest Global Standards

LenZip’s U.S. engineering and testing methodology exceeds common commercial requirements. Each zipper is subjected to ASTM and ISO-aligned procedures, validated through tensile, fatigue, slider retention, and corrosion testing in their controlled test environment.

Manufacturers partner with LenZip because:

Their test machines simulate real-world use with high accuracy

Their material selection process eliminates weak links before production

Their in-house development team assists with customized audit schedules

Their U.S.-based production ensures consistency and fast failure analysis

Additional documentation and testing procedures can be explored in the Zipper Testing Standards Overview and Zipper Load Testing Explained.

Final Thoughts: Testing Schedules Protect Your Product and Brand

Zipper testing frequency is not a one-size-fits-all formula. It must reflect the product’s environment, expected strain, customer use patterns, and material complexity. Routine zipper audits ensure consistent performance, reduce warranty costs, and reinforce reputational trust.

With a proven record in technical zipper engineering and strict adherence to ASTM and ISO standards, LenZip remains the U.S. manufacturer OEMs trust for reliable, repeatable test performance and long-term product durability.

Frequently Asked Questions

What is a zipper test used for?

A zipper test measures tensile strength, cycle durability, corrosion resistance, slider retention, and overall operational reliability. See the Zipper Testing Standards for technical definitions.

How often do zippers need to be tested?

Apparel: quarterly.

Outdoor gear: each batch.

Marine: monthly.

Industrial covers: monthly.

Tactical gear: per batch plus periodic audits.

Guidance appears in Choosing the Right Zipper.

What happens if a zipper fails testing?

Engineers perform failure analysis, adjust materials or processes, and increase test frequency until corrective actions stabilize results. See Zipper Teeth Not Closing.

What is the best zipper test for durability?

Fatigue cycle testing combined with tensile and corrosion testing provides the most comprehensive reliability picture. Learn more at Zipper Load Testing Explained.

Do marine zippers require more frequent testing?

Yes. Saltwater exposure accelerates corrosion. Guidelines are available at the Marine Fabricators Resource.

What does a zipper test score represent?

It’s a quantified measure of force, cycle count, corrosion tolerance, and slider stability against ASTM/ISO standards. Reference the Zipper Testing Standards.

Are ASTM zipper tests legally required?

They are not always legally mandated but are widely adopted. Industry norms are found at ASTM.

How do manufacturers interpret zipper test results?

By scoring tensile, cycle, flex, corrosion, and slider retention results against documented thresholds. More detail appears in the Spec Sheet Reading Guide.

What is the difference between tensile and cycle testing?

Tensile measures breaking force; cycle tests simulate repeated operation. Both are required for a complete assessment. Examples appear in Zipper Engineering 101.

How often should suppliers themselves be audited?

At least annually, plus additional audits after failures or supplier changes. See the Industry Audit Resource.