Unzip Your Creativity:

Where to Find Unique Custom Zipper Pulls

Elevate your brand with custom zipper pulls! Discover top materials, design tips, and how they boost product appeal. Find your perfect pull.

In every high-performance garment, travel bag, or marine enclosure, small details define quality. Among those details, few components combine branding and functionality as effectively as a custom zipper pull. These compact design elements elevate products with tactile appeal, reinforce logos, and communicate craftsmanship at every touchpoint.

At LenZip USA—America’s longest-operating family-owned zipper manufacturer—custom zipper pulls are engineered with the same precision and material integrity as the zippers themselves. Whether you’re sourcing for technical apparel, industrial covers, or luxury handbags, LenZip integrates design, durability, and brand distinction into every puller we produce.

The Branding Power of Custom Zipper Pulls

A custom zipper pull isn’t just an accessory; it’s a micro billboard for your brand. Each pull transforms an ordinary closure into a tactile, visual reminder of your product’s quality. By imprinting your logo or brand name onto every zipper, you gain daily exposure and reinforce the trust customers associate with durability and design.

For OEMs in apparel, marine, or aerospace sectors, branded zipper pulls deliver more than aesthetic value. They serve as functional identifiers across production runs, simplify inventory tracking, and improve user experience—especially when paired with LenZip’s precision-engineered zipper teeth and sliders.

LenZip engineers offer full design customization, ensuring every pull aligns with your zipper type, gauge, and application. Whether it’s a sleek metallic pull embossed with your logo or a soft PVC pull in Pantone-matched colors, the result is a component that feels and functions like part of your identity.

Material Options: Engineering for Aesthetics and Performance

Choosing the right material for a custom zipper pull determines its lifespan, feel, and brand message. LenZip’s in-house material engineering team helps OEMs evaluate performance based on tensile strength, corrosion resistance, temperature exposure, and tactile feedback.

Metal Custom Zipper Pulls

Custom metal zipper pulls are the industry standard for high-end applications that demand precision and endurance. Crafted from zinc alloy, brass, or stainless steel, these pulls communicate premium quality and handle environmental stress better than plastic alternatives.

Zinc alloy offers the best balance between cost, formability, and finish options—making it ideal for detailed, 3D-embossed logo pulls. Brass pulls are prized for corrosion resistance and timeless aesthetic appeal, often seen in luxury handbags or leather goods. For extreme applications—marine, outdoor, or military—stainless steel resists rust, abrasion, and fatigue without compromise.

Electroplating expands visual versatility with more than 37 finish options, including antique brass, matte black, and polished nickel. This process adds a protective layer that enhances both durability and color retention—critical for marine and outdoor zippers exposed to UV, salt, or moisture.

LenZip’s zipper materials and finishes guide provides detailed information on how each coating impacts longevity, corrosion resistance, and visual tone.

Soft PVC Custom Zipper Pulls

When flexibility and color accuracy matter, soft PVC custom zipper pulls deliver creativity and cost efficiency. These are ideal for promotional products, sportswear, and children’s apparel—anywhere a soft touch and vibrant design are desired.

Soft PVC’s moldability allows for complex 2D and 3D shapes—logos, mascots, or miniature icons that tell your story. The material is water-resistant, flexible in cold conditions, and available with full Pantone color matching for precise brand consistency.

Newer eco-friendly versions made from recycled PVC or bio-based polymers reflect LenZip’s commitment to eco-engineered zippers and sustainable manufacturing. These pulls not only reduce environmental impact but align with green initiatives in modern apparel and packaging design.

Fabric and Leather Custom Zipper Pulls

For brands emphasizing authenticity and heritage, fabric and leather zipper pulls bring natural warmth to the design. Woven fabric pulls showcase printed or embroidered logos, offering lightweight flexibility perfect for upholstery applications, backpacks, or casual wear.

Leather pulls age gracefully, developing a patina that enhances over time. They suit premium outerwear, vintage-inspired bags, or rugged outdoor products. Each can be debossed, engraved, or heat-stamped for discreet yet impactful branding.

Even minimalist designs like cord pulls—commonly found on tactical packs or outdoor enclosures—can be customized with woven brand tabs, reflective coatings, or contrast stitching for visual differentiation.

Comparing Performance and Applications

Below is a simplified comparison of material categories and their typical use cases across LenZip’s global OEM base:

| Feature | Metal Pulls | Soft PVC Pulls | Fabric/Leather Pulls |

|---|---|---|---|

| Durability | Excellent – corrosion and fatigue resistant | Good – flexible, water-resistant | Moderate – tactile, eco-friendly |

| Finish Options | 37+ metal electroplated colors | Pantone-matched, 3D shapes | Natural tones, embossed textures |

| Best For | Premium apparel, luggage, industrial | Sportswear, kids’ apparel, promos | Heritage brands, eco lines |

Each selection integrates seamlessly with LenZip’s custom zipper assemblies and cut-to-length solutions for OEM production lines.

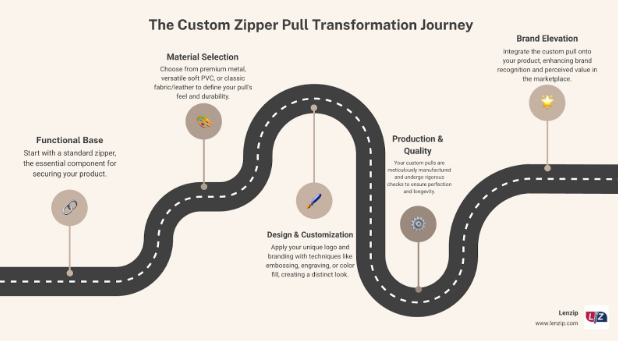

Designing Custom Zipper Pulls: The OEM Process

The creation of a custom zipper pull mirrors product development at scale—concept, design, prototyping, and testing. LenZip’s engineering-driven process minimizes trial-and-error, reducing lead time and tooling costs while maintaining precision.

- Concept & Artwork – OEMs supply vector-based artwork (AI, EPS, or PDF) with logo placement and dimensions. LenZip’s team assists in optimizing thickness and curvature for manufacturability.

- Material Selection – Based on intended use and environmental exposure, engineers recommend compatible materials and coatings, referencing zipper testing standards.

- Prototyping & Sampling – 3D modeling and limited-run casting ensure the prototype aligns with functional and visual expectations.

- Production & Quality Testing – Each pull is fatigue-tested alongside the zipper assembly to validate long-term performance under repeated cycles and environmental stress.

By maintaining complete vertical integration—from tape construction to finishing—LenZip guarantees consistent fit and alignment between pullers and chains across every production batch.

Color, Texture & Finishing Techniques

A zipper pull’s surface treatment directly influences perceived value. Electroplating, powder coating, or enameling adds distinct tone and texture. Color-filled or engraved logos reinforce brand memorability while protecting fine design lines from abrasion.

For fashion-forward clients, dual-finish combinations—such as matte base with glossy logo—offer dimensional contrast. Industrial OEMs, by contrast, favor low-glare coatings for environments where reflectivity can compromise safety or concealment, such as military and tactical gear.

Each finish is tested for corrosion and UV resistance following ASTM B117 and ISO 9227 protocols. Testing data is available on request via LenZip’s testing and quality assurance portal.

Sustainability and Supply Chain Confidence

In today’s globalized market, specifying U.S.-made zipper components offers distinct advantages in traceability, quality control, and delivery reliability. LenZip’s U.S. manufacturing eliminates offshore supply disruptions and shortens lead times for just-in-time OEM production.

Recycled alloys, low-emission coatings, and renewable polymer options align with sustainable design requirements under ISO 14001 frameworks. For brands pursuing ESG goals, LenZip provides documentation for recycled content, eco-safe PVC, and RoHS compliance across all custom pull lines.

How Custom Zipper Pulls Influence Consumer Perception

The tactile experience of a zipper pull shapes first impressions. Smooth motion, weighted feel, and visual detail create subconscious associations with reliability and craftsmanship. A custom logo zipper pull turns every closure into brand reinforcement—especially in products handled daily, from outerwear to luggage.

According to Textile World, small metal embellishments like branded zipper pulls can increase product perceived value by up to 15%. This makes them one of the most cost-effective branding investments available to OEMs.

When combined with precision-built metal or plastic zippers, the result is a closure system that not only performs flawlessly but also enhances brand equity and consumer trust.

Integration Across Industries

LenZip custom zipper pulls are featured in products across multiple sectors, including:

- Marine and Outdoor – corrosion-resistant stainless or brass pulls paired with water-resistant zippers for canvas enclosures and sail covers.

- Industrial Equipment and Covers – reinforced alloy pulls designed for strength under load.

- Fashion and Lifestyle – engraved logo pulls in gold or matte black to enhance premium apparel and handbags.

- Tactical, Safety, and Aerospace – non-reflective, high-tensile steel or TPU-coated pulls for extreme conditions.

Each segment benefits from custom-fit engineering, ensuring the pull, slider, and tape perform as a unified mechanical system.

Why OEMs Choose LenZip for Custom Pulls

LenZip’s heritage dates back to 1946, and every innovation since has focused on building reliability into the smallest details. With over seven decades of zipper manufacturing expertise, LenZip supports OEM partners through every development phase—from CAD modeling and sample validation to mass production.

Choosing a LenZip-engineered custom zipper pull means gaining access to:

- Proven U.S.-made quality

- Rapid prototyping and sample turnaround

- Expert support for RF-weldable, marine, and aerospace applications

- Seamless integration with existing zipper inventory

- Transparent pricing and traceable material sourcing

Each pull is built to endure thousands of cycles under real-world conditions—ensuring that your brand’s reputation holds firm, one zip at a time.

FAQs: Custom Zipper Pulls for OEM & Design Applications

What materials are best for durable custom zipper pulls?

Zinc alloy and stainless steel offer the best balance of strength, corrosion resistance, and detailed finish options. LenZip also manufactures eco-friendly PVC and recycled material pulls for sustainability-focused projects.

Can I add my logo or brand name to any zipper pull?

Yes. LenZip engineers specialize in custom logo zipper pulls using embossing, engraving, or enameling to match your branding and product line aesthetics.

Are soft PVC zipper pulls water-resistant?

Absolutely. Soft PVC is inherently water-resistant, making it ideal for marine, sports, and outdoor applications.

How does LenZip ensure color accuracy for custom pulls?

Every soft PVC and coated metal pull can be Pantone color matched to maintain brand consistency.

Do you offer small-batch or prototype runs?

Yes. LenZip provides short-run prototyping for new designs before large-scale production to validate feel, motion, and visual accuracy.

Can I request samples or a quote?

OEMs and designers can submit specifications directly through the LenZip quote request portal.